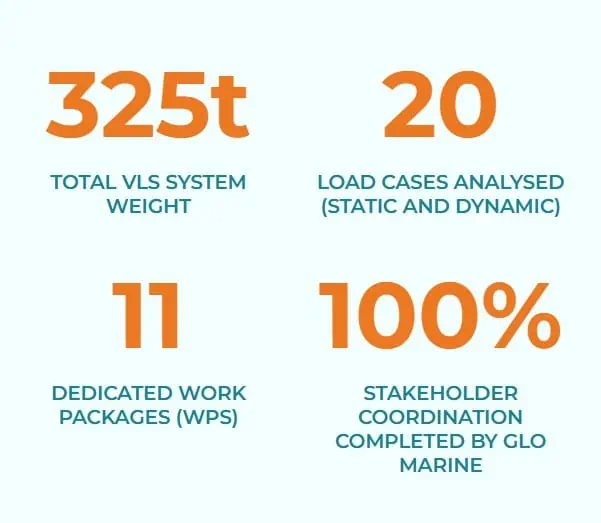

GLO Marine Engineering, a leader in offshore marine solutions, has successfully completed the complex integration of a 325-ton Vertical Lay System (VLS) aboard a 157-meter multi-purpose offshore vessel. This achievement highlights GLO Marine’s expertise in precision engineering and its ability to deliver high-performance solutions under stringent conditions.

The project required meticulous planning and execution due to tight performance margins, strict regulatory compliance, and an accelerated timeline. The VLS, a critical component for subsea operations, enables the vessel to handle heavy loads with enhanced efficiency, making it a vital asset for deepwater construction and installation projects.

The client is a major player in the maritime and offshore industries, with a strong focus on vessel upgrades and retrofits to support offshore energy projects.

For this particular initiative, the end beneficiary had identified a strategic opportunity to repurpose their offshore asset by installing a high-capacity 325t Vertical Lay System (VLS) on board one of their flagship Multi-Purpose Offshore Vessel.

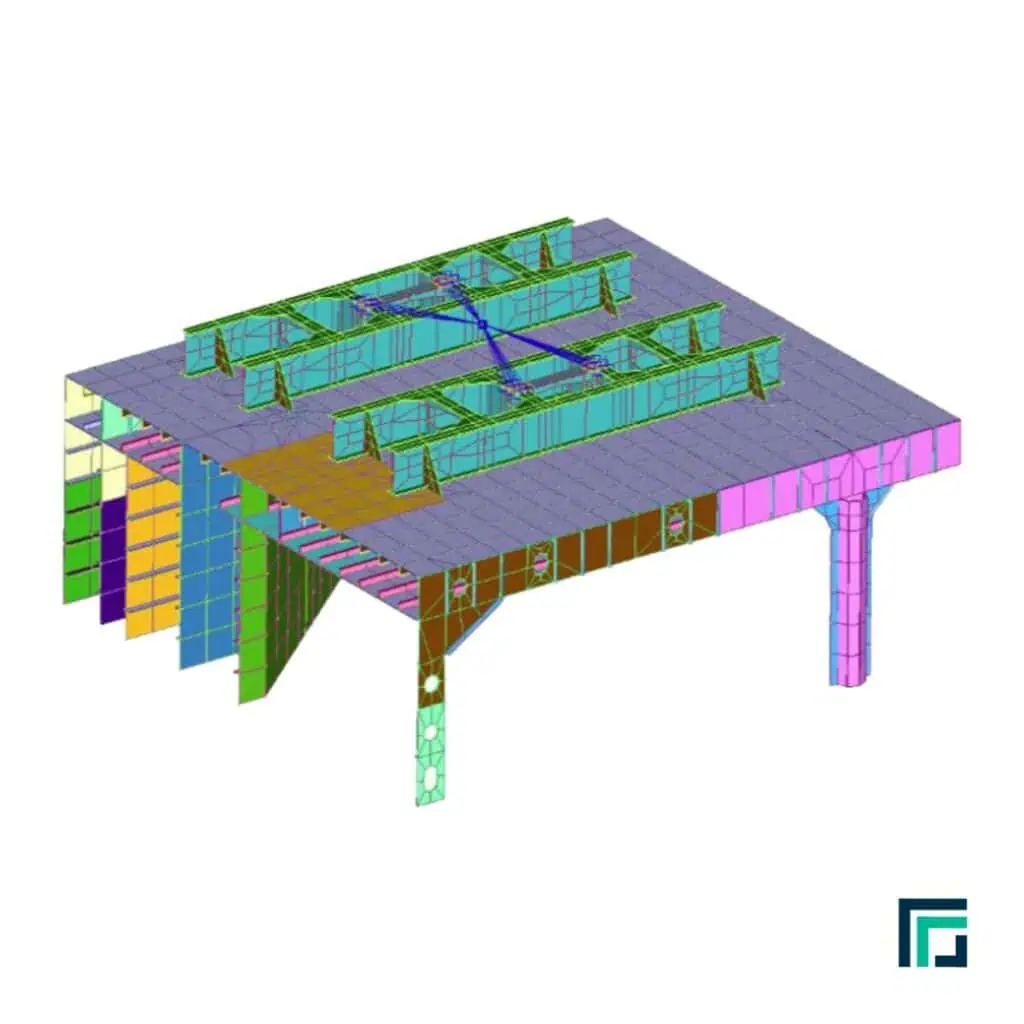

The VLS was to be integrated above the moonpool, requiring substantial structural, systems, and stability modifications.

The Engineering Challenges

- Structurally integrating the VLS over the existing moonpool and ensuring it could withstand all operational and survival load conditions.

- Modifying and strengthening the hull, decks, and compartments to accommodate new equipment foundations.

- Synchronizing multiple disciplines (electrical, structural) while managing client expectations, class approvals, and shipyard constraints.

The Project Phases

GLO Marine was commissioned to carry out the full engineering design and support package for the integration of the VLS, including:

- New compartment design for storage winch, spooling tensioner, and control van

- Lay ramp foundations

- Moonpool modifications

- Carousel loading/Laying hatch

- Ancillary equipment foundations

- Cooling water system upgrade

- Assessment of longitudinal strength

- Carrying capacity and stability book update

- Statutory and layout drawings

Project Solution and Implementation steps

01 – Structural and naval architecture analysis

Using both local and global load scenarios (sagging and hogging), our team developed foundation designs for the Lay Ramp and other critical structures.

A total of 20 static and dynamic load cases were analysed for operating and survival conditions.

02 – Detailed engineering and equipment integration

We produced full detailed designs and FEAs for:

- Lay Ramp hinge foundations (main hinge pins located 1030mm above deck)

- Moonpool side infills and testing beam support structure

- Underdeck reinforcement for the carousel hatch

- Sea fastening and foundations for A&R winch, deflector sheaves, hydraulic power unit, and multiple containers

- Deck gallery extensions and transformer foundation designs in ROV Winch Rooms

03 – Cooling system upgrade

We engineered a full cooling water system upgrade including P&IDs, GA drawings, piping isometrics, and control schematics to support new HPU and electrical equipment loads.

04 – Strength and statutory documentation

Our team conducted a comprehensive assessment of the ship’s longitudinal strength. We also delivered updated statutory drawings (GA, fire and safety, docking).

05 – Class approval

Our dedicated project lead ensured timely submission of all documentation and seamless handling of Class comments, with zero delays.

The Final Outcomes

The VLS and all auxiliary systems were successfully integrated on board.

- Project delivered within the scheduled time frame.

- Optimized foundation and equipment layout reduced yard installation time.

- Positive feedback from the client led to a long-term Frame Agreement for future vessel upgrades.

The vessel was successfully upgraded with a fully integrated 325t VLS system, ready for offshore operations.

All engineering deliverables were completed on time, Class approvals were secured without delays, and installation time at the yard was minimized.