British marine propulsion specialist Teignbridge Propellers has successfully developed a carbon fiber Clamp On Blade propeller through an Innovate UK-funded Clean Marine Demonstration Call (CMDC) project. The advanced propeller system, tested on a 10-meter electric vessel, demonstrated 3-4% efficiency improvements compared to traditional metal blades, marking a significant step forward in marine electrification.

Teignbridge’s Clamp on Blade propeller technology is suited to a wide variety of applications including merchant, commercial, military and leisure vessels and can be supplied in a wide range of sizes from 0.75m to 5.50m diameter with keyed or hydraulic shaft fitting. A 5.5m diameter propeller can be packaged and transported in a 20ft shipping container.

With a hub diameter ratio only 5% greater than a conventional mono-bloc fixed pitch propeller, this represents the lowest hub to diameter ratio replaceable blade propeller currently on the market, maximising the propellers surface area and generating the greatest possible thrust. Unlike alternative, radially bolted solutions, Teignbridge’s Clamp on Blade propellers hydrodynamic efficiency is further improved by minimising the number of bolt heads present on the hub surface resulting in improved flow over and around the hub.

In the unfortunate event that propeller blades become damaged, the individual blades can be replaced rather than having to remove and replace the whole propeller. This feature of the Clamp on Blade system saves the time and cost of having to dry dock or slip the vessel. As Clamp on Blade parts can be stored onboard, there is no wait for replacement parts to be manufactured or repaired, reducing costly vessel downtime. For smaller vessels and superyachts, the modular design provides an economical and flexible option, with blade changes only requiring the services of a diver.

The increased ease with which propellers blades can be changed also means that long-term changes in vessel use profile can be matched with a revised propeller design, improving efficiency, reducing emissions and saving fuel.

Carbon Fibre Clamp on Blade Propeller Option

The carbon fibre composite blade option produces a lightweight and efficient propeller which due to the composite material characteristics, yields lower driveline vibrations combined with substantial noise reduction compared to conventional metallic propellers. This is extremely beneficial when coupled with an electric drive where controlling NVH (Noise, Vibration, Harshness) levels are of upmost importance.

Carbon fibre construction techniques allow the propeller characteristics to be tailored, adding strength and stiffness where required, but also enabling flex to be designed into the blades which can be utilised to enhance the pitch for various vessel conditions and speeds, increasing the propellers efficiency. Lighter propeller weight means smaller diameter shafts can be utilised as the moment of inertia is reduced, putting less loading on other parts of the driveline, in turn reducing their associated weight.

The savings offered by the Clamp on Blade technology and optional carbon fibre blades generates efficiency, emission and NVH improvements that produce a rapid return on investment for the customer.

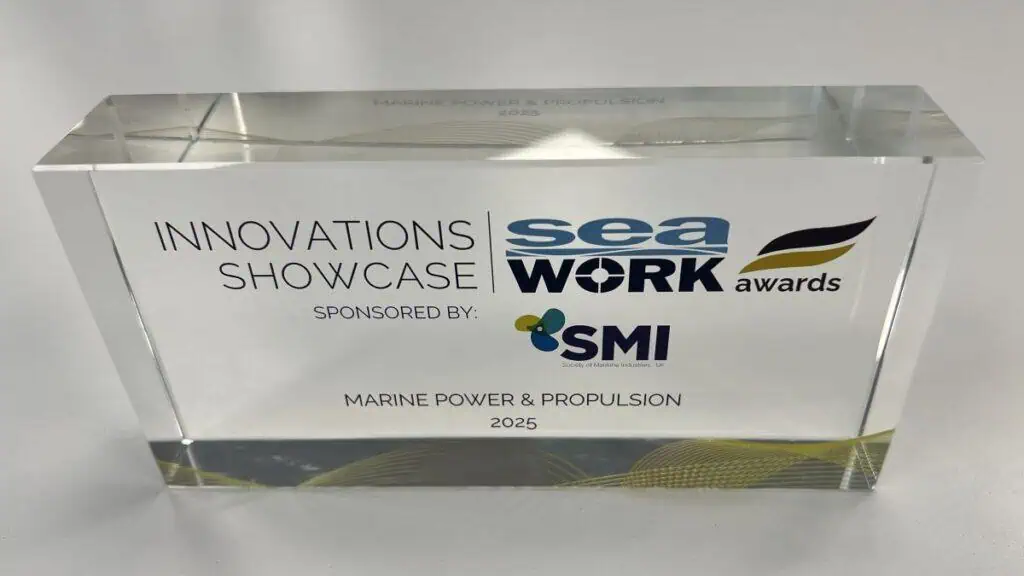

The Carbon Fibre Clamp on Blade Propeller has been awarded the Innovation Award for Marine Power & Propulsion at the recent Seawork 2025 trade show.