Gulf LNG Tugs of Port Arthur, announced the order of four state-of-the-art Robert Allan Ltd designed RApport 2800 tug to support operations at the Port Arthur LNG export facility. These vessels are equipped with high horsepower, are highly manoeuvrable, and feature advanced Low Emission technology, aligning with the growing emphasis on sustainability in the maritime and energy sectors.

Of the four vessels ordered, two will be built by Master Boat Builders, Inc. in Coden, Alabama, and the other two by Sterling Shipyard, LLC in Port Neches, Texas. The decision to partner with these reputable shipyards underscores Gulf LNG Tugs’ commitment to investing in high-quality, locally constructed vessels.

Gulf LNG Tugs is a joint venture comprised of renowned industry leaders Bay-Houston Towing, Moran Towing Corporation, and Suderman & Young Towing Company.

This marks the fifth LNG Terminal along the Gulf Coast for the Gulf LNG Tugs group, the largest provider of LNG terminal services in North America. Leveraging its extensive tug fleet and comprehensive local support, Gulf LNG Tugs is honored to provide service to the Port Arthur LNG facility.

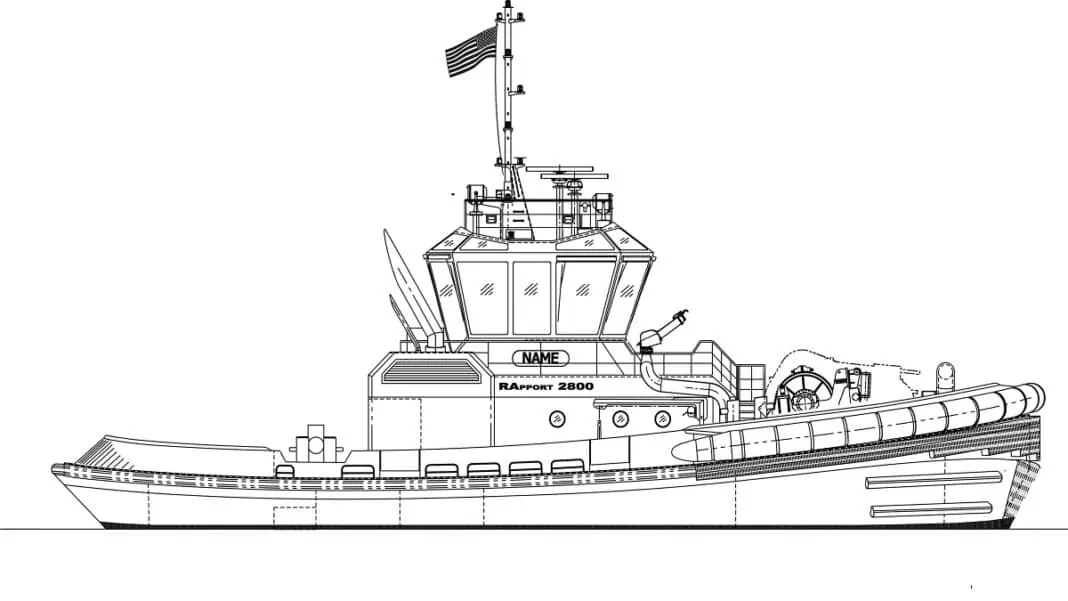

The RApport 2800 tugs, designed by naval architect Robert Allan Ltd., feature a compact design providing increased manoeuvrability in ship handling and escorting through waterways while including the latest in environmental and safety technologies. Gulf LNG Tugs members each currently operate tugs of a similar hull design within their commercial fleets, with an additional four under construction. Each vessel is being designed and built to stringent safety and environmental standards, to exceed the U.S. Coast Guard Sub-M regulations and ABS classification. The eco-designed tugs will feature EPA Tier-4 emission standard Caterpillar 3516 E main propulsion engines connected to Kongsberg US-255 FP-Z drives. Additionally, the tugboats will be outfitted with a Markey DESF-48-100 Electric Class III hawser winch to ensure optimal performance, including a Render-Recover feature for full bollard pull capacity, a feature that furthers escort capabilities.

With an overall length of 92 feet, a beam of 40 feet, and a bollard pull capacity of more than 85 metric tonnes, each tugboat will be equipped with firefighting capabilities that exceed ABS Fire Fighting Vessel 1 (FFV1) classification to further enhance safety measures during terminal support operations.