The High Efficiency Controllable Pitch Propeller project is part of the Clean Maritime Demonstration Competition, funded by the Department for Transport and delivered in partnership with Innovate UK.

Announced in March 2020, and part of the Prime Minister’s Ten Point Plan to position the UK at the forefront of green shipbuilding and maritime technology, the Clean Maritime Demonstration Competition is a £20m investment from government alongside a further c.£10mfrom industry to reduce emissions from the maritime sector. The programme is supporting 55 projects across the UK, including projects in Scotland, Northern Ireland and from the South West to the North East of England. As set out in the Clean Maritime Plan (2019), Government funding has been used to support early-stage research relating to clean maritime. The programme will be used to support the research, design and development of zero emission technology and infrastructure solutions for maritime and to accelerate decarbonisation in the sector.

Decarbonising marine transport in order to contribute to the UK’s target of net zero by 2050 and the International Maritime Organisation’s target of a 50% reduction by 2050 is a challenging and multifaceted problem that requires new technology to improve energy efficiency and replace onboard energy storage with low greenhouse gas (GHG) alternatives.

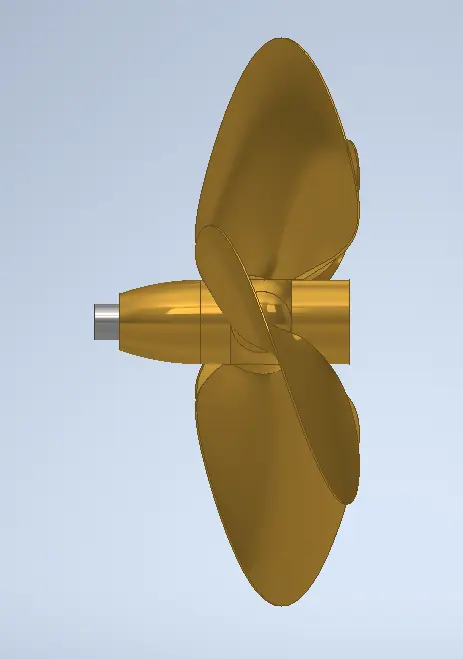

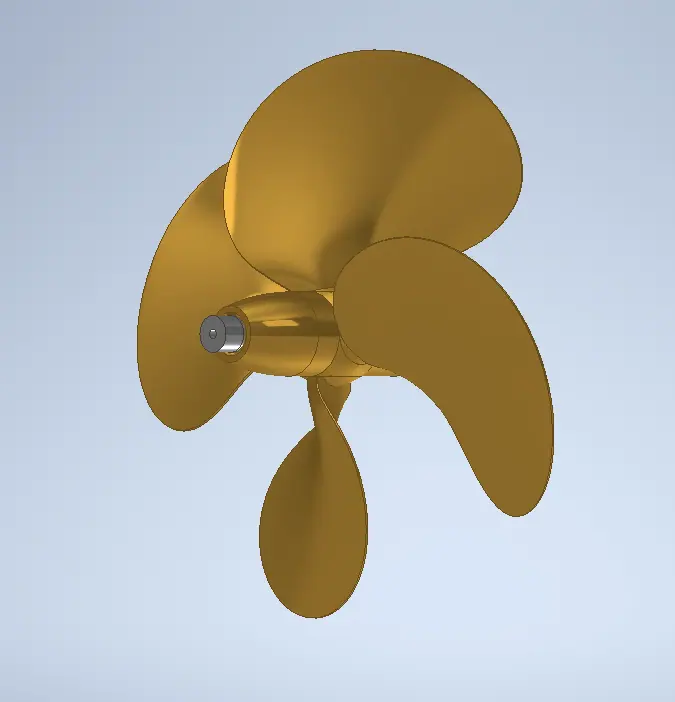

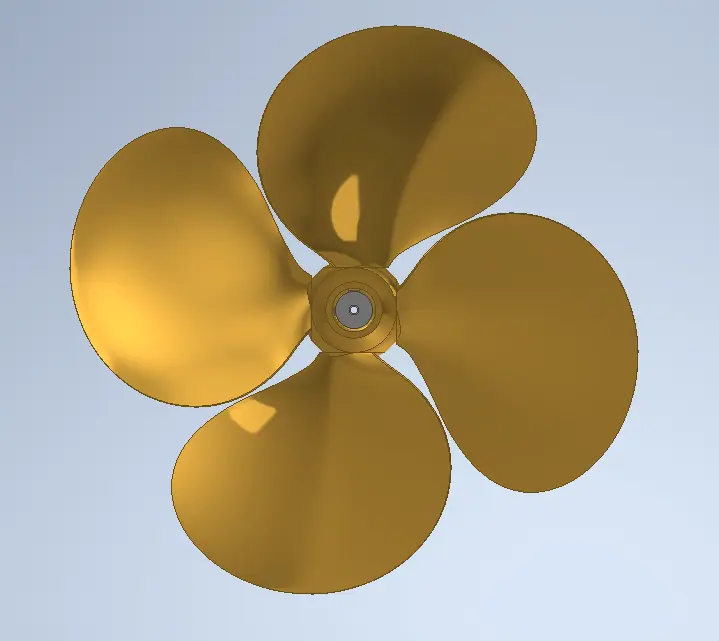

This project seeks to address the energy efficiency aspect of the challenge and in so doing, to reduce GHG emissions associated with traditional fuels and make alternative, lower energy density storage solutions such as batteries and hydrogen more accessible. Teignbridge Propellers International Ltd. (Teignbridge) has undertaken initial development activity on an innovative, patent pending, high-efficiency controllable pitch propeller (CPP) solution which reduces capital cost and improves efficiency when compared to competing CPP technologies. This project will set out to bring this technology closer to market from its current, proof of concept prototyping stage through to at-sea demonstration of the technology on HRV1, a unique propulsion system test vessel.

Previous studies have shown that accurate matching of CPP control algorithms to vessels with highly variable duty cycles can improve efficiency by between 8% – 15% when compared to fixed pitch propeller (FPP) alternatives. The principal barrier to entry for this technology is cost. A key target of this project will be to bring the technology within reach of a much larger portion of the marine transport market.

Mark Phare, Director at Teignbridge commented:

This project provides the stimulus, oversight and context in which to explore an innovative Controllable Pitch Propeller concept that we believe will make this technology and specifically it’s energy saving credentials available to our customer base through capital cost reduction. Teignbridge has been designing and manufacturing propellers at our South Devon factory for over 45 years. With this project we hope to add another product to portfolio and at the same time affect a reduction in carbon emissions and reduction in fuel costs for our customers.