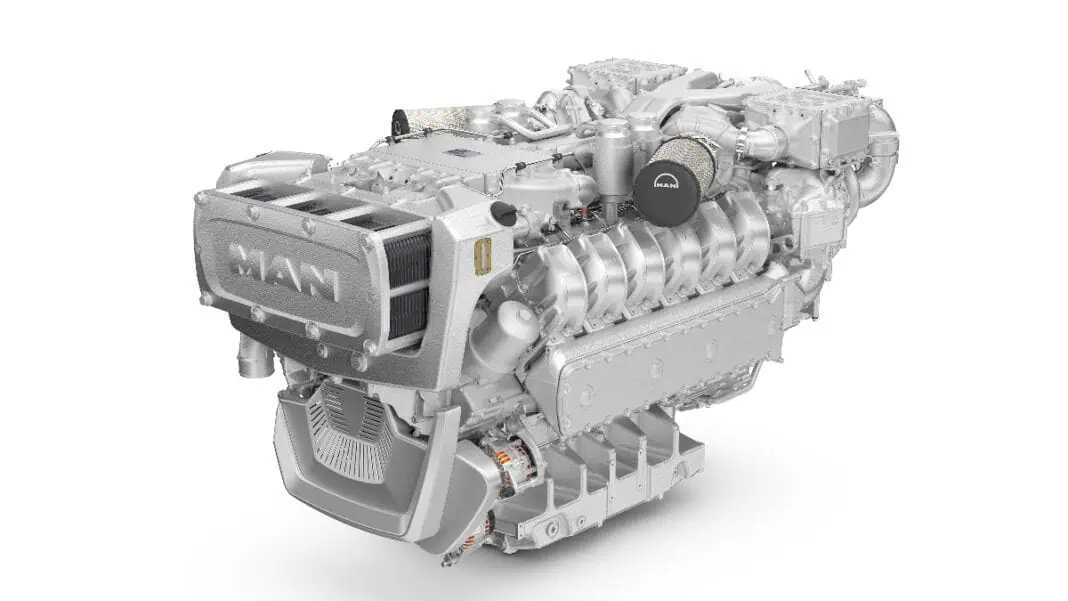

MAN Engines is presenting the MAN D3872 LE432 workboat engine with a displacement of 30 litres for the first time at SMM, shortly before the start of series production. The MAN Engines expands its portfolio of 30-litre engines in the workboat sector engine on display has an output of 1,213 kW (1,650 hp) at 2,100 rpm, making it ideal for medium-duty applications such as wind farm supply vessels (WSV), ferries, passenger ships and fishing boats. Further power variants of the MAN D3872 (1,471 and 1,618 kW or 2,000 and 2,200 hp at 2,300 rpm) for light applications have already started in production.

The MAN D3872 engine has a completely new basic engine that benefits from the findings of the current MAN D2862 V12 engine series, which has been established for many years. Numerous measures have been taken to ensure MAN’s premises of longevity, reliability and future viability. The new V12 engine benefits from improved coolant delivery through a new coolant pump and thermostat housing, which contribute to the engine’s high longevity. As an alternative, the engine is available with an outer skin cooling system instead of a closed cooling circuit. The distinctive cylinder head of the MAN D3872 has also been redesigned to optimise flow and cooling. In addition, the oil supply was adjusted by using flow-optimizing measures in addition to new oil pumps and new oil coolers. The new common rail injection system is another important step for this next generation of engines: with an impressive injection pressure of 2,200 bar, the basis is laid for achieving the low fuel consumption and excellent raw emissions known from MAN engines. The new MD1+ engine control unit also achieves optimum engine tuning.

Another development goal was the high power density, so that the most powerful variant, the MAN D3872 LE433, has an output of 1,618 kW (2,200 hp) and a dry weight of only 2,720 kg and a displacement of 54.7 kW per litre. The developers at MAN Engines were able to retain the connection dimensions of the V12 engine with a displacement of 24.4 litres as well as the compact installation dimensions of 1,153 mm wide and 1,320 mm high. Only the length of the MAN D3872 has been increased by an additional 100 mm to 2,335 mm. In connection with the exhaust gas aftertreatment, which is also very compact and flexibly configurable, the system from MAN Engines offers clear advantages for new buildings as well as repowering projects.

Part of the multi-year development of the MAN D3872 were numerous test bench tests with correspondingly long operating times and additional successful tests at customers in water use. In addition, the MAN E3872 stationary gas engine with the same basic engine is already running extremely successfully in series production and is proving its worth in the field of power and heat generation.

In the medium term, further performance increments are planned for the MAN D3872 marine engine – also for heavy-duty applications – in a wide variety of emission levels.

Today, the MAN D3872 not only complies with the latest exhaust gas regulations, but is also technically designed for use in the MAN Smart HYBRID Experience. In addition, the engine – like all engines from the current portfolio – is approved for use with regenerative diesel in accordance with the EN15940 standard in Europe and the US specification ASTM D975 of the American Society for Testing and Materials (ASTM).

With the new 30-litre MAN D3872 engine, MAN Engines is significantly expanding its engine portfolio in terms of output and displacement. This means that in-line six-cylinder, V8 and V12 engines from 147 to 1,618 kW (200 to 2,200 hp) with a displacement of 12.4 to 29.6 litres are currently available for light, medium and heavy-duty applications.