MAN Engines is consistently pushing ahead with the development of future technologies. The latest coup from the engine manufacturer, which is a business unit of commercial vehicle manufacturer MAN Truck & Bus, is a stationary combustion engine powered by hydrogen (H2). As part of combined heat and power (CHP), this converts the energy from the fuel – in this case hydrogen – into electricity and usable heat. This combined generation of electricity and heat in one plant is summarized under the collective term combined heat and power (CHP) and achieves overall efficiencies of approx. 90 percent. Test operation on the engine test bench at MAN’s Engine Competence Center in Nuremberg, Germany started at the beginning of May with the usual routine.

“We are building on a wealth of experience in both stationary combustion engines for CHP applications and hydrogen. That is why we are confident that we will certainly achieve our targets in terms of performance and efficiency with the new hydrogen engine as well,” says Werner Kübler, Head of Engineering at MAN Engines.

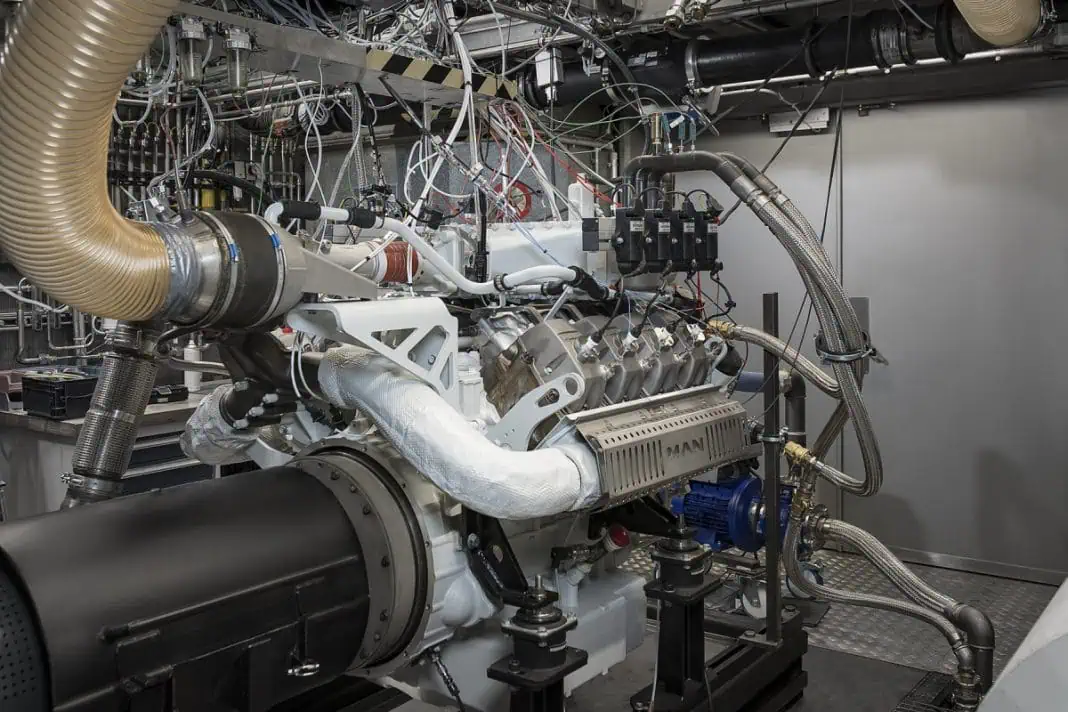

The hydrogen engine on the test bench is an eight-cylinder MAN H3268 V-engine with a bore of 132 mm and a stroke of 157 mm. As a stationary engine for combined heat and power generation, it is the first test bench variant to be operated at a constant speed of 1,500 rpm at 50 Hz, which is primarily intended for Eurasian target markets. In general, there are numerous parallels between the MAN E3268 V8 natural gas engine presented at Agritechnica ten years ago and the new MAN H3268. Both combustion engines are based on the same basic engine, which has been used in many thousands of natural gas and special gas engines for years. Among other things, the turbocharging, the injectors and the mixture preparation will be adapted for operation with hydrogen.

“Thanks to the similar geometry and identical connections of our future hydrogen engines, we can already offer our customers products that are H2-ready. In this way, we are simplifying the conversion of existing plants from operation with natural gas to hydrogen,” says Jürgen Haberland, Head of Power MAN Engines.

In terms of performance, the development goal of the MAN H3268 is also based on the size of the MAN E3268 natural gas engine, which offers 370 kWmech. MAN Engines is thus continuing to consistently pursue its philosophy of high power density, i.e. providing high performance in a compact installation space. “We are aiming for a similar performance class for the hydrogen engine as for our natural gas engine. In principle, we are improving our existing natural gas engine by redesigning it into a hydrogen engine. Powered by green hydrogen, it produces electricity and heat with high efficiencies in a 100% CO2-neutral manner,” says Head of Development Kübler.

MAN Engines currently offers gas engines for power and heat generation with four, six, eight and twelve cylinders from 50 to 735 kW for power and heat generation. “With the V8, we have deliberately chosen the middle of our service portfolio in order to be able to scale up and down a possible portfolio of stationary hydrogen engines from the center in a balanced manner.” Haberland explains. While MAN Truck & Bus’ Group strategy focuses on battery-electric drives for commercial vehicles, hydrogen represents a possible solution for a wide range of applications at the MAN Engines business unit: The twelve-cylinder MAN D2862 V-engine has been in use as a hydrogen dual-fuel engine on a wind farm supply ship for over a year. As a pure hydrogen combustion engine, the MAN H4576 in-line six-cylinder engine is being modified for off-road applications and is already planned as a possible, CO2-neutral drive option for Kässbohrer’s PistenBully 800. The MAN H4576 is a transfer of know-how from the “Bavarian Fleet” research project, in which a comparable hydrogen engine for trucks is being tested on the road.