The Canadian Coast Guard (CCG) has asked for engineering design consultancy services from Griffon Hoverwork to update their current air cushion vehicle (ACV) design and to conduct feasibility studies into alternative power plant options.

The Canadian Coast Guard operates a fleet of four ACVs, which primarily support the CCG’s search & rescue, icebreaking and marine navigation services mandate in the central and western regions of Canada. Due to their aluminium build and icebreaking core duty in harsh environments, the ACVs have a relatively short in-service life expectancy and are ready to be replaced.

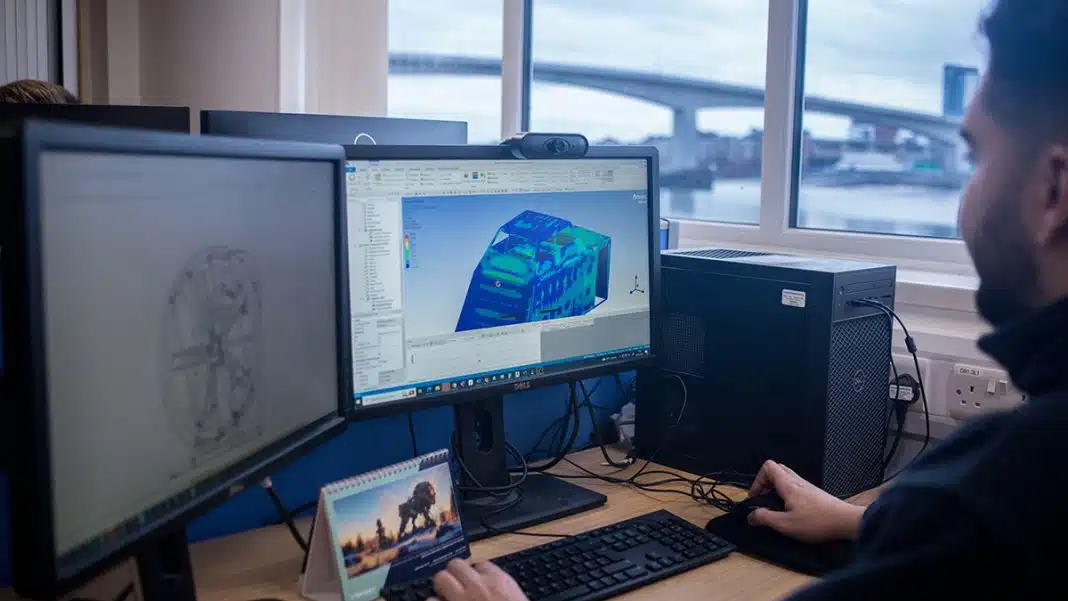

Mark Downer, Engineering Director at Griffon Hoverwork says “Griffon’s experience in ACVs is extensive, with a track record of our products operating in more than 45 countries and a pedigree stretching back seven decades. Over that time we have continually evolved our hovercraft, both in terms of upgrading existing models and introducing new designs.

We have also been working on alternative energy systems since 2014 when we designed a new electric drive system. Subsequently we’ve integrated similar systems into a number of other marine vessel designs and collaborated with leaders in the supply of zero emissions technology to develop 100% battery power and hydrogen powered vessels.

We are delighted to be able to bring this expertise and experience to the next exciting phase of ACV operations for the Canadian Coast Guard.”

The contract requirements are split into several phases, the first of which is a feasibility study to determine the most suitable future fuel for the CCG’s next generation of ACVs to comply with International Maritime Organization (IMO) 2050 Zero emission of greenhouse gases, and to assess the impact this will have on the craft performance, structure and systems in both the short term and long term The results of this feasibility study will determine the direction of further design considerations of a complete craft proposal.

The Canadian Coast Guard stated “Griffon Hoverwork is the only known supplier capable of performing the design work and feasibility studies on the only known compatible ACV design.”