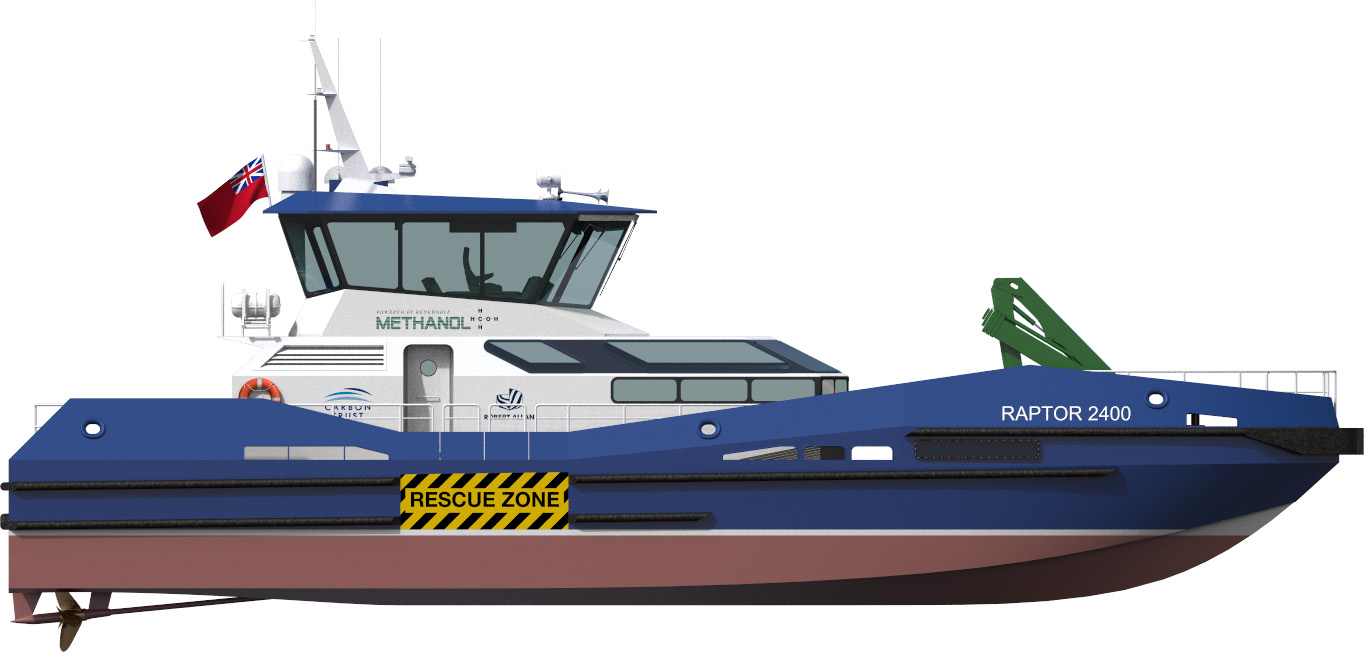

With support from the Carbon Trust, UK and the Offshore Wind Accelerator program, Robert Allan Ltd. has brought the offshore wind industry closer to eliminating carbon emissions from the supply chain, with the development of a methanol-fueled RAptor 2400 Crew Transfer Vessel (CTV).

As a marine fuel, methanol provides emissions benefits that are similar to natural gas when it comes to reducing CO2, NOx, SOx, and particulates, but without the need for cryogenic or pressurized fuel tanks. This reduces capital cost, saves space and allows more fuel to be carried. With the advent of green methanol – produced from sustainable low carbon sources including renewable electricity with carbon capture – well-to-wake carbon emissions can be reduced to net zero by switching to green methanol as it becomes more widely available in the years to come; a seamless transition requiring no changes to the vessel.

“The possibility of using green methanol marks a shift from the current linear fuel cycle to a circular fuel cycle, where harmful combustion waste products are converted back into useful fuels. This will have great benefits for generations to come,” said Erik Johnston, P.Eng., Project Manager for Robert Allan Ltd.

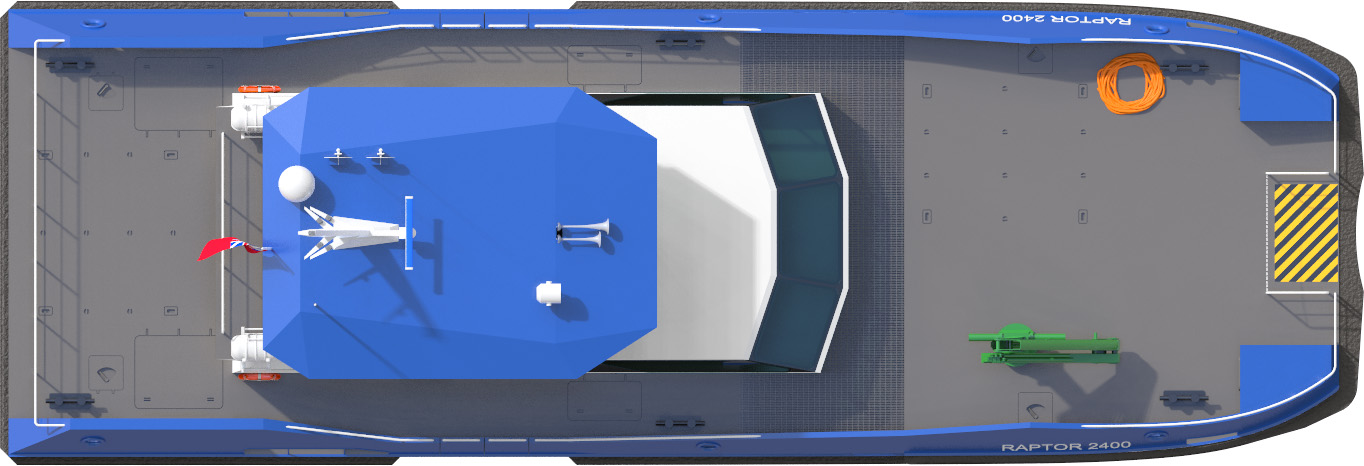

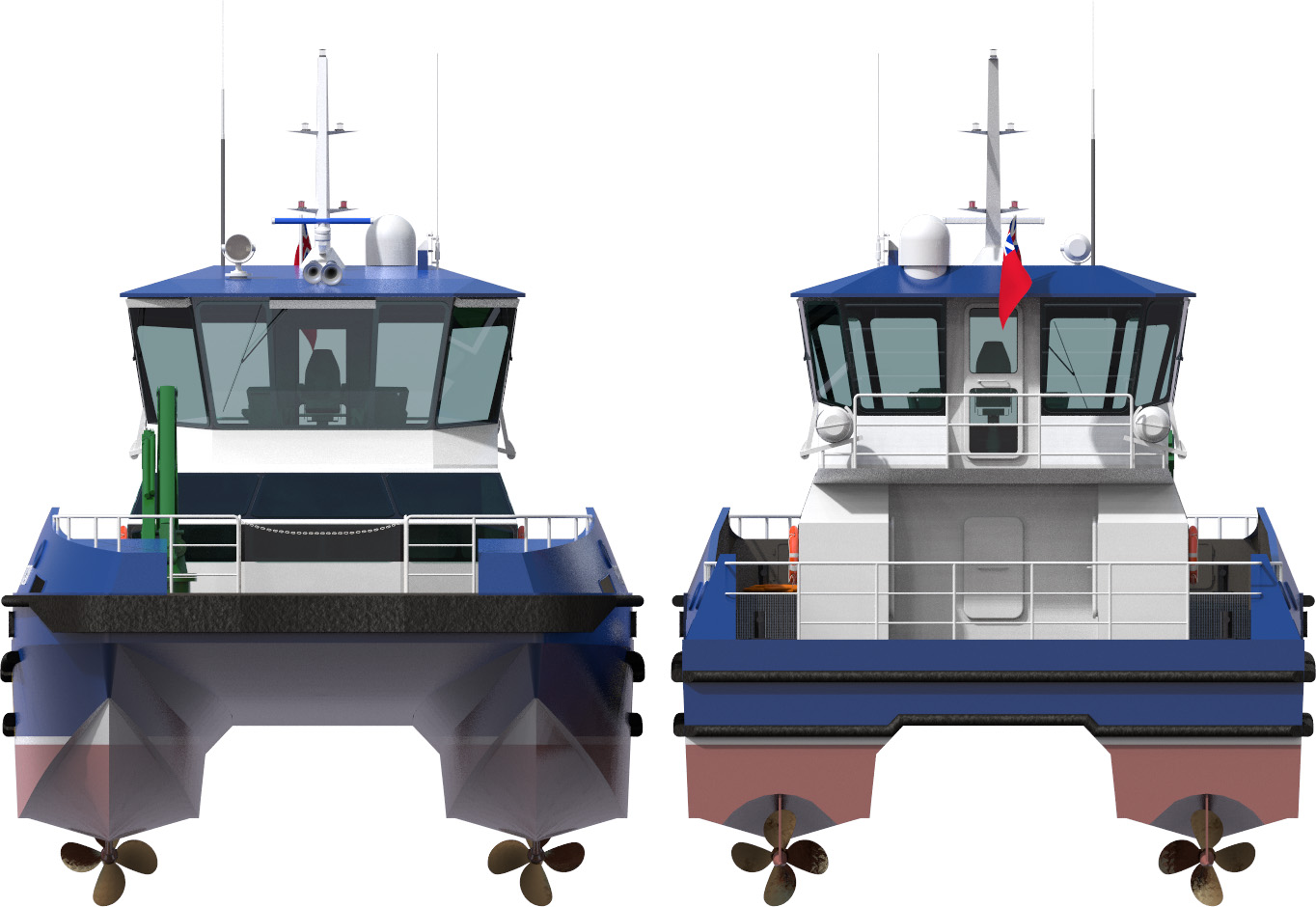

The particulars of the RAptor 2400 are:

- Length Overall: 23.8 m

- Moulded Beam: 8.0 m

- Moulded Draft: 1.1 m

- Methanol Capacity: 12 m3

- Installed Power: 1800 kW

- Speed: >25 knots

Cabins for the master and two crew are in the demi-hull accommodations. A spacious and comfortable technician seating area with large forward and side windows on the main deck accommodates up to 12 wind farm service personnel.

Four Scania DI16 main engines, each rated at 450 kW at 2100 rpm, provide propulsion. Converted to run on methanol by ScandiNAOS, these engines meet IMO Tier III emissions limits without any additional aftertreatment. Two engines in each demi-hull are connected to a dual-input gearbox driving a Servogear controllable pitch propeller system that caters to both maximizing sprint speed and bollard push performance. Extensive in-house CFD analysis was used to achieve a speed in excess of 25 knots at full load displacement.

The CTV has been designed for compliance with Interim Guidelines for Safety of Ships Using Methyl/Ethyl Alcohol as Fuel and Lloyd’s Register Rules for the Classification of Methanol Fuelled Ships.

For more information on the RAptor Class of high-performance wind farm vessel designs developed by Robert Allan Ltd., including crew transfer vessel (CTVs), service accommodation & transfer vessels (SATVs) and compact service operation vessels (SOVs), please contact design@ral.ca.