Dutch maritime research institute MARIN this week tested three innovative barriers aimed at averting collisions between ships and wind turbines. The research was prompted by the incident involving the Julietta D on 31 January this year. This drifting bulk carrier initially collided with a tanker before hitting a transformer platform and a turbine foundation for the Hollandse Kust Zuid windfarm currently under construction. A collision with an installed wind turbine carries a real risk of the turbine toppling onto the vessel, seriously endangering crew, passengers, the ship itself and the environment.

URGENCY

Some 2500 wind turbines are set to be installed on the North Sea in the period to 2030, taking the risk of a turbine being hit by a ship to around 1.5 to 2.5 times a year, research1 by the Maritime Research Institute Netherlands (MARIN) for the Dutch government shows. To give an idea: vessels going adrift on the North Sea number around eighty each year. Accidents can be avoided in various ways: drifting vessels can put down their anchors, for example. But this requires active intervention by the ship’s crew in often difficult circumstances. Alternatively, emergency towing vessels (ETVs) can be deployed to tow the drifting ship to safety, while shipping supervision can be upgraded to include some form of vessel traffic management2. ‘The accident involving the Julietta D shows the real dangers posed by vessels adrift,’ says MARIN’s Traffic & Safety team leader Yvonne Koldenhof. ‘Even with current resources such as ETVs, it’s difficult to avoid these kinds of incidents.’

‘CRASH BARRIERS AT SEA’

A group of 20 experts from MARIN and the wider maritime sector developed a trio of innovative concepts for maritime crash barriers between shipping routes and windfarms during a February 23 workshop. ‘Our mission statement includes both marine safety and sustainable sea use,’ explains MARIN’s general director Bas Buchner. ‘That means more than simply drawing attention to the dangers; it means going in search of solutions to prevent accidents. We were keen to do this in tandem with experts from the offshore sector and that’s why we opted for an open innovation project. We gave it the working title “crash barriers at sea” because many wind farms are planned near traffic separation schemes: the freeways of the sea.’

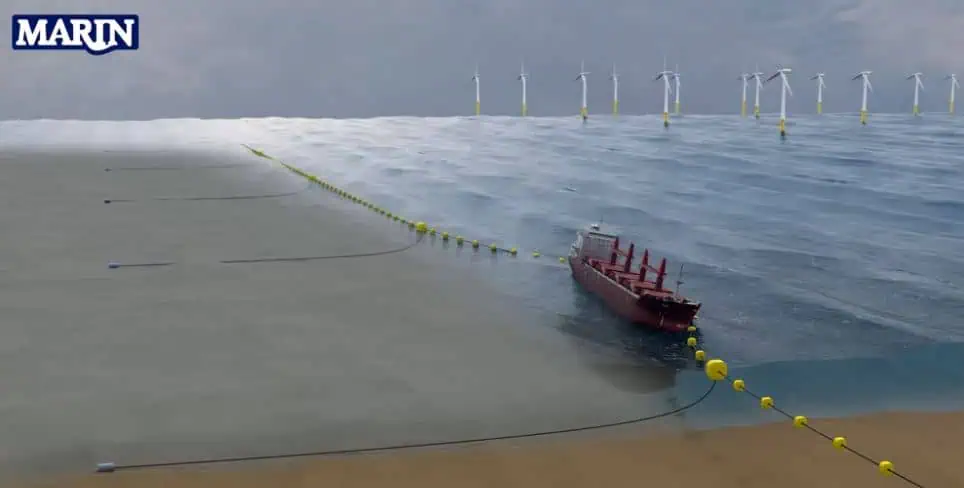

The first concept involves a string of surface buoys secured by drag anchors. The second concept comprises a smart suspension net between fixed poles and the third is an anchored underwater hook line designed to catch the anchor of the drifting vessel. MARIN built scale models of all three solutions and ran tests in its Offshore Basin on 17 and 18 March to see if the barriers were capable of deflecting a scale model comparable to the Julietta D in storm conditions.

The three concepts: a string of surface buoys secured by drag anchors, a smart suspension net between fixed poles and an anchored underwater hook line designed to catch the anchor of the drifting vessel. All concepts were tested in the Offshore Bassin to see if the barriers were capable of deflecting a scale model comparable to the Julietta D in storm conditions.

The first results are promising. ‘We’ve established that all three concepts are able to intercept the vessel,’ says William Otto, MARIN’s Offshore project manager. ‘The drag anchors of the buoy string dissipate the drift energy evenly, so that the vessel stays afloat across the waves. The anchored underwater hook heads the vessel into the waves, so reducing roll. That means the vessel remains in place while being exposed to relatively low forces. The smart suspension net initially showed too much droop, but with a bit of fine-tuning we were able to get this functioning too. Over the coming months we will go on to assess the various pros and cons of these systems.’

The various concepts and all test results are being shared as an open innovation project to enable further development of the most promising concepts. The initiative has also sparked widespread international interest.

Representatives of the following Dutch maritime and offshore organizations were involved in this project: Bluewater Energy Services, Mooreast, Vuyk Engineering, Heerema Marine Contractors, Boskalis, GustoMSC, KRVE (Rotterdam Boatmen), Pinkster Marine Hydrodynamics, Huisman Equipment, Orca Offshore en SBM Offshore.