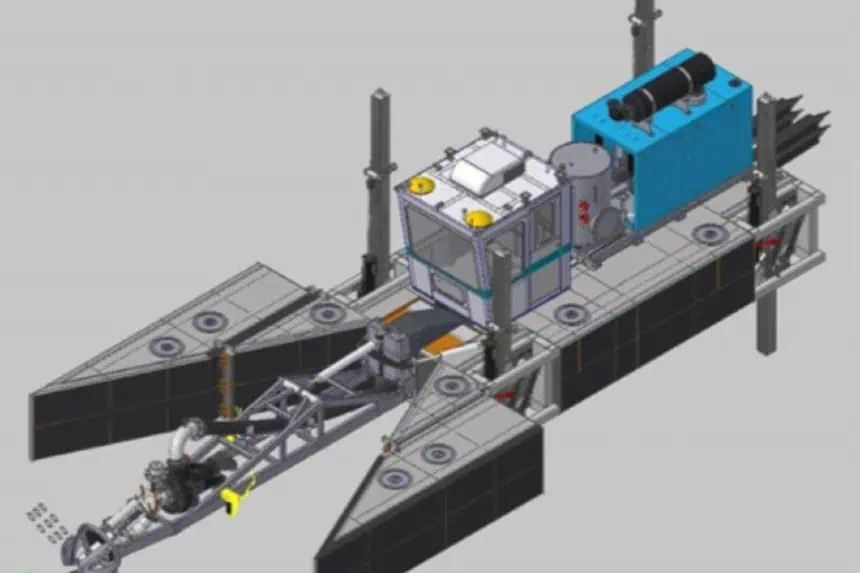

For over twenty (20) years, DSC Dredge’s Moray Class dredge design has remained the same with only minor enhancements made within the last decade. Uniquely offering a swinging ladder configuration along with an efficient submerged dredge pump, the Moray was designed by DSC engineers to be both highly productive and transportable. The Moray excels in promoting the environmental dredging industry trend of pumping low flow rates with higher-percent solids. Leading the way with new technology and designs, DSC has once more raised the bar with its newly improved design to its Moray Class dredge.

The newly improved Moray Class dredge is manufactured for both higher regulated countries requiring Tier 4 or Stage 5 emission engines and lesser regulated regions that do not have these requirements. It can also handle all of DSC Dredge’s newest technology.

Introducing the Walking Spud Carriages – U.S. Patent 10,287,748

DSC’s Walking Spud Carriage apparatus, better known as “spud gliders”, allows seamless forward or reverse dredge positioning without ever losing contact with the bottom. Each of the four spuds individually and automatically repositions itself after stepping which allows for almost uninterrupted excavation. This leads to much greater throughput with much lower operator fatigue.

In addition to increasing dredge efficiency, there are many advantages to the spud glider system on the new Moray Class dredge, including increasing hourly production and decreasing operational costs with a net result of higher profits.

It is key to remember that the Moray Class dredge is suited for applications where flow rates need to be minimized, such as pumping into geotubes, filter presses or retention areas that do not accommodate large volumes of water. It is also well suited for shallow waterway maintenance, lake revitalization, aquaculture, environmental clean-up, erosion control and irrigation projects. Moray Class units, with discharge size of 8 inches (200 mm), meet most single-truck hauling requirements. The Moray Class dredge features include PLC enhanced operator controls and displays, power up/down spuds and gliders, DSC’s Intelligent Flow Meter, and Dredge Rx connectivity.

In addition to these premium features that maximize operational efficiency and longevity, every Moray Class dredge customer benefit from DSC Dredge’s ability to customize each standard production model to fit exact applications and production requirements. These customizations include swing winches for conventional mode operations, traveling spud carriage, dredge automation, larger or smaller dredge size, extended digging depths, production instrumentation and DSC Vision.

New and improved Moray Class dredges will be available for purchase starting mid-2021.

DSC is a global leader in the dredge manufacturing industry, engineering superior customized dredging solutions to meet specific application needs, while continuing to exceed customer expectations. DSC Dredge designs and manufactures high quality, durable cutter suction dredges. At DSC Dredge, we help customers make THE RIGHT CHOICE. Quality, Innovation, Service, Commitment and Customization are key DSC attributes which explain why customers choose to work with DSC. DSC Dredge operates from three manufacturing facilities located in Reserve, LA, Poplarville, MS, and Greenbush, MI. For more information about the company and its products, services and customized solutions, please visit www.dscdredge.com