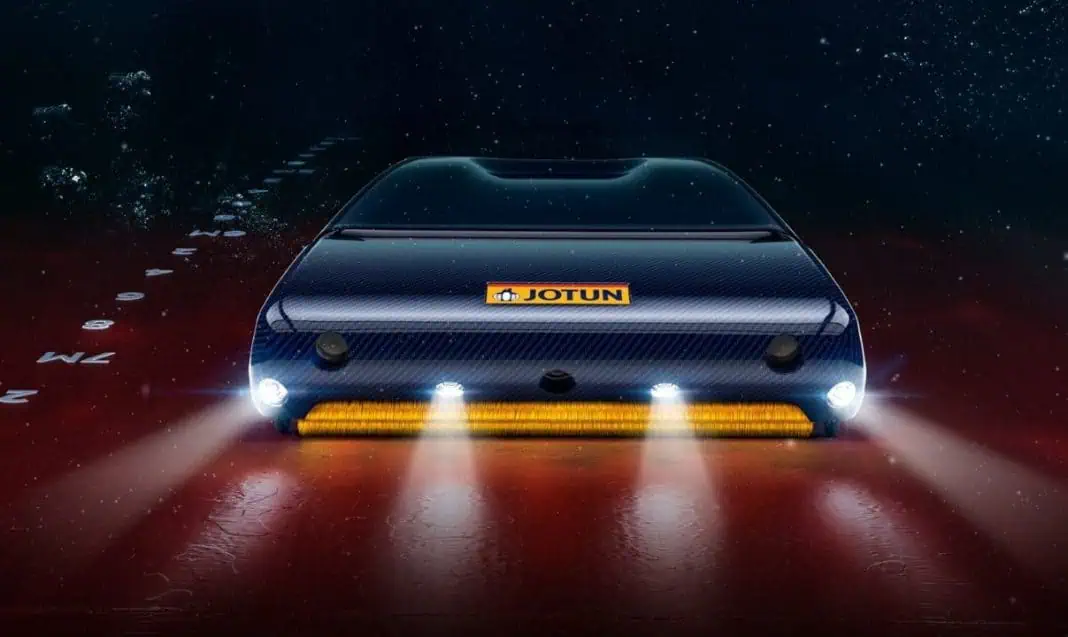

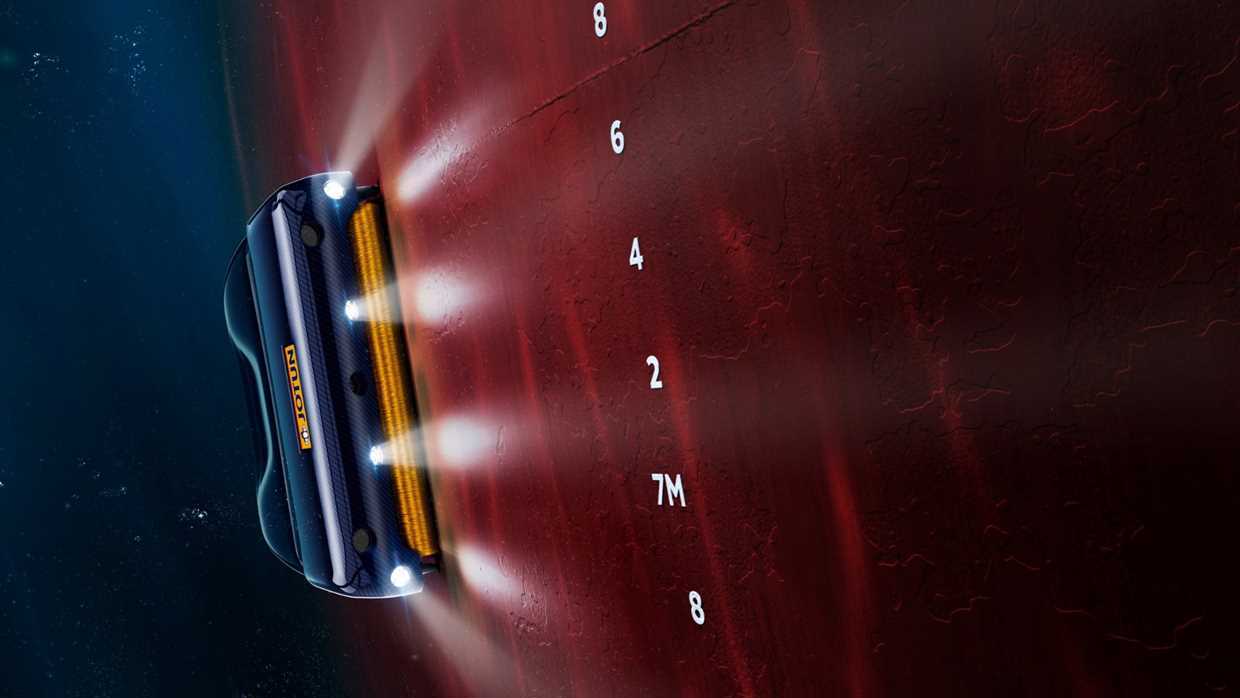

The main function of the HullSkater is to keep the ship’s hull clean for fouling and where this is done through a proactive cleaning system.

“About 70% of the fuel consumption is used to drive the hull through the water and where fouling on the underwater hull is part of the friction / resistance through the water. Fuel consumption can be reduced by an average of 15% on those vessels that experience a lot of fouling by keeping this clean with frequent cleaning processes, says Kjell Gjestad, Senior Vice President on Vessel Robotics in Kongsberg Maritime.

How have the figures been shown to show how much greenhouse gas emissions hole skates can help reduce?

“For 10 years, Jotun has monitored very many ships and where through this work they now have good experience of how fuel consumption is affected by the amount of fouling”.

What is the business model of Jotun and Kongsberg on this product?

“The business model has a combination of customers having to pay up-front for the new coating system and the HullSkater system being delivered as a service model. This means that the investment has a low level of impact and where they can use some of the cost savings from reduced fuel consumption to pay for this cleaning service. This will make this investment more attractive and easier for those customers who today have challenges in investing in the green shift on their ships. Jotun both owns and operates the washing robot with a remote-control system from KONGSBERG”.

What are the experiences so far with the use of the Hullskater?

“We see that the washing robot as its main function cleans the hull well, it exceeds the washing results that were the goal of the project. We are still in a technical evaluation phase and where we are now testing the product system with a view to driving dynamics performance and product stability. We therefore take new steps every month to get the product system technically in place. We know that keeping the hull clean provides major cost savings on fuel consumption and thus reduces emissions of environmental gases. Interest in the market is rising and with the new IMO requirements coming into force from 2023, this system will be the right solution to achieve a good economy on its investment”.

HULL SKATING SOLUTIONS

Hull Skating Solutions is a break-through in proactive cleaning, offering shipowners an always clean hull in the most challenging operations.

How will Kongsberg and Jotun now convince the market to use this service?

“KONGSBERG and Jotun are actively working to establish good reference customers who can be the market’s independent marketers. Jotun works aggressively and professionally in the market to communicate this new innovation as the Hull Skating Solution concept is. There are many cleaning companies that perform reactive washing of ships in port areas. But there are no suppliers who place a washing robot on board the ship and which allows the ship to be washed every time the ship is stationary. This means that we keep the ship’s hull clean at all times and then become the only supplier who delivers a system with proactive cleaning”.

How does Vessel Robotics experience the partnership with Jotun?

“The partnership with Jotun is very good in that we complement each other well with their respective expertise and finances. The collaboration is constantly on the search to optimize this value chain and where we study new opportunities that these two companies can contribute, in order to again satisfy the customer’s need to invest in an efficient and green ship”.

TEXT:Ove Ronny Haraldsen