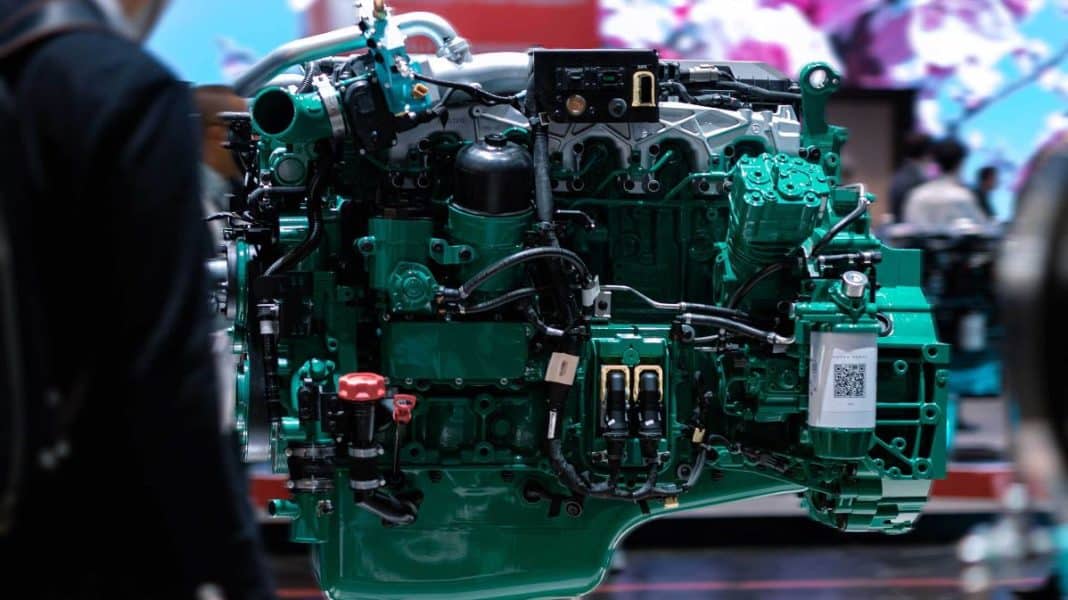

The combustion engine has a track record of reliability, high performance, and innovation. By making it compatible with alternative fuels, such as hydrogen, it can remain a mainstay of modern industry while at the same time helping the industry move toward net zero emissions. Using hydrogen as a fuel can reduce CO2 emissions by up to 80% in a hydrogen-diesel dual fuel solution (depending on the application). So, how does such a dual fuel solution work, and how is Volvo Penta working towards achieving net zero emissions for the industry?

What are the advantages of hydrogen as a fuel?

Hydrogen can be a non-fossil fuel source that helps put industrial operations on the path to net zero emissions. When sustainably produced using renewable energy, green hydrogen can be an efficient, low-emission, flexible energy source. These hydrogen power solutions can then be used within a wide variety of industries, including material handling, agriculture, forestry, construction, mining, special vehicles and gensets.

With a hydrogen-diesel dual fuel solution, or hydrogen power solution for short, the engine’s performance can be the same as that of a regular diesel engine. However, the dual fuel engine will be able to run on a mix of hydrogen and diesel (or HVO and other compatible renewable fuels), thus significantly lowering its CO2 emissions. Since the dual fuel engine can continue to perform entirely on diesel or HVO, should the hydrogen supply run low, uptime can be maintained and operations run smoothly.

A hydrogen-diesel dual fuel solution allows businesses to capitalize on earlier investments in pre-existing diesel power solutions. Making the switch can be easy, with modification to the machine setup and the powertrain/driveline installation.

Starting the energy transition with hydrogen dual fuel engines

Volvo Penta has embarked on a partnership with CMB.TECH, on our hydrogen dual fuel solution. This collaboration focuses on:

● Efficiency, flexibility, reliability; ensuring uptime in all sorts of industrial operations.

● Facilitating a switch to more sustainable fuel sources and, in turn, operations.

● Merging and utilizing expertise and technical capability, in order to create better solutions for the market.

Our partnership ethos is strong, and it is a cornerstone of our work with decarbonization and net zero emissions technology. Presenting a power solution that can run in part on hydrogen is an important step on the road toward net zero emissions; for Volvo Penta, but also for the industry at large. It is part of a process driven by market and customer demand on the one hand, and technical capability on the other. By collaborating with CMB.TECH, we are able to push this process further, and do so faster.

As a start, we are basing this hydrogen dual fuel solution on our D8 EU Stage V engines, alongside the recommendation to customers and fleet owners to fuel with green hydrogen. The data collected from these pilots will provide new insights and help refine both our product offering and the customers’ purpose-built dual fuel solutions.

What’s next for Volvo Penta’s hydrogen power solutions?

Looking ahead, what can customers expect from Volvo Penta’s work with net zero emission technology and hydrogen power solutions?

Our strategy is a step-by-step approach, with continued collaboration and partnership with OEMs, customers, and dealers. As for our hydrogen dual fuel offering, we will gradually introduce it to a growing number of OEMs. We need to both explore and secure the total value that our hydrogen power solutions bring to customers. As such, we are looking at different configurations and arrangements that match their applications, machines, and business requirements.

We leverage the advancements within the Volvo Group as a whole to support our progress forward. From this, we are able to make our hydrogen power solutions adapt better and faster to different industrial applications. Moreover, it means that we can be a truly knowledgeable and innovative partner to OEMs and our customers. It is by working alongside them, and constantly learning more as we do, that we are able to create the next generations of purpose-built, emission-lowering hydrogen power solutions.