Should you specify 3D printed patterns for your sterngear? The answer is yes if you want highly accurate parts or you need a replica fast. We have trailblazed 3D printing in the marine propulsion industry by investing in BigRep GmbH – Large-Scale 3D Printers as part of our automated approach.

Using 3D printed patterns modernises and simplifies the first phases of sand casting, particularly when producing complex geometries. For our customers, that means valuable time in the manufacturing process is saved.

The first step is to design and print the pattern. For reverse engineering projects, it is also possible to scan existing components to create the 3D model. That means we can make highly accurate replicas so our customers can be confident their new sterngear matches the originals.

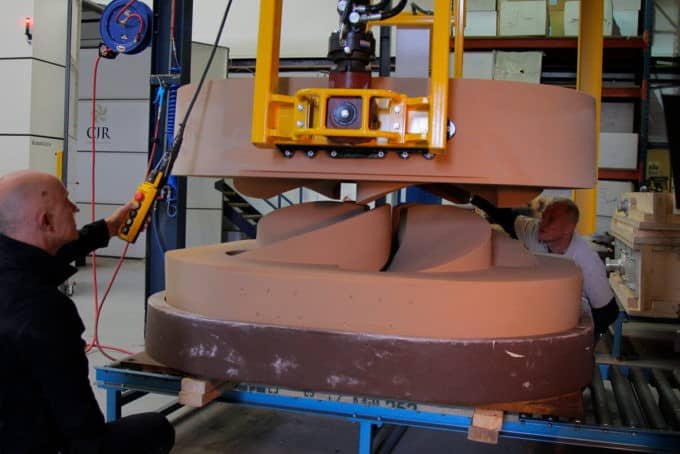

If the object to be sand casted is larger than the print volume then it can be printed in parts and assembled after. The remaining steps are standard sanding casting processes. The printed pattern is then packed with sand and removed from the mould. Molten metal is poured into the mould cavity and the final part can be polished and post-processed as needed.

To see how we use 3D printers, watch the video below,