The CSL Group, a global leader in marine dry-bulk shipping, today announced the deployment of its newest vessel, the MV CSL Flexvik. This state-of-the-art, 18,003 DWT hybrid self-loading/unloading vessel has entered service to support complex marine construction projects and aggregate logistics across Europe, marking a significant enhancement to CSL’s versatile fleet.

Engineered for maximum versatility and efficiency, the CSL Flexvik is uniquely capable of handling a diverse range of cargo—from fine sand and gravel used in concrete production to large, 1-3 tonne armour rock essential for coastal protection and infrastructure projects.

Delivered on May 31, 2025, from Wulkan Shipyard in Szczecin, Poland, MV CSL Flexvik is the result of a strategic conversion from a conventional bulk carrier into a purpose-built vessel optimised for flexible, cost-effective delivery of materials for infrastructure and offshore energy projects.

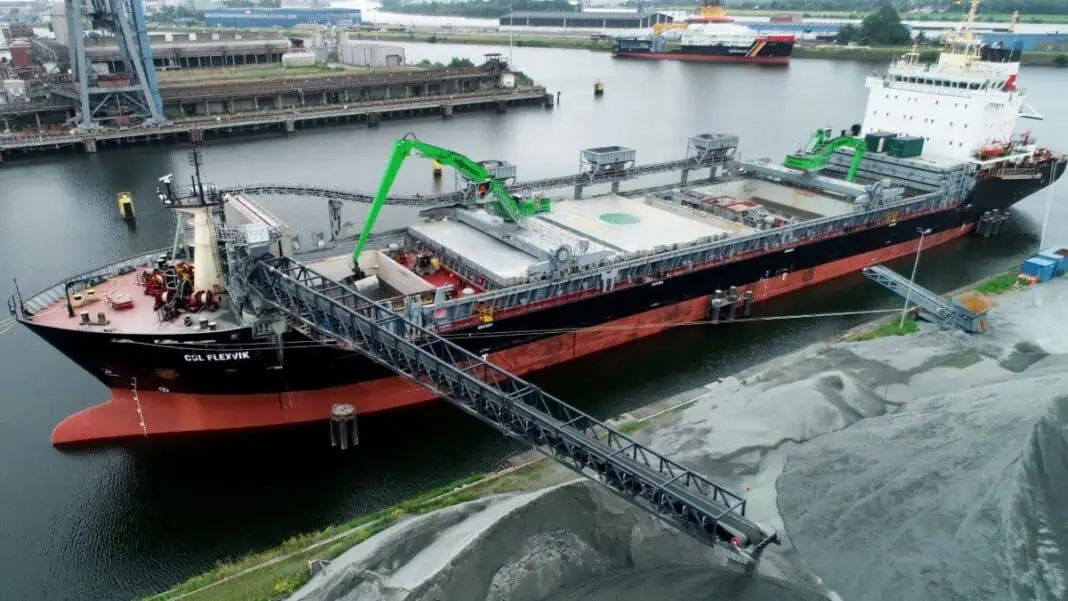

Fitted with two gantry-mounted Sennebogen 870 electric excavators, MV CSL Flexvik can self-load and self-discharge with precision. Cargo can be offloaded via the conveyor belt system, which includes a 45-metre discharge boom, or directly using the onboard excavators. This means the ship can single-point discharge to a stockpile, transload materials to another vessel, and efficiently handle larger rock gradings, discharged directly using the excavators.

“CSL Flexvik brings a new level of operational flexibility to Europe’s marine construction logistics,” said Louis Martel, CSL’s President and CEO. “Its hybrid configuration, flexible rock-handling capabilities, and direct discharge options offer unmatched flexibility for project-based and industrial customers.”

Key Advantages:

- Handles Full Range of Materials: Capable of transporting everything from sand and crushed stone to heavy rock armour.

- Multiple Discharge Options: Offers boom discharge, directly over-side or vessel-to-vessel transhipment.

- Supports Subsea Rock Installation Logistics: Can tranship rock to other vessels, enabling subsea rock installation vessels to remain in situ.

- Reduces Port Time and Costs: Self-operating excavators reduce reliance on shore-based stevedores.