Pherousa has been granted Approvals in Principle (AiP) from American Bureau of Shipping (ABS) and DNV for its groundbreaking Ammonia Cracking technology. The AiPs, awarded on an independent evaluation basis, confirm the viability and safety of Pherousa’s technology for onboard applications, including integration with Proton Exchange Membrane (PEM) Fuel Cells and Fuel Gas Supply Systems (FGSS) to enable fully electrical propulsion for ships.

Pherousa is together with partners developing Ammonia Cracking technology that could make the transition to fossil-free and zero-emission propulsion within the maritime short- to deep-sea transport sectors a reality. Unlike conventional fuels, ammonia is a non-explosive liquid that carries a significant amount of clean hydrogen energy that, if technology is developed to utilize the contained hydrogen, can be used to drive new types of engines onboard. Therefore, ammonia is increasingly becoming the go-to choice and Pherousa’s technology has potential to provide the solution for enabling the shift to carbon-free maritime transportation.

This milestone achievement marks a significant step forward in the development of sustainable emission-free propulsion solutions for the maritime industry.

Key partners in the work towards the two AiPs include the designers Deltamarin, the flag state Marshall Islands, Babcock International Group, which supplies the FGSS, as well as Metacon, the technology developer and shareholder of Pherousa.

“The Approval in Principle from two of the leading classification societies and certification bodies, ABS and DNV, marks another important milestone for us in the development of zero-emission solutions for the maritime industry. By granting Pherousa these AiPs, both ABS and DNV clearly state that there are no showstoppers of the Pherousa technology for marine application.

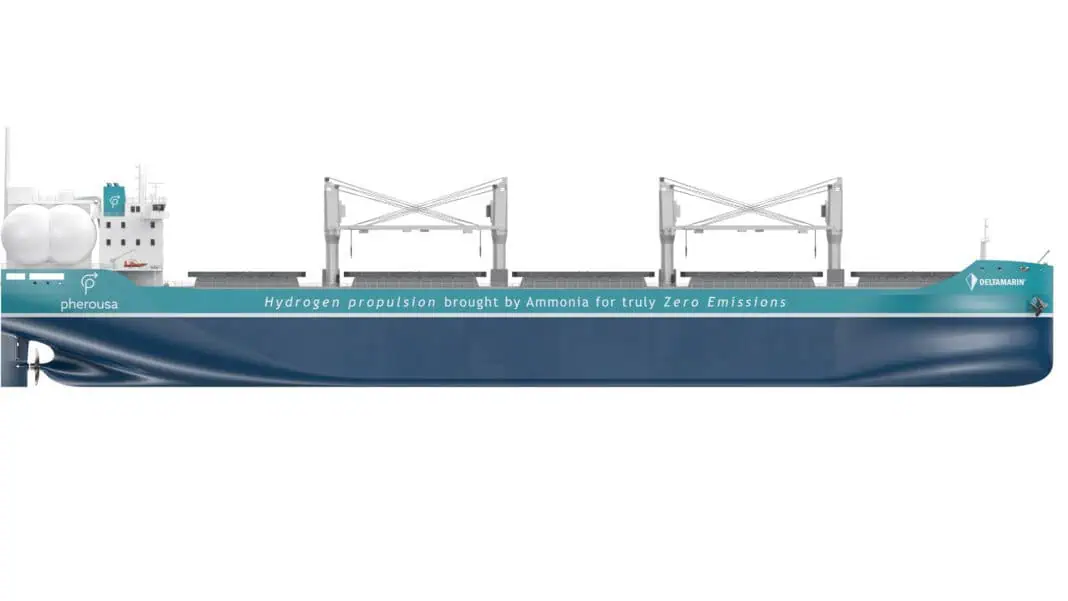

The grants further allow us to continue the design and construction of our series of 64.000 dwt Bulk Carriers earmarked for the Copper industry, to ensure that this specific commodity, so essential to the global decarbonisation, can be delivered across oceans without any carbon footprint at all. Only ships that have no carbon fuels onboard can ensure the end-users that the copper utilized for solar panels or electric cars is free of emissions in its supply chain”, said Hans Bredrup, Chairman of Pherousa AS.

Ammonia is gaining momentum as a hydrogen carrier for technology application onboard vessels, from coastal to deep-sea shipping and in parallel with this development, Clean Ammonia could potentially make up about 13% of the global ammonia supply by 2030.

The Pherousa subsidiary, Pherousa Shipping, has worked closely with two major copper miners during the design process of the Ultramax 64.000 dwt vessel, to find the optimal layout for an emission free transportation of copper concentrates between its origin and the smelters. The vessels are intended to be on water in parallel with the new IMO regulative that comes into force in 2030, thus allowing the cargo industry to use fully emission free vessels for their transportation of goods at sea.

The patented Ammonia Cracking HIWAR® concept by Metacon is a technology designed to efficiently convert ammonia into high-quality hydrogen fuel. By its exclusive license agreement to Pherousa, for use directly on-board ships, it represents a significant leap forward in sustainable maritime energy, paving the way for a cleaner, greener future in the industry. Our approach to Ammonia Cracking is based on thorough research, testing and innovation to ensure optimal performance and reliability for our customers.

The Pherousa Ammonia Cracking can be applied to a variety of developed technologies, such as; supplying Hydrogen to PEM Fuel Cells, replacing conventional fuels with Hydrogen as pilot fuel on Ammonia fueled Internal Combustion Engines (ICE), supplying Hydrogen Internal Combustion Engines (ICE), all yielding 100% emission free propulsion, as well as supplying Hydrogen to Auxiliary Engines to reduce the emissions. Any of the four alternatives can be fitted onboard any type of vessel and with an engine power up to 15-20 MW.

Commodity players can thus obtain emission free transportation with a variety of emission free technologies to select from, working with ship owners / operators to select the technology of choice that suits a particular trade or type of vessel. This adaptability is reshaping the operational efficiency of vessels across the deep blue.

Embracing our ammonia cracker technology is a decisive step toward achieving a carbon-free propulsion system, facilitating a seamless transition from ammonia to hydrogen on-board ships, aligning perfectly with evolving environmental standards and the growing trend of eco-conscious practices in commerce. It’s an ideal solution for those looking to lead in sustainable maritime advancement.

The prototype developed by Pherousa and its shareholders Metacon, has not only been delivered but has demonstrated its practical potential. Pherousa is now transitioning from concept to scale-up and market entry, ready to deploy our innovation on a global scale.

Stergios Stamopoulos, ABS Director, Global Sustainability, says: “Ammonia will have a key role to play in the energy transition at sea, whether as a carrier of hydrogen or as a fuel in its own right. The efficiency of ammonia cracking will play a decisive factor in its ability to contribute to decarbonization of the industry. ABS is proud to play a role in supporting development of this capability.”

Morten Løvstad, VP and Global Business Director for Bulk Carriers in DNV, says: “The future fuel mix for shipping will vary depending on ship type and trade, but green ammonia as a zero emissions fuel is likely to play an important role in this fuel mix. DNV has already provided Class approval for the first ammonia-fueled vessel on water, the Fortescue Green Pioneer, and is now taking further steps together with Pherousa and it’s technology partners to find innovative solutions for truly zero emission solutions for an Ultramax bulk carrier. Ammonia cracking combined with a PEM Fuel Cell has no need for pilot fuel or other fossil sources, and is as such an innovative solution for maritime application towards full decarbonization”

David Wamsley, Deputy Commissioner of Maritime Affairs, says: “The Republic of the Marshall Islands (RMI) Maritime Administrator (the “Administrator”) actively participated in the hazard identification (HAZID) meetings regarding this innovative technology. Given the rapid regulatory changes taking place, development of these types of innovative solutions are critical for advancement of the industry. The Administrator appreciates the opportunity to be part of this project and looks forward to continued participation.” The RMI Registry is one of the leading registries in the world reaching nearly 200 million gross tons and more than 5,700 vessels including bulk carriers, container ships, gas carriers, general cargo, tankers, passenger ships, offshore units, and yachts.”

Christer Wikner, CEO and President of Metacon, says: “I’m happy to see that the ammonia cracking technology developed for Pherousa and now exclusively commercialized through Pherousa has passed such a critical milestone and approval from two of the world’s largest and most powerful classification societies. This technology holds future potential to provide emission-free propulsion to virtually all of the world’s shipping industry.”