In the ever-evolving world of renewable energy, innovation is key to overcoming technical and economic challenges. In this edition of Blackfish Engineering Innovators Corner, we detail the journey of CGEN, an advanced electrical generator designed to revolutionize wind, wave, and tidal energy generation. Born from the need to address the limitations of traditional systems, CGEN’s modular, scalable design stands as a prime example of innovation-driven design within the sector. This article explores the origins of this direct-drive generator, the visionaries behind it, its key technical details and finally the next steps in its journey to mass adoption.

Introduction: The Birth of CGEN

CGEN was first envisioned by Markus Mueller in 2005. Recognizing the challenges wind energy systems face, Markus developed a direct-drive generator capable of overcoming the difficulties of assembly, manufacturing, and maintenance in large electrical machines. His idea was to create a modular design that could be easily scaled and maintained, fundamentally changing how electrical generators are utilized in the renewable energy sector.

About the Innovators: Markus Mueller, Joe Burchell and Mike Galbraith

Markus Mueller: Technical Director

Markus Mueller is the original innovator behind the CGEN technology. Markus’s journey began with an undergraduate degree in Electrical Engineering at Imperial College, London, followed by a PhD and postdoctoral work at the University of Cambridge. His early career involved significant industry collaboration, which shaped his approach to research and innovation.

Driven by a desire to address the challenges of direct-drive systems in renewable energy, Markus developed the CGEN concept after he joined the University of Edinburgh in 20244. Markus’s work is characterized by a focus on practical solutions that bridge the gap between academic research and industry needs. In addition to CGEN, Markus has also worked on hybrid renewable systems and superconducting machines, always with an emphasis on modularity and scalability. He holds a Personal Chair in Electrical Generation Systems at the University of Edinburgh and a Chair in Emerging Technologies with the Royal Academy of Engineering to develop a novel, fully air-cored modular superconducting machine for renewables and transport applications.

Mike Galbraith: Manufacturing Director

Mike Galbraith stands as one of the founders of CGEN Engineering Limited, taking on the role of Manufacturing Director. His career began as a machine tool fitter in 1974 before earning a degree in Mechanical Engineering from Huddersfield Polytechnic in 1988. After working in various engineering roles, including at Black & Decker, he co-founded Fountain Design Ltd in 1999, focusing on the design and building of test rigs. Throughout this period, Mike was engaged with a project with Prof. Ed Spooner (retired) to design, construct and test a novel wind turbine generator design.

In 2007, Mike began collaborating with Prof. Markus Mueller at Edinburgh University on the first CGEN generator. Since then, Mike has been involved in the design and build of several radial flux, axial flux and linear CGEN generators and has been instrumental in industrializing the manufacture of CGEN modular generators, working closely with manufacturing partners to meet growing customer demands.

Joe Burchell: Managing Director

Joe Burchell has played a crucial role in advancing the CGEN technology from concept to commercialization. With an undergraduate degree in Mechanical Engineering with Renewable Energy from the University of Edinburgh, Joe’s early career included work in the building services industry, where he focused on integrating modern technologies into historic structures. However, his passion for renewable energy led him back to academia, where he pursued a PhD under the guidance of Markus Mueller.

Since 2015, Joe has been a key player in various renewable energy projects at the University of Edinburgh, including work on Wave Energy Scotland initiatives and developing linear generators for wave and tidal applications. As a Research Fellow at the University of Edinburgh’s Institute for Energy Systems and now Managing Director of CGEN Engineering, Joe has led the efforts to scale and commercialize CGEN technology. His work emphasizes sustainability, modularity, and the circular economy, aligning with the growing demands of the renewable energy sector.

About the Technology: CGEN

CGEN is an advanced electrical machine designed as a direct-drive generator with a unique modular architecture that offers significant advantages over traditional designs. This section explores the key technical features that make CGEN a groundbreaking technology in the renewable energy sector.

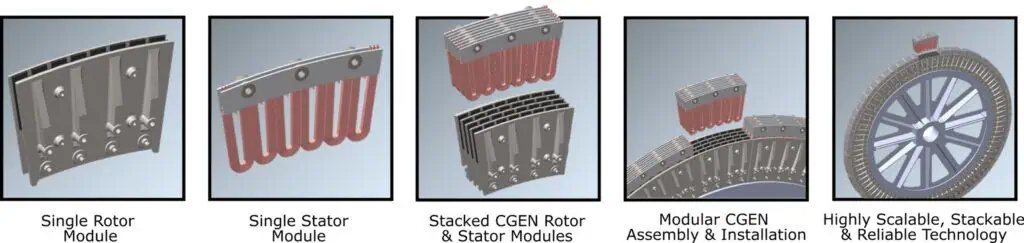

1. Modular Air-Cored Stator Design

The key advantage of CGEN Engineering’s technology lies in its modular design, achieved by removing iron from the stator. This elimination reduces internal magnetic forces, leading to a lighter and simpler machine without heavy structural supports. Additionally, it eliminates cogging torque, enhances efficiency, and reduces vibration. The air-cored stator allows for easy assembly, replacement, and upgrading of modules. This technology also enables the stacking of modules, allowing for standardised sizes across various applications, making CGEN technology adaptable, efficient, and cost-effective to maintain and scale.

2. Double-Sided Permanent Magnet Rotor

CGEN features a double-sided permanent magnet rotor configured in a C-shaped design. This configuration, called the C-core, effectively ensures magnetic flux is focused and contained within the rotor without the requirement of electrical steel laminations. Such a design leads to a more compact, robust machine structure, which is stackable and easy to handle, as magnetic forces external to the C-Core are minimised.

3. Scalability of Design

The modular architecture of CGEN is highly scalable, making it adaptable for a wide range of applications. Whether it’s a small kilowatt-scale wind turbine or a multi-megawatt offshore wind, tidal or wave energy converter, CGEN’s design can be easily scaled to meet the specific needs of the application. This scalability is a critical advantage, allowing the technology to serve diverse markets across the renewable energy sector, from small decentralized systems to large utility-scale projects.

4. Simplified Manufacturing and Assembly

CGEN design allows for rapid and straightforward assembly, which is a significant departure from the complex processes required for traditional direct-drive generators. For example, a one-megawatt unit was completed in three months, from component manufacture to final assembly using basic equipment such as a cherry picker, an overhead crane, and standard tools. This streamlined assembly process contrasts sharply with traditional direct-drive generators, which can take a year or more to construct and require much more intricate and costly manufacturing processes.

5. Rapid Maintenance and Modular Replacement

Maintenance is a major consideration in the design of CGEN. If a fault occurs within a module, it can be quickly and easily replaced without the need to disassemble the entire machine. This was effectively demonstrated during Project Neptune funded by Wave Energy Scotland where a 7m-long linear generator was removed from the water, repaired, and reinstalled within just 40 minutes. This capability significantly reduces operational downtime and the associated costs, offering a practical and efficient solution for long-term energy generation.

6. Adaptability to Different Energy Sectors

CGEN’s versatility is evident in its adaptability across various renewable energy sectors, including wind, wave, and tidal energy. The design can be modified and optimized for specific applications, whether it’s enduring the harsh marine environment of offshore wave and tidal projects or providing reliable energy on land-based wind farms. This adaptability ensures that CGEN can meet the unique demands of each sector, making it a valuable technology across the entire renewable energy landscape.

7. Focus on Circular Economy and Sustainability

Sustainability is at the core of CGEN’s design philosophy. The modular architecture supports a circular economy by allowing individual components to be easily replaced or upgraded, rather than requiring a complete system overhaul. This approach not only extends the operational life of the machine but also minimizes waste and reduces the overall environmental impact. CGEN’s focus on reparability and modularity aligns with the growing emphasis on sustainability in the renewable energy industry.

8. Whole System Optimization

Unlike traditional approaches that prioritize electromagnetic performance, CGEN’s design philosophy emphasizes whole-system optimization. This means considering not only the electrical and magnetic aspects but also the manufacturing, installation, operation, and maintenance processes. By optimizing the entire system, CGEN provides a more practical, efficient, and cost-effective solution, making it an attractive option for developers and operators in the renewable energy sector.

Challenges Faced: Expanding Applications Across Wind, Wave, and Tidal Energy

CGEN’s innovation has had a profound impact across multiple sectors within renewable energy. Initially developed to address challenges in wind energy, CGEN’s modular and scalable design has extended into both wave and tidal energy applications. Previous applications of the technology include:

- 15kW horizontal axis wind turbine generator

- 1 MW horizontal axis wind turbine generator

- 16kW vertical axis wind turbine generator in collaboration with both InnovateUK & Swift Energy

- 75kW linear wave energy generator in partnership with Wave Energy Scotland

- 30kW wave energy generator within the Mocean Energy Blue X device, in which the generator operated successfully in harsh sea states for 18 months of continual operation

- 25kW tidal energy generator as part of the EPSRC Impact Accelerator Account along with Instream Ltd.

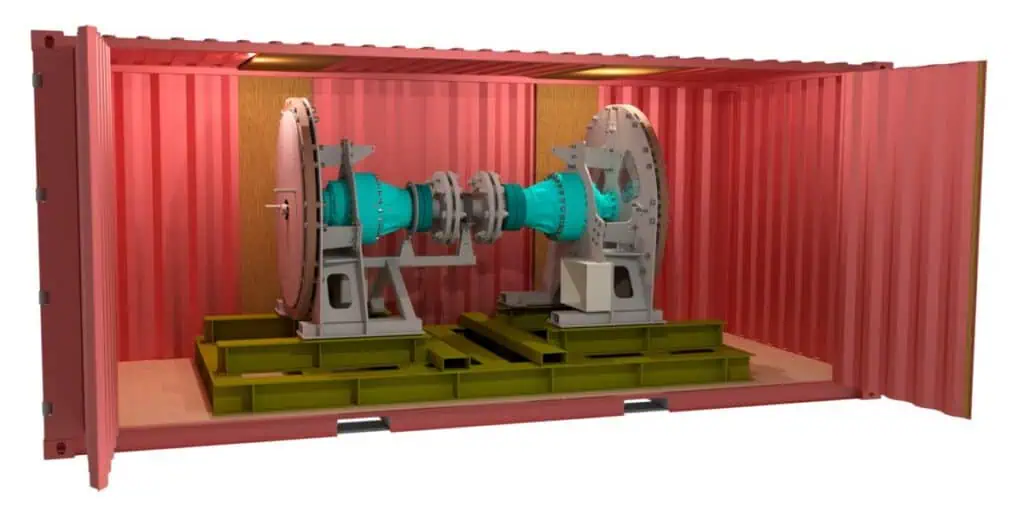

The Role of Blackfish Engineering

Blackfish Engineering aided the University of Edinburgh researchers in the advancement and commercialization of CGEN through application engineering and mechanical interface design. The team at Blackfish has contributed to several key applications, most notably in the design of a back-to-back PTO (Power Take-Off) test apparatus. This apparatus was essential in qualifying CGEN before its installation within the Mocean Energy machine, ensuring that the generator met the rigorous demands of marine energy applications.

Joe Burchell emphasized the importance of Blackfish Engineering’s collaborative approach, stating: “When working on the Blue X design, Blackfish Engineering’s deep commitment to understanding our technology and their close collaboration with our team was instrumental. They didn’t just provide the mounting mechanism and interface; they took the time to truly grasp what we were trying to achieve. This effort ensured that the right solution was developed, and the project was executed flawlessly. Their dedication to working closely with innovators and their attention to detail made all the difference in delivering a successful outcome.”

This quote highlights the value Blackfish places on working closely with innovators, ensuring that the right solutions are developed and executed with precision. Click the button below to get in contact and learn more about how Blackfish Engineering can support and accelerate the commercialisation of your novel technologies.

Looking Ahead: New Opportunities with Horizon and Innovate UK Tide Gen

CGEN Engineering Ltd officially spun out of the University of Edinburgh in September 2024, marking a major milestone in its transition to an independent company. Building on this momentum, CGEN has been successful in securing an Innovate UK-funded project, TIDEGEN, which commenced in November 2024. This initiative will see the design, construction, and testing of a multi-stage modular electrically geared tidal power take-off at the META test site in the summer of 2025. Additionally, CGEN has been awarded £50,000 in pre-seed funding through the Launch50 OCC University of Edinburgh program, supporting its continued growth. The company’s achievements have also been recognized by its selection for the TechX Accelerator 2025 cohort and a nomination for the Earth Shot Prize 2025, further strengthening the team’s position as a leading innovator in renewable energy.

Furthermore, the team at CGEN looks to expand their operations by providing generator systems for wind energy, to both reduce costs, extend operational lifetimes as well as decrease operations and maintenance costs through their modular generator approach.

Conclusion: The Power of Disruption

CGEN’s journey is a testament to the power of innovative thinking and represents a leap forward in the design of electrical generators. As the industry evolves, disruptive technologies like CGEN will play a crucial role in shaping the future of renewable energy. Blackfish Engineering is proud to support this groundbreaking project and looks forward to CGEN’s continued success.