The path to decarbonisation is not straightforward. Shipowners must navigate numerous technological options — cold ironing, hybrid propulsion, energy efficiency upgrades —and decide which offers the best return on investment.

The maritime industry faces an urgent challenge to meet the IMO’s decarbonisation targets: a 40% reduction in carbon intensity by 2030 and net-zero emissions by 2050. For vessel owners, this means retrofitting 50,000 to 70,000 ships. Unlike past retrofits like the Ballast Water Treatment System (BWTS), decarbonisation is far more complex, involving multiple emerging technologies, each at different stages of development and with varying costs and risks.

The path to decarbonization is not straightforward. Shipowners must navigate numerous technological options—cold ironing, hybrid propulsion, energy efficiency upgrades—and decide which offers the best return on investment. The fragmentation of the market, with over 20+ potential solutions, only adds to the confusion, making it difficult to compare options and assess their long-term viability.

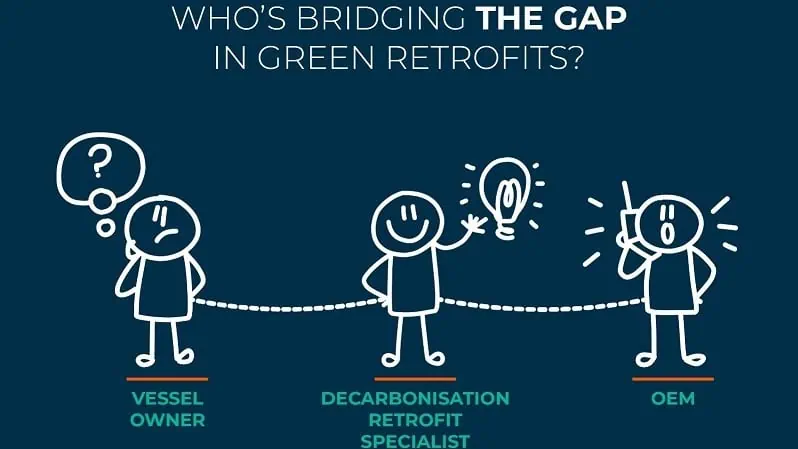

The Role of Retrofit Specialists

Retrofit specialists are becoming essential in this new landscape. These experts offer end-to-end solutions, from initial vessel assessment and technology selection to engineering, project management, and post-installation support. Their role is to guide vessel owners through the entire retrofit process, ensuring seamless integration of new systems while minimising operational downtime.

- Vessel Assessment: Specialists evaluate each vessel’s unique needs, operational profile, and energy efficiency.

- Technology Selection: They match the right technology to the vessel’s specific requirements, considering ROI and compliance.

- Project Management: Specialists coordinate retrofits, working with shipyards, OEMs, and classification societies.

- Post-Retrofit Optimisation: Ongoing monitoring ensures continued performance and regulatory compliance.

Why Specialists Are Critical

Many shipowners, especially those with smaller fleets, lack the resources to keep up with evolving technologies. Without a specialist, they risk delaying decarbonisation decisions, threatening the industry’s ability to meet the IMO’s targets. Additionally, shipyards and OEMs, while critical, often don’t have the full scope needed to manage such complex projects—this is where retrofit specialists provide critical strategic oversight. Delaying retrofits could push the maritime industry past its regulatory deadlines, while also weakening the emerging decarbonisation technology market.

Conclusion

The decarbonisation of the global fleet is achievable but requires expertise. Decarbonisation retrofit specialists are crucial in navigating this complex landscape, providing the knowledge and guidance necessary for a smooth transition. With the right partnerships and strategies, the industry can meet its goals and build a more sustainable future for maritime operations.

At GLO Marine, we are already playing this role. Our skill set and multidisciplinary team are uniquely tailored to meet these demands, offering end-to-end retrofit services that help vessel owners navigate the decarbonisation maze. Having already participated in three significant projects involving decarbonisation solutions—cold ironing, rigid sail installations, and hybridisation—we have hands-on experience with the challenges and intricacies of integrating these advanced technologies

About GLO Marine

GLO Marine’s team consists of experienced professionals with a proven passion for shipbuilding whose ethos is built on honesty, respect and hard work.We put great emphasis on the soft skills that make the difference between a good team and a great one: efficient communication, problem solving, teamwork and self-development.We’re positive, open and honest and our can-do attitude and collaborative mindset make us so agile and dynamic.