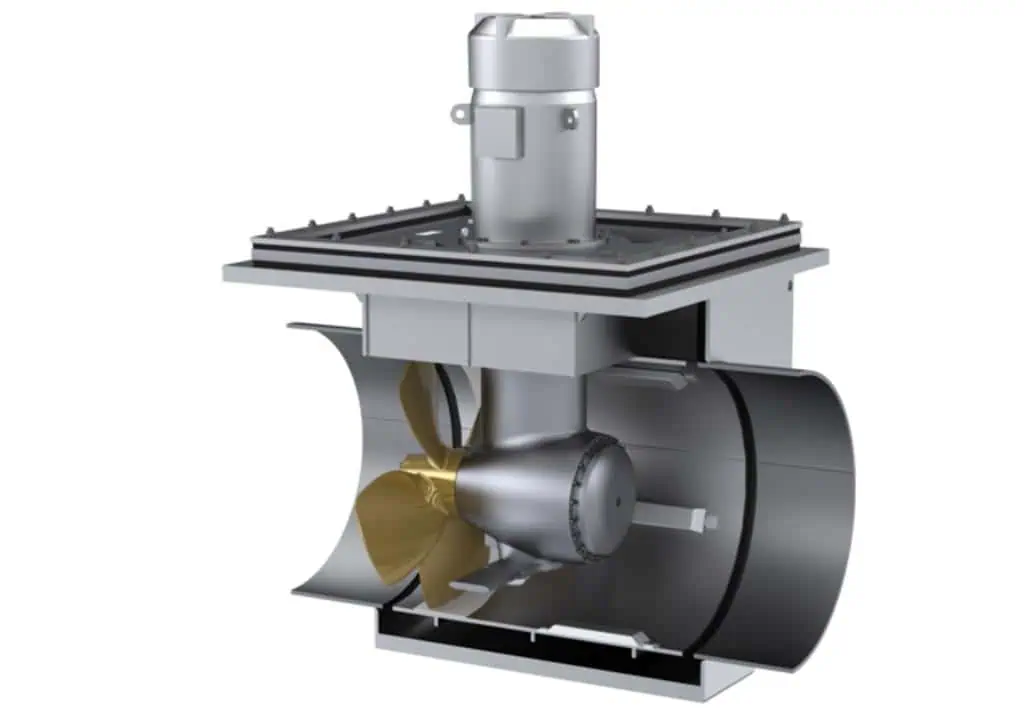

The proven SCHOTTEL TransverseThruster with elastically mounted well installation guarantees greater comfort and reduces noise emissions by up to 11 dB. In addition, the noise-optimized STT helps reduce underwater noise. The particularly low-vibration design of the STT is suitable for ships of all types and sizes, especially for service vessels (SOVs), which must be characterized by maximum comfort and high DP accuracy.

Flexible access for easy maintenance

In addition to the reduced noise generated by the propeller and its surrounding structure, well installation has another advantage: Since the drive is not welded to the ship’s structure, flexible access to the drive is possible. This simplifies maintenance work and eliminates the need for propulsion-related stays in the dry dock. In this way, downtimes can be kept as short as possible and high availability of the ship can be guaranteed.

The flexible well installation is available for SCHOTTEL TransverseThrusters with a power range from 125 to 6,500 kW.

Germany’s most modern research ship

ship The survey, wreck search and research ship Atair of the Federal Maritime and Hydrographic Agency (BSH) is equipped with propulsion solutions from SCHOTTEL. In addition to a SCHOTTEL PumpJet, the propulsion system of the SILENT R-classified Atair includes a SCHOTTEL TransverseThruster type STT 170 (200 kW) in the stern and a SCHOTTEL TransverseThruster type STT 1 (330 kW) in the bow.

Elastic well installation for the Atair

In order to reduce the noise development of the STT 1 in the Atair to a minimum, the dynamic behavior of the transverse jet system was extensively analyzed and designed in such a way that structure-borne noise is as low as possible. Vibrations and pressure pulses are additionally reduced by a low propeller load and a noise-optimized design of the five propeller blades.

Propulsion by experts

SCHOTTEL has been manufacturing transverse propulsion systems since the mid-1960s. Decades of propulsion expertise combined with the latest technologies ensure that the systems optimally meet the needs of the customers. More than 100 engineers worldwide work hand in hand every day to create products and solutions that prove their reliability and performance in practice. The drive systems are manufactured in German factories in compliance with the highest quality standards.