HybriGen Power and Propulsion is a flexible system – improving electrical efficiency and vessel range, increasing propulsion power, and simplifying installation.

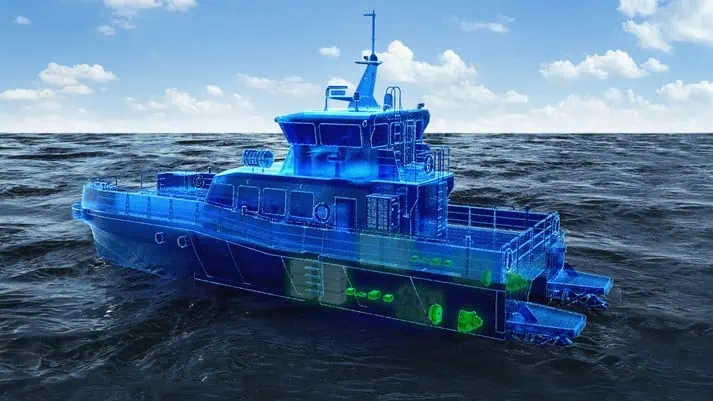

BAE Systems, a leader in electric propulsion, has launched its next-generation power and propulsion system for the marine market. The HybriGen® Power and Propulsion system is a flexible solution to help operators reach zero emissions – improving electrical efficiency and vessel range, increasing propulsion power, and simplifying installation.

The HybriGen Power and Propulsion system uses smaller and lighter components for vessels, building on the company’s 25 years of experience in electric propulsion systems. Its modular accessory power system (MAPS) and modular power control system (MPCS) allow for a scalable, tailor-made solution to fit the specific power and propulsion requirements of a range of vessels, from sailboats and tugs to passenger ferries.

“Our investment in this next-generation technology will provide marine operators with cutting-edge capabilities to create clean transportation,” said Steve Trichka, vice president and general manager of Power & Propulsion Solutions at BAE Systems. “Using a modular design, we can customize our solution to meet the exact needs of each customer, simplifying the installation and improving system reliability. The increased propulsion power and electrical efficiency mean our customers can now accelerate their journey to zero emissions.”

BAE Systems’ electric propulsion technology supports low and zero emission applications with proven controls and components that are available in multiple system configurations.

BAE Systems has more than 14,000 power and propulsion systems in markets around the globe. Each year, those systems contribute to a cleaner world by saving more than 30 million gallons of fuel and eliminating 335,000 tons of carbon dioxide each year – the equivalent of taking 59,000 cars off the road or planting 4.5 million trees.

Work on the HybriGen Power and Propulsion System will be conducted at the company’s facility in Endicott, N.Y.