At first glance, the Mannheim appears to be a typical 200-metre-long inland cargo vessel. However, beneath its conventional exterior lies a groundbreaking innovation in maritime engineering. The vessel’s advanced engine room features a high-tech diesel-electric powertrain, powered by five high-performance PACCAR MX-13 engines supplied by DAF Components, marking a significant leap forward in sustainable and efficient inland shipping.

Thanks in part to the formidable 530 hp PACCAR MX-13 engines built by DAF in Eindhoven, the Mannheim is 30% more efficient. The ship’s NOx emissions are also five times lower when compared with similar vessels equipped with a conventional powertrain. In addition, the diesel-electric installation makes the 4,600-tonnes Mannheim much quieter and more comfortable. The ship will be used by Rhenus Partnership – a subsidiary of the German logistics specialist Rhenus Group – for transport between Southern Germany, Antwerp and Rotterdam.

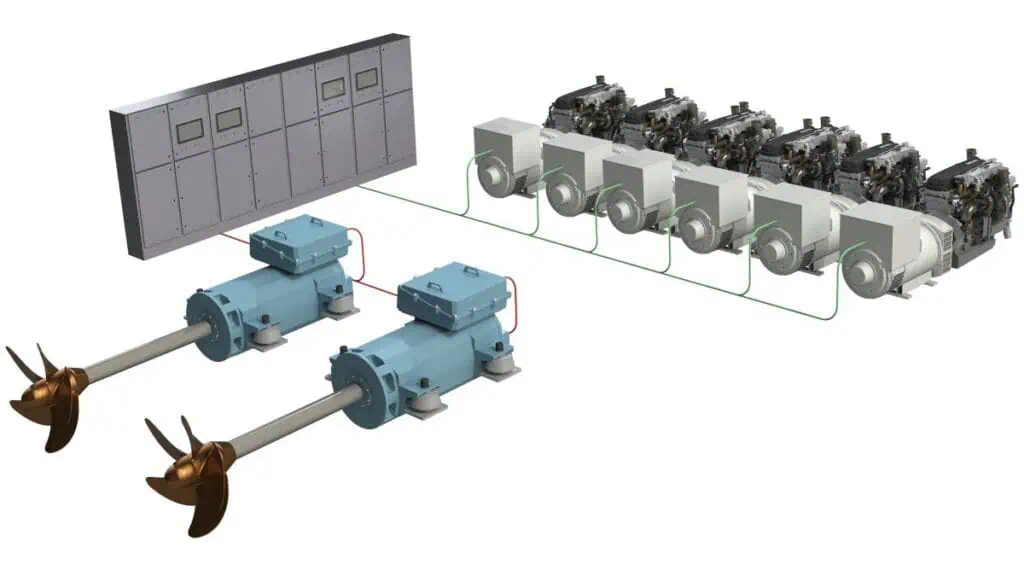

The idea of using a diesel-electric powertrain first came from Rhenus. They approached Vink Diesel, a family firm based in Sliedrecht (NL), and asked them to fit out the Mannheim with a powertrain driven by five PACCAR MX-13 engines. Each of the five modularly connected engines, supplied by NPS Driven, drives a generator that powers two electric motors and, ultimately, the ship’s two propellors.

The powertrain offers a maximum horsepower of 2650 hp (1946 kW). An innovative power management system controls the number of MX-13 engines that need to be running and at what capacity. When the Mannheim is transporting a full load upstream, all five of the engines are used to generate the maximum amount of electricity. And when sailing downstream, one engine is often enough. This flexibility delivers significant savings on fuel and a major reduction in CO2 emissions.

An extra battery and an additional hydrogen-powered energy source even make it possible to shut down the engines temporarily so that the ship can be manoeuvred fully electrically – and emission-free – when in port. The inland cargo vessel Mannheim can also sail with zero emissions when passing through towns and cities located on the river.

“This solution offer major benefits,” says Peter van der Heijden, director of NPS Driven. “The efficiency of the PACCAR MX-13 engines is unparalleled and they only run when needed. Compared with similar conventional powertrains, the fuel consumption and CO2 emissions are a full 30% lower. And the fact that Rhenus has chosen HVO as their fuel means that CO2 emissions are reduced by a further 90%. The NOx emissions of the PACCAR MX-13 engines are also five times lower than the cleanest marine engines currently on the market.”

“For a powertrain as revolutionary as this one, we wanted to find the most efficient and cleanest energy source on the market. DAF Components, PACCAR MX-13 engine was the best option on all fronts,” according to Robert Graf-Potthoff, technical inspector at Rhenus. “The fact that the PACCAR MX-13 engines require far less maintenance than a standard marine engine significantly increases the ship’s availability.”