A new breed of floating offshore wind turbine foundations, designed to handle the largest wind turbines in the world, has received ABS approval in principle (AIP).

The Bassoe D-Floater technology is capable of carrying 15-megawatt (MW) turbines in some of the harshest environmental conditions.

Fifteen-megawatt turbines are the next generation of power producing systems and are as tall as the Eiffel Tower and can weigh upwards of 2,000 tons.

“ABS is proud to add the Bassoe D-Floater to its list of pioneering offshore floating innovations that we have been able to support. This list includes classification of the first and largest floating wind projects. Now we are able to support floating turbines capable of matching the capabilities of fixed bottom equivalents in scale and consequent generating capacity. ABS is leading the development of floating offshore wind capabilities globally,” said Lars Samuelsson, ABS Head, Global Floating Offshore Wind.

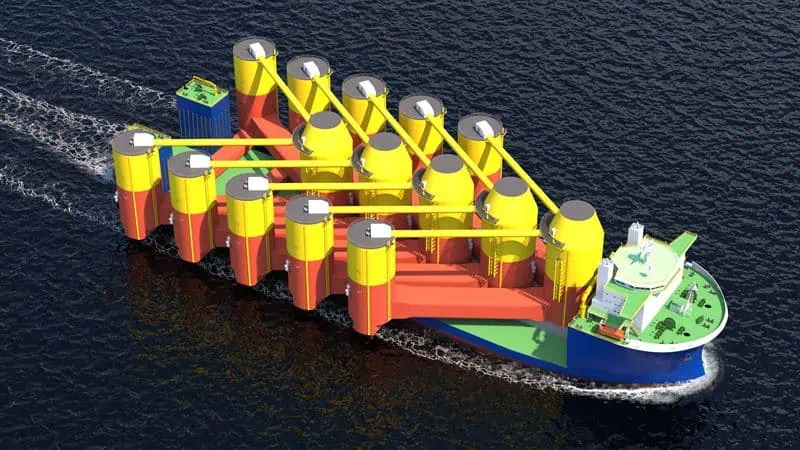

The D-Floater is a three column, semi-submersible unit with a Delta-shaped pontoon configuration that allows the stacking of foundations inside each other, facilitating transport of at least five completed foundations on a single, heavy lift transport vessel and efficient storage in the marshalling port. With a tow-out draft of less than 10 meters with the turbine installed, the design is intended to allow flexibility in “assembly port” selection and to allow quayside installation of the tower and turbine closer to the wind farm, in many cases.

“The D-Floater is a floating foundation designed for cost efficient fabrication and logistical solutions to meet the growing demand for renewable energy. Together with our parent company, CIMC Raffles, we will have the ability to deliver more than 50 D-Floaters per year. The D-Floater’s global supply capability complements our T-Floater that allows for local fabrication, and both concepts now have approval in principle from ABS,” said Tore Ulleland, Managing Director, Bassoe Technology.

The AIP verifies that the design is feasible for the intended application and, in principle, complies with the applicable requirements of the ABS Guide for Building and Classing Floating Offshore Wind Turbine Installations. When constructed, the D-Floater will qualify for the following ABS Class notations:

✠A1, Offshore Wind Turbine (Floating), Fatigue Life (FL (25)), Underwater Inspection in Lieu of Drydocking (UWILD), and Inventory of Hazardous Materials (IHM).

ABS has been instrumental in the formulation of global standards for wind platforms and for the design and fabrication of floating wind installations.

With more than 70 years of experience in the offshore sector, ABS understands the needs of owners and operators to enhance operational efficiencies with sustainable energy solutions. ABS certified the first semisubmersible offshore wind turbine WindFloat I, classed the world’s largest floating wind turbine Windfloat Atlantic and classed Kincardine, the world’s largest floating offshore windfarm at its commercial online date (COD).