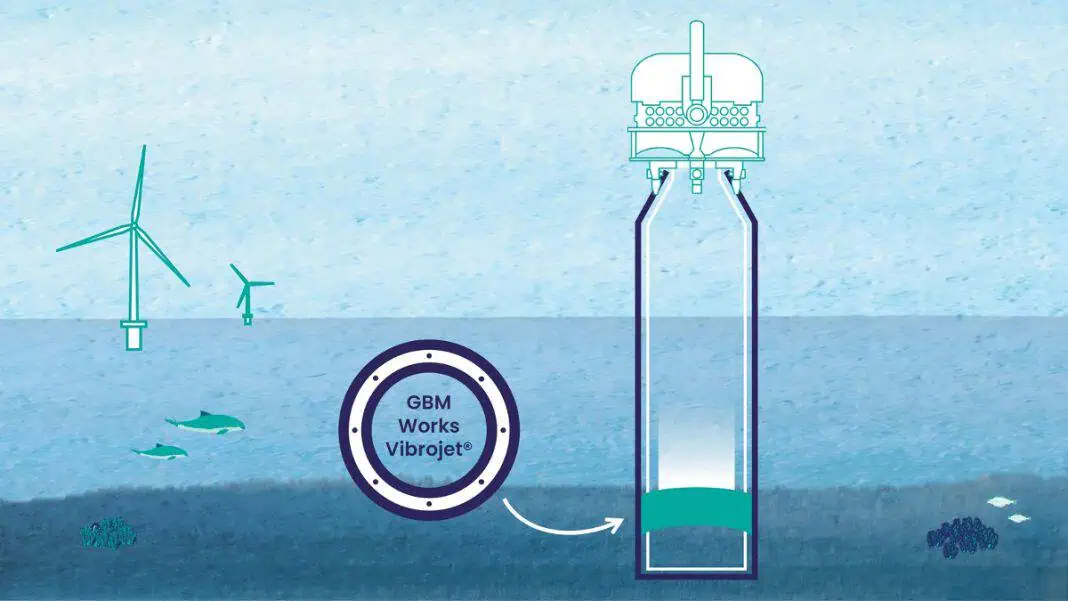

GBM Works and Ecowende have signed a contract for the installation of three monopiles in the Hollandse Kust West (HKW) Site VI offshore windfarm using GBM’s noise reducing technology, the Vibrojet®. This innovative technique is based on the combination of vibrations on the top of the monopile with GBM’s patented jetting technology inside of the monopile. This combination of vibrations and jetting reduces resistance, making the installation more efficient and more silent, minimizing the impact to marine life.

By selecting the Vibrojet® for the demonstration in the selected three locations, Ecowende confirms its position as supporter and front runner of innovative techniques, on its mission to build the most ecological wind farm yet.

Arnold Reijnders, Engineering Manager at Ecowende: “We are enthusiastic to work closely together with GBM to develop their fixed Vibrojet® system for actual use during the construction of our windfarm. We hope we are able to deliver an important contribution in making the next generation offshore windfarms more eco-friendly.”

Ecological and operational benefits

Besides the ecological benefit of being more silent, there are several operational benefits. In comparison to the traditional impact hammer, the Vibrojet® allows monopiles to be installed quicker. In comparison to the Vibro-hammer only, the Vibrojet® allows monopiles to be installed deeper.

Marcelo Werneck, Business Development Director at GBM Works: “Hollandse Kust West represents our entrance to the offshore installation market and we are proud to contribute to Ecowende on its ecological ambitions. By installing the three monopiles, we will prove the value of Vibrojet® installations, an important step towards broader application of the technology on future projects.”

The scope of the contract includes, amongst others, engineering and manufacturing of the jetting system and offshore support during the installations. To execute the project, GBM Works is also working closely with Ecowende’s partners Van Oord, SIF and Ramboll.

SIMPLE III and pioneering sustainable installations

In addition to the contract for HKW, Ecowende is also supporting GBM Works in the development project SIMPLE III, by providing funds and the opportunity to test the technology in HKW. In the scope of SIMPLE III, to be delivered ahead of HKW, the Vibrojet® will be tested in pilot scale offshore and noise measurements will be made to quantify the sustainability benefits. The tests will take the technology to readiness level (TRL) 7.

Marcelo Werneck concludes: “The SIMPLE III project has been designed to allow the Vibrojet® technology to be assessed in an offshore setting closely resembling conditions at HKW, intending to mitigate operational risks during the commercial installations.”.