For the first time, MAN Engines is presenting possible ways for sustainable propulsion systems as well as solutions for stationary energy storage. “Our goal is to transform our portfolio so that we offer our customers solutions in agricultural and construction technology, for watercraft and in power generation that do not release CO2 locally. Our ambition – today and in the future – is to use our products and services to simplify the business of large and small OEMs towards decarbonisation,” says Mikael Lindner, Head of MAN Engines. The path to the future is clearly defined at the parent company MAN Truck & Bus: “MAN is accelerating its transformation and taking big steps towards emission-free drives. The focus at MAN Truck & Bus and the TRATON Group is clearly on battery-electric drives,” says Alexander Vlaskamp, Chairman of the Executive Board of MAN Truck & Bus SE. “Recently, however, we have also stepped up our R&D efforts in the hydrogen sector and built a truck prototype with a hydrogen-based combustion engine for future niche applications and for off-road propulsion, for example, or at sea,” says Vlaskamp.

As a business unit, MAN Engines is clearly also following this path and draws on this in-house knowledge, decades of industry and service experience, but also external know-how from experienced partners in the development of future technologies. MAN Engines’ customers come from very heterogeneous industries with different requirements for the drives, different availability of fuels and different available installation space for energy storage systems. In the medium and long term, a wide range of drive concepts will therefore be available. “In the future, MAN Engines will rely on pure combustion engines for hydrogen and regenerative fuels, battery storage systems and also complete electric drive systems to operate vehicles and machines locally with the lowest CO2 emissions to meet the various requirements,” explains Mikael Lindner.

MAN Engines already offers a wide range of products that take into account the requirements of the industry and at the same time take advantage of opportunities to reduce CO2 emissions. “We have already presented and are also using solutions that contribute to decarbonization. We see the bridging technologies available today as an opportunity for the energy transition that takes into account the framework conditions of the market,” says Lindner. These available technologies include stationary biogas engines, hybrid and dual-fuel engines, and the release of engines for the use of renewable and alternative fuels.

MAN Engines envisions the following technologies in its portfolio in the short, medium or long term to support customers in decarbonizing their products:

Battery storage and integrated e-drive systems:

At the IAA Transportation 2022, MAN Truck & Bus presented the near-production prototype of the new MAN eTruck, which will make its market debut from 2024, to a large international audience for the first time. With a daily range of up to 800 kilometers and megawatt charging capability, the new eTruck will not only electrify long-distance transport, but also all common transport areas covered by diesel trucks today. In 2024, the first heavy-duty eTrucks of series production will roll off the assembly line in Munich and onto the yard of the first customers. Today, more than 3,000 MAN Lion’s City E electric buses and MAN TGE vans are already on the road. In addition to MAN Truck & Bus’s electrical expertise, there are several million kilometres of the MAN eTGM medium-duty distribution truck, which this small-scale electric vehicle has “experienced” with a total of 60 customers since 2019.

For the batteries of the electric vehicles, almost 100 million euros will be invested in this important future technology at the MAN plant in Nuremberg, among other places. Here, battery packs are to be manufactured in in-house large-scale production. The capacities of the plants in Munich and Nuremberg are coordinated for this purpose.

In addition to their use in the Group’s own vehicles, these batteries will also be available to OEM manufacturers of agricultural and construction machinery as well as watercraft in the future. In the area of electricity storage, in addition to the use of new products (1st Life), the secondary use of batteries (2nd Life) also comes into play. MAN Engines already offers its B2B customers tailor-made drive solutions for market-leading solutions and thus often significant added value for end customers. In the medium and long term, diesel and gas engines will not only be pure battery packs, but also the appropriate software in addition to the hardware. This will come from a single source, as will the engineering know-how, high-quality series production and just-in-time delivery. This application-specific expertise, bundled with hardware and software expertise in battery technology, will make it possible to develop fully integrated drive systems together with machine manufacturers in the future.

Hydrogen internal combustion engine:

Such drive solutions can be a supplement or alternative to battery-electric drives in applications with high flexibility requirements. At MAN, the hydrogen combustion engine is one of the most conceivable mobility solutions in various applications, for example in the maritime or off-road sectors, but also in the stationary sector for combined heat and power.

In the first step, a truck prototype has therefore already been equipped with a hydrogen combustion engine. It has been in testing since the end of 2021. At the heart of the demo truck is a 16.8 L hydrogen engine with approx. 500 hp and 2500 Nm based on the diesel engine kit. The expected service life is comparable to conventional combustion engines, even when using low-grade hydrogen. Thanks to the use of dual-flow cooled exhaust gas recirculation and a simplified SCR exhaust gas aftertreatment system, the prototype truck with the hydrogen combustion engine was recently approved as a ZEV (Zero-Emission Vehicle).

For the off-road sector, MAN Engines presented the prototype of a possible hydrogen combustion engine for a snow groomer at the Interalpin in Innsbruck in mid-April 2023: The vehicle concept of the PistenBully 800 from Kässbohrer Geländefahrzeug AG already takes into account the fact that there is room for a future hydrogen combustion engine – the MAN H4576 – and that corresponding interfaces are available. As a result of these preparations, the hydrogen engine should be able to replace the diesel engine in the PistenBully 800 in due course. The MAN H4576 is based on the basic engine of the MAN D3876 diesel engine and uses about 80% common parts. The assemblies for hydrogen supply and combustion, engine control and exhaust gas regulation are subject to significant adaptation and changes.

In addition, MAN Engines has been testing a stationary combustion engine powered by hydrogen (H2) on the test bench since the beginning of May 2023. As part of combined heat and power (CHP), this converts the energy from the fuel – in this case hydrogen – into electricity and usable heat. The hydrogen engine on the test bench is an eight-cylinder MAN H3268 V-engine with a bore of 132 mm and a stroke of 157 mm. A similar geometry and identical connections of the future hydrogen engines are also intended to make it easier for customers to convert existing plants from operation with natural gas to hydrogen. “Hydrogen combustion engines are a possible way to advance the decarbonization of drives in off-road vehicles or even combined heat and power. When the market is ready, MAN Engines will offer the right solutions,” says Mikael Lindner, Head of MAN Engines.

Hybrid systems:

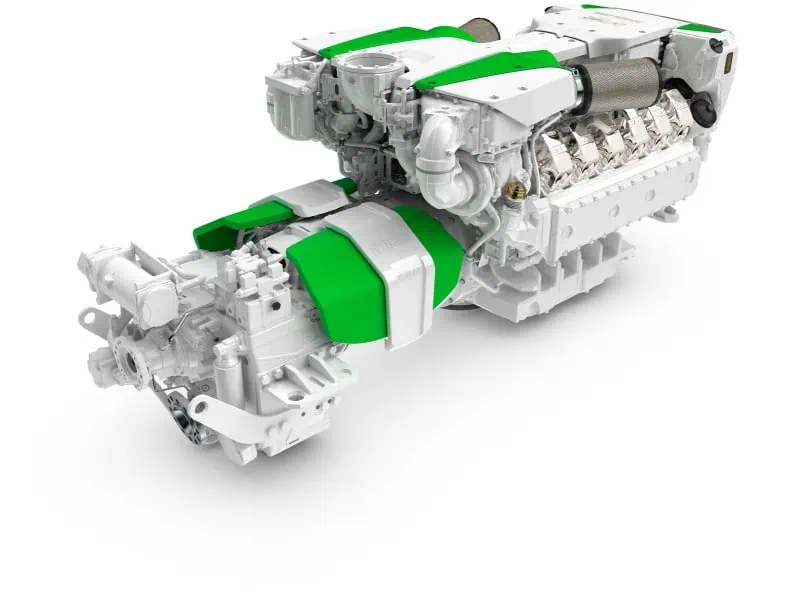

With the MAN Smart HYBRID Experience, MAN Engines is the first engine supplier to offer a complete hybrid system for ships from a single source: MAN Engines accompanies shipyards and ship designers from the planning and concept phase through development, installation consulting and technical implementation, including control software, to service and maintenance. The MAN Smart HYBRID Experience was presented for the first time in 2021 for yacht applications. Because it can be combined with all MAN marine engines of the current D2862 (V12), D2868 (V8) and D2676 (R6) series, engines for light, medium and heavy applications in commercial shipping can be expanded in terms of performance.

This means that total system outputs per powertrain from 147 kW to 1,985 kW (200 hp to 2,700 hp) can be achieved and hybridization levels of up to 71 percent of the total output can be achieved. The high-voltage battery of the plug-in hybrid system is charged via the integrated shore connection or by the diesel engines or on-board units while driving. The MAN Smart HYBRID Experience enables driving and anchoring without any emissions in battery-electric mode.

Hydrogen dual-fuel engine:

The world’s first hydrogen-powered crew transfer vessel for offshore wind farms was launched on May 10, 2022. What’s special about it is that the “Hydrocat 48” from the Dutch shipyard Windcat Workboats uses two tried-and-tested MAN D2862 V12 marine engines, each with 749 kW (1,019 hp), which are usually powered by hydrogen. They were prepared by MAN Engines for dual-fuel operation, i.e. for the use of two different types of fuel, and by development partner CMB. TECH supplemented with a hydrogen injection system. The use of hydrogen reduces CO2 emissions in the exhaust gas by an average of about 50% and even up to 80% as a peak value. In addition, pure diesel operation, for example when hydrogen supplies are exhausted, will continue to be possible without interruption. This ensures operational safety at sea at all times. An SCR exhaust aftertreatment system also reduces the emission of nitrogen oxides (NOx) in the exhaust gas in accordance with the latest regulations of the International Maritime Organization (IMO).

Hydrogen admixture in the fuel of gas engines

Since mid-2021, stationary gas engines of the types MAN E3262 LE202 (turbocharged lean-burn engine) and MAN E3262 E302 (naturally aspirated lambda-1) have been designed by MAN Engines for the admixture of up to 20% hydrogen (H2) by volume when operated with natural gas. In this way, MAN Engines is supporting operators in designing their CHP plants for “hydrogen readiness” plants, the promotion of which is currently being examined by the German government via the CHP Act.

For operation with hydrogen-containing fuels with up to 20% hydrogen admixture by volume, no design changes to either engine type are necessary for the MAN V12 natural gas engines. This means that the “hydrogen readiness” of up to 20% by volume applies to all engines of the types mentioned in existing systems (with knock detection) as well as to new deliveries. With an admixture of 20% hydrogen by volume, the Lambda-1 engine E3262 E302 achieves CO2 savings of 5.7% and an HC reduction of 23.0%. The turbocharged lean-burn engine E3262 LE202 achieves CO2 savings of 11.2% and a HC reduction of 17.4%. In addition, an increase in efficiency of 1.2 percentage points is achieved here. Thanks to the high number of more than 22,000 MAN gas engines installed in existing combined heat and power plants (CHP), around four million tonnes of CO2 are saved worldwide every year. This substitution results from the highly efficient power and heat generation of gas engines in CHP plants instead of energy generation by conventional technologies. The addition of as little as 1% by volume of hydrogen, which burns CO2-neutrally, also contributes to the avoidance of approx. 100,000 tonnes of local CO2 emissions.

Regenerative diesel/HVO:

In June 2022, MAN Engines had already approved all marine engines from its current product portfolio for use with regenerative diesel in accordance with the EN15940 standard in Europe and the US specification ASTM D975 of the American Society for Testing and Materials (ASTM). All engines from the off-road sector (agricultural machinery, railway, construction and industrial applications) recently followed in May 2023. Customers can use it to replace conventional petroleum-based diesel fuel and use so-called green or regenerative diesel instead. This is obtained on the basis of waste and residues of animal and plant origin, cellulosic biomass materials such as crop residues, but also so-called HVO (Hydrated Vegetable Oils). Regenerative diesel ensures clean combustion with fewer emissions, as the combustion of renewable diesel emits approx. 30% less particulate matter and approx. 10% less nitrogen oxides (NOx). Nevertheless, there are neither performance losses nor disadvantages in terms of service and maintenance intervals for the engines.

Customer Service:

In addition to MAN Engines products, the international network of service companies and partners also plays a key role on the way to decarbonisation. More than 1,650 service outlets worldwide ensure short travel distances and support customers in keeping their products up and running and up to date. In general, regular maintenance contributes to cleaner combustion and reduces the risk of increased fuel consumption.

MAN Engines offers an opportunity to conserve resources through the sustainable remanufacturing of used parts such as coolant pumps, flywheels or cylinder heads as part of the MAN Genuine Parts ecoline product line. However, complete engines are also remanufactured in a separate business unit of MAN Truck & Bus. In this process, valuable parts such as crankcases or crankshafts are made fit for a “second life”. Other wear parts such as seals or bearings are always replaced as part of the repair. Under the name MAN Genuine Factory Repair, these engines are sold to customers worldwide. In addition to cost savings, an original engine remanufactured by MAN conserves important resources by reusing old parts. Added to this is the energy saved – and thus also CO2 – through reprocessing instead of new production.