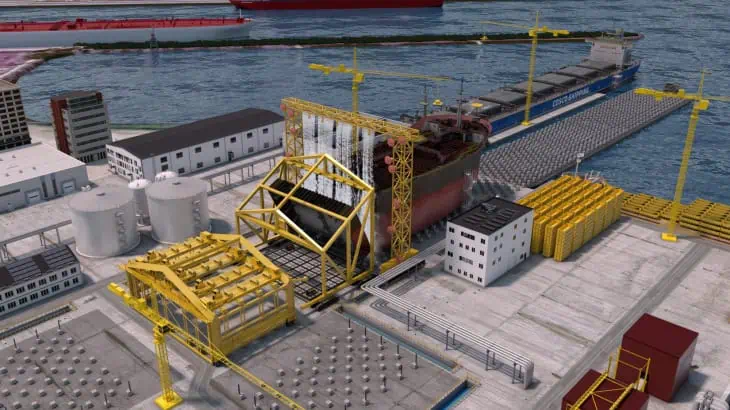

Huisman, in partnership with CMT International, is co-developing pioneering technology for the circular, safe, and competitive dismantling of ships. This innovative approach offers a sustainable alternative to the “beaching” of ships, where they are being scrapped under hazardous and highly polluting conditions.

In the fourth quarter of 2024, Huisman will begin testing the first prototype of a saw designed to cut ships into manageable slices. This saw is the core component of this new technology. Huisman’s commitment to developing cutting-edge solutions that advance the circular economy and enhance worker safety is a key part of its overall vision.

By automating and speeding up the dismantling process, while reducing the reliance on manual labour, the system becomes more circular, safer, and highly competitive. This allows for the efficient recovery of high-quality steel scrap from ships, meeting stringent European recycling standards. In addition, CMT International’s solution contributes to sustainable steel production by supplying clean, high-grade scrap steel — a vital resource.

In the coming years, a significant number of seafaring vessels will need to be dismantled. This includes large cargo ships built during the economic boom of the 2000s, which are now approaching the end of their service life. However, there is a shortage of shipyards that comply with international environmental and safety regulations required for sustainable and safe ship recycling.

The development of this new ship dismantling technology is supported by key investors, including the Sojitz Group and Jansen Recycling, with additional funding from the EU’s “Opportunities for West” grant programme.