As equipment increases in complexity, there is a growing need and advantage to being able to monitor parts of, or a complete system remotely.

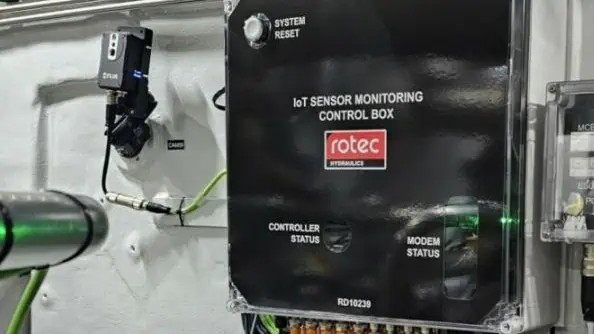

With a long held commitment to innovation, Rotec Hydraulics are the first known company in the UK to have designed, installed and commissioned Parker IoT software that remotely monitors a hydraulic system.

With the ability to be installed and remotely monitor any hydraulic system, Parker Internet of Things (IoT) technology allows a user to ensure their assets are working at full functionality by monitoring key performance indicators, such as temperature, pressure and flow.

The remote monitoring technology further benefits the user by providing vital performance feedback for preventative maintenance planning, and can monitor real time and historical data all within a simple web-based interface.

This web-based portal can be accessed worldwide and gives a further benefit of GPS asset tracking and visibility – thus aiding both security of equipment and logistical transport efficiency which in turn, can reduce fuel costs.

The innovative IoT project came to fruition following Rotec being asked by a boat manufacturer to gather information about the performance of the hydraulic system they were fitting to a new fleet of vessels.

Because of the harsh marine environment, robust equipment was selected that meets high ingress protection. IoT modems are compact and have built in aerials allowing for a sealed solution, meeting strict IP67 ingress protection and wide temperature ranges of -30 to +75 degrees.

Multiple sensors were fitted by Rotec’s engineers to provide feedback of tank levels, oil temperatures, flows and pressures in various parts of the system.

A further enhancement was provided by adding a particle contamination device which monitors and uploads the vessel’s oil cleanliness data to the cloud. Previously hydraulic oil changes were performed on a time expiry basis, whereas adding sophistication of a real time oil contamination device now tells the customer when the oil needs to be changed rather than changing at estimated time intervals. This reduces both the cost for the customer and decreases the impact on the environment because they are now performed only when required.

The customer was particularly impressed as Rotec Hydraulics were able to code unique software and download this remotely to assist with additional logging during sea trials of the vessel before delivery for normal operations at sea. This provided additional information that has not previously been visible due to the nature of the testing preventing personnel being on board monitoring the systems from the bridge.

The IoT can be connected to an engine ECU using standard j1939 CAN protocol to give live engine data to be able to monitor remotely. This can provide data feedback from various sensors to ensure optimal engine performance and critically, no abuse of the equipment when being used in the field.

Alerts can be set and configured to automatically send emails once thresholds are exceeded, enhancing the effectiveness of automated data upload.

Built in Bluetooth and WiFi also allows the user to access the password protected modem locally to download logs and further enhance the remote experience. Software updates can be performed remotely over the web or by Bluetooth/WiFi to increase the functionality of the sampling controller or change data collection and upload frequency, allowing for maximum end user flexibility for the customer.