More sustainability and increasing digitalization of maritime applications: For shipping companies and ship owners, these two issues are among the key challenges in the next few years. For example, stricter statutory regulations are intended to reduce emissions on the sea and inland waterways worldwide. This means that demand for sustainable propulsion concepts will rise sharply in the next few years. Digitalization also offers the shipping industry a wealth of new opportunities to make vessel operations more efficient and safer. From September 3 to 6, both these topics will take center stage at the Voith Turbo stand at the SMM 2024 in Hamburg, which is the most important gathering for the maritime industry worldwide.

First first electric Voith Schneider Propeller with eight blades

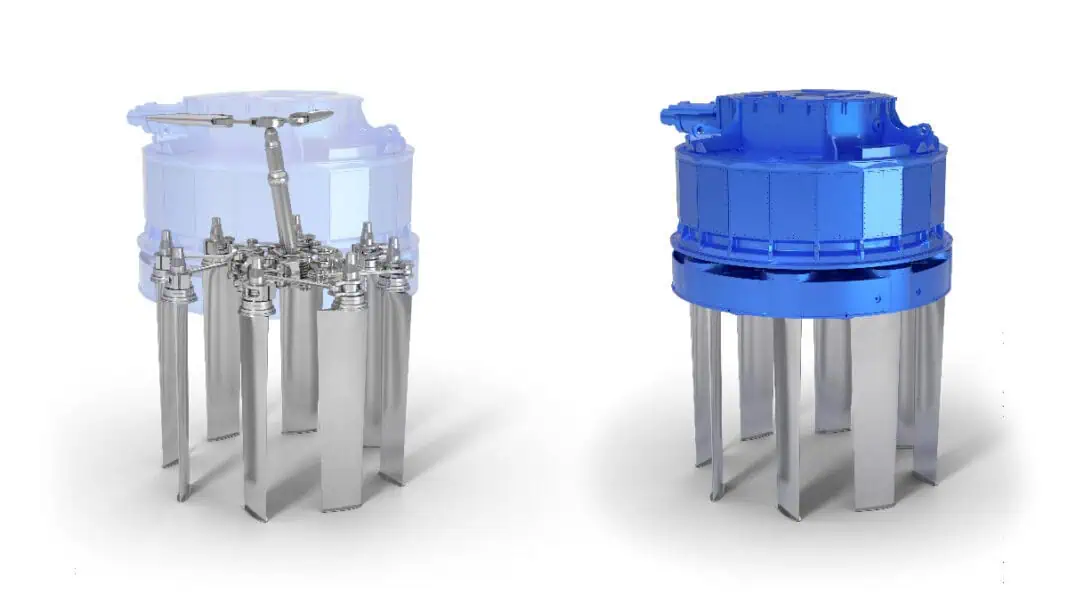

At SMM 2024, the most important gathering for the maritime industry worldwide, Voith Turbo will be showcasing the latest iteration of its sustainable propulsion concept: the first electric Voith Schneider Propeller (eVSP) with eight blades. The eight blades ensure that maritime applications can operate even more quietly. The eight-bladed eVSP reduces the background exposure for marine life due to noise and/or underwater sound, which has almost doubled worldwide in the last few years – partly because of increasing shipping traffic and the engine noise from these vessels. Thanks to this noise reduction, the new eVSP is making an important contribution to protecting marine fauna.

Meteor IV exploits the benefits of the eVSP

The latest iteration of the eVSP will be used for the first time in practice in the Meteor IV – a special-purpose vessel that is being built in Rostock on behalf of the German Federal Ministry of Education and Research. The 125-meter-long ship will carry out multi-functional and interdisciplinary tasks with a focus on environmental and climate issues. To this end, the Meteor IV will be equipped with cutting-edge technology. The vessel will be propelled by an eVSP type 32X8/285 at the stern. It is also fitted with a Voith Inline Thruster (VIT) type 2000-1650H.

Voith Turbo uses a permanent magnet electric motor from its subsidiary ELIN Motoren to drive the eVSP. Thanks to its design principle, the eVSP does not need a gearbox, which enables especially efficient operation and a compact design. This gives ship designers more scope for integrating the drive unit.

Naturally, the eVSP also offers the traditional benefits of VSP technology – like fast acceleration and short response times for precise and safe maneuvering. Moreover, the innovative drive unit impresses with its high efficiency, even in the part-load range, an especially low maintenance requirement, and low pollutant and noise emissions.

Alongside the highlights already mentioned, visitors to the Voith Turbo booth at the SMM can also gain a comprehensive overview of innovations in the company’s product range as well as the latest developments in the digitalization of maritime applications. One such innovation is the rcVSP, for example, a system for the remote control of ship assistance tasks that makes the operation of tugs more efficient and safer. The topic of autonomous driving will also play a role at the SMM. Just recently, Voith Turbo successfully tested in practice a pilot project in the field of inland waterway navigation, where the focus was once again on improving efficiency and safety.