Swedish water treatment specialist SurfCleaner has completed its first pine oil clean-up project for a major European port.

The work was delivered within the inner harbour of a large international logistics and cargo handling hub, following a pine oil leak during the ship-to-shore transfer process. The incident happened after an operator within the port experienced a leak causing pine oil to enter the storm water system.

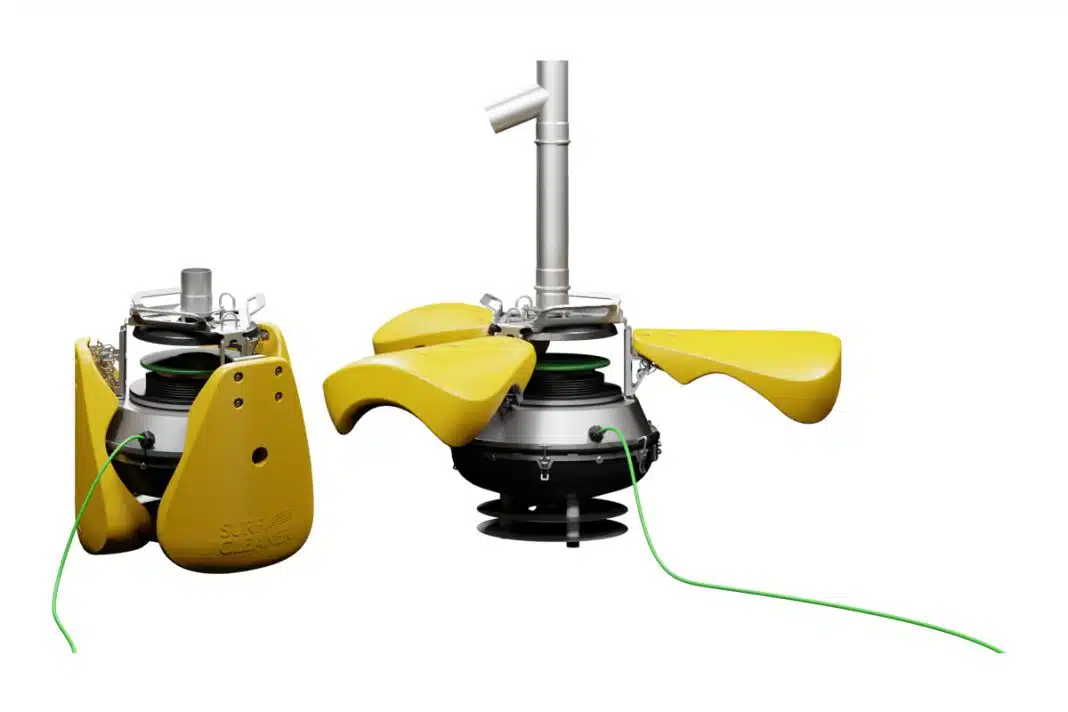

SurfCleaner performed a rapid response, deploying its versatile and compact SCO 1000 skimmer/ separator device, within 90 minutes of the alarm.

SurfCleaner engineer Ricardo Cambra said: “When we arrived, there was a vacuum truck attempting to siphon the surface water. Our SCO 1000 device was quickly deployed and able to perform a much more rigorous operation separating and collecting the pine oil from within the harbour’s water treatment plant basin. Within 24 hours of this first call out further pine oil residue was found within a well connected to the sewerage system where we again installed an SCO 1000 device to tackle the issue. Pine oil is a hugely popular solvent, used in industrial applications for gums, resins, and other substances. However, it presents a significant issue when it comes to spills. In this instance it reacted with other petroleum-based products and emulsified creating a tough sludge, which is particularly difficult to collect. If it enters the sewerage network it travels to the water treatment system where it can damage equipment such as sand filters, which are costly to replace.”

SurfCleaner’s world first hybrid skimmer separator treats a variety of water surface contaminants – including oil, diesel, petrol, plastics, sludge and other pollutants. The technology has major potential across the maritime industry including harbours, coastlines and nearshore markets, with SurfCleaner notably partnering with renowned UK operation Briggs Marine to extend its market reach.

According to statistics from ITOPF (International Tanker Owners Pollution Federation) most oil spills originate near port. The non-profit organisation – which provides technical advice for ship-sourced spills – calculates that circa 80pc of tanker spills arise from operational incidents including loading, discharging and bunkering.

“There were a number of specific areas where the SCO 1000 impressed our client during the pine oil clean-up operation,” added Ricardo. “Firstly, the speed in which we tackled the issue. Our streamlined and lightweight machines are easy to transport and deploy in restricted locations. They can be moved by one person and run autonomously if necessary, managing oil spills across different areas, from wells, basins, plant operations to the harbours themselves. Secondly, SurfCleaner’s machines are also the only systems in the world capable of removing and separating water sheen, which is particularly relevant in oil-spill clean ups, removing the need for costly absorbents. Due to the level of performance, the client has kept the machines on site through a rental agreement, with a view of purchasing long term.”

The SCO 1000 device requires just 20W on average of electricity, equivalent to a small household lightbulb, making it ultra-energy efficient. Other comparable devices require circa 7.5KW, close to 13 times the energy demand. This low power profile means devices can be operated using mobile batteries for up to four days.

Around 40 SurfCleaner units have now been installed in the oil-water separation segment, serving a variety of customers including the Swedish Coast Guard, Preem Refinery, Esso Refinery, Sonatrach Refinery, Exxon Mobil and Ports of Stockholm