The 21-metre long all-electric catamaran is being built by Ostseestaal and Ampereship. We are delighted that the Hanseatic and university city has placed its trust in us by awarding the contract to a regional producer,” says Dr. Thomas Kühmstedt, Technical Director of Ostseestaal and Managing Director of Ampereship GmbH. “In our group of companies we are thus continuing the previous successful development of fully electric ships for professional inland navigation”. In the last few years Ostseestaal has built ten electric solar ships for various applications. Most recently, the “Sankta Maria II”, the world’s first fully electric car ferry for inland waters, which operates on the Moselle.

“In the invitation to tender for the construction of the new ship with a very challenging task, the Ostseestaal GmbH & Co KG, a bidder who has made a good name for itself as an innovative company in our federal state, prevailed”, emphasises Dr. Chris Müller-von Wrycz Rekowski, Senator for Finance, Digitalisation and Order of the Hanseatic and University City of Rostock. “A fast and reliable connection of the urban areas east and west of the Warnow is of great importance for our city. With the new electro-solar ferry we want to make a real quantum leap here.”

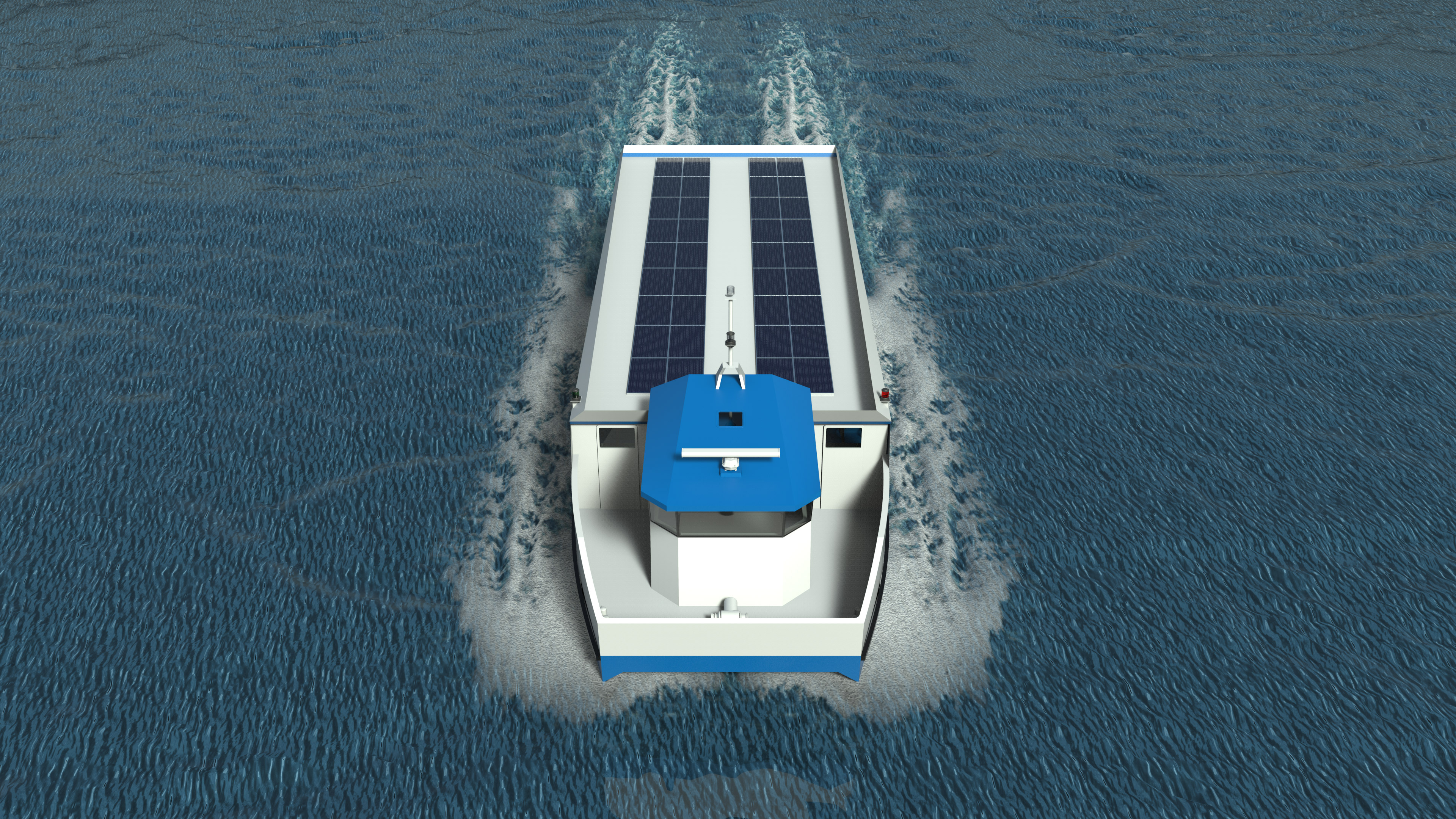

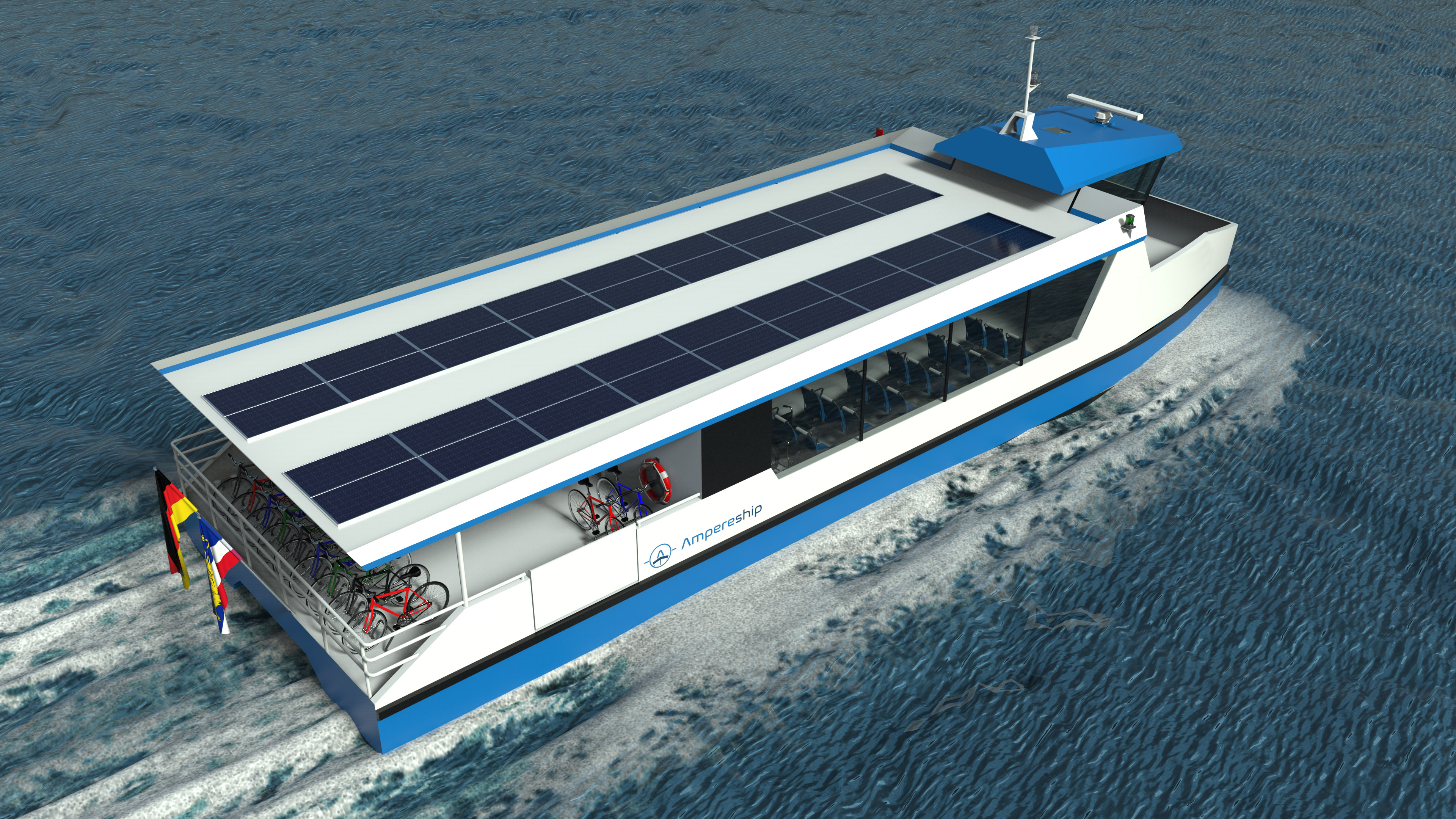

“We are bringing the experience gained in our previous projects into the current new building,” explains Ingo Schillinger, the responsible manager of Ampereship GmbH. The new electro-solar passenger ferry is intended for use in Rostock’s city harbour, where it is to commute over a distance of half a kilometre between Kabutzenhof and Gehlsdorf from mid 2021. The hull of the catamaran will be made of steel. The ferry will carry up to 80 passengers and 15 bicycles on one tour, fully electric and completely emission-free. The propulsion power for the two 45 kW rudder propellers is supplied by high-performance batteries, which are charged by a total of 36 solar modules installed on the roof of the ship. According to Schillinger, the catamaran designed by Ampereship reaches a top speed of 14 km/h, whereas a service speed of 7 to 8 km/h is sufficient for the realization of the schedule. The use of the environmentally friendly electric-solar passenger ferry in inner-city traffic on the Warnow River will save up to 36,000 liters of diesel per year. “We bring e-mobility to the water”, Dr. Kühmstedt underlines the credo of the electric-solar-shipbuilders from Strelasund.

Against the background of the corona crisis, Dr. Kühmstedt emphasised that the acceptance of the latest electro-solar shipbuilding project had proven the long-term strategy of Ostseestaal not to act unilaterally as a maritime supplier for shipbuilding. Ostseestaal has been working for many years for clients in aircraft construction, the wind energy sector and tank industry as well as in architectural projects. The construction of the Rostock electric-solar passenger ferry also underpins the company’s expertise in the manufacture of turnkey end products.

In order to be able to meet the demanding tasks at the Stralsund location, the company is still looking for qualified specialists in the fields of welding and hot straightening and relies on the continuous training and further education of its approximately 200 employees.

| Length: | 21,00 m |

|---|---|

| Width: | 6,60 m |

| Service speed: | 7,5 km/h |

| Maximum speed: | 14 km/h |

| Number of passengers: | 80 |

| Number of bicycles: | 15 |

| Solar panels: | 36 (total 10.8 kWp) |

| Battery capacity: | 252 kWh |

| Propulsion: | 2 x 45 kW – Rudder propeller |

| CO2 savings: | approx. 95 t/Jahr |

Currently, Ostseestaal employs around 200 people. Ostseestaal GmbH & Co KG is a specialist company for the production and delivery of precisely fitting kits made of cut and three-dimensionally formed sheet metal. Materials of the highest quality such as steel, stainless steel, aluminium and special alloys are processed. Ostseestaal is active in the world market for shipbuilding, industry, renewable energies and architectural projects and supplies products worldwide and on a turnkey basis. The Stralsund company has the know-how for technical planning as well as structural execution of innovative and customer-specific projects.