Fast, safe underwater repairs at Sohar anchorage allowed the RORO vessel to remain operational until its next scheduled drydocking.

When a RORO vessel at anchorage in Sohar was discovered to have severe damage to its bottom hull plating following a grounding, the shipowner faced a familiar challenge: either schedule an unplanned and costly drydock visit or find a way to keep the vessel operational until the next scheduled drydocking.

Turning to Hydrex for a solution, the owner received a proposal that combined speed, safety, and full compliance with classification society requirements. Hydrex recommended temporary, fully class-approved repair work carried out entirely underwater, avoiding the need for immediate drydock

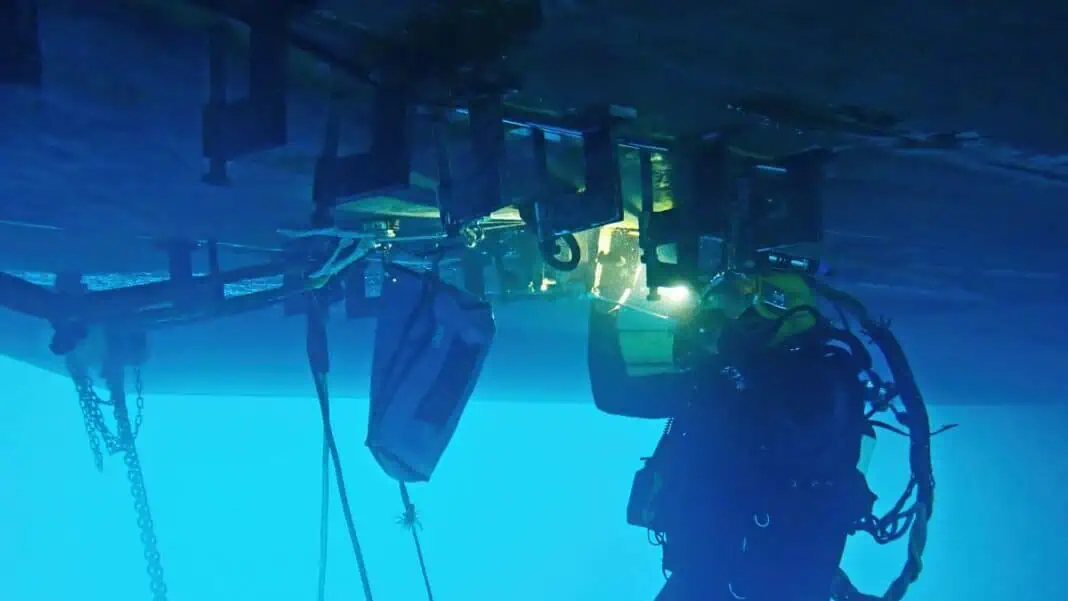

In mid-November, one of the Hydrex diving teams mobilized to the vessel’s location in Sohar. Working from a dedicated workboat carrying all the necessary equipment, the technicians performed an underwater inspection that confirmed tearing in the hull plating at frame 124 on the starboard side. The damage required immediate attention to prevent further cracking and to ensure the vessel could continue operating safely.

A controlled, class-approved temporary solution

To stabilise the affected area, the team first drilled crack-arrest holes at the extremities of the tear. This prevented further spreading of the damage. This was an essential step before any protective structure could be installed.

After thoroughly cleaning the hull surface, the divers positioned a tailor-made steel doubler plate measuring 2000 × 1225 mm and 8 mm thick over the damaged area. The plate was secured using screw dogs before being fully welded to the hull. This provided a solid and watertight connection. A protective epoxy coating was then applied to safeguard the repair.

All work was completed smoothly within a two-day operation window, allowing the vessel to remain at anchorage and resume its schedule without interruption.

Avoiding disruption and gaining control

As a result of this operation the owner avoided an unplanned drydocking, along with the associated costs, logistical challenges, and operational delays.

Instead, the vessel was able to continue trading safely and efficiently. The temporary doubler plate will remain secure until a permanent repair can be carried out during the vessel’s next planned drydock at a time and location chosen by the owner. This allows him to keep full control over budget, scheduling, and yard selection.

This flexibility is exactly what many operators seek when unexpected underwater damage occurs. The Hydrex rapid response and ability to perform complex repairs entirely underwater means that emergency yard visits are not the only option.