Miko Marine, aspecialist in marine salvage tools and safety systems, has supplied its customised Blanking Solutions to MODEC’s FPSO Bacalhau, operated by Equinor on the vast Bacalhau field offshore Brazil. Located in the pre-salt Santos Basin approximately 185 km off Ilhabela, São Paulo, the field lies in water depths greater than 2,000 meters. This delivery connects Miko Marine’s advanced underwater repair and safety technology with one of the world’s most advanced deepwater oil developments.

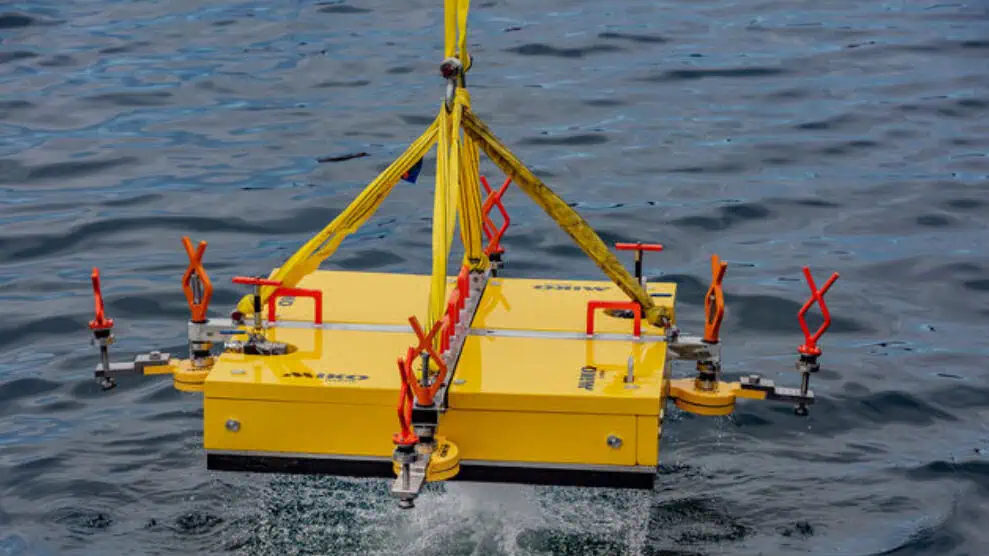

Miko Marine’s custom-engineered ROV-operated cofferdams and pipe covers are designed to temporarily seal or isolate openings in sea chests, inlets, and hull penetrations. These Blanking Solutions are part of Miko Marine’s growing product line for offshore maintenance and contingency operations, providing safe, watertight closures that can be deployed quickly without permanent modifications to the vessel.

Built with lightweight composite and magnetic attachment technology, the covers allow operators to perform underwater maintenance, testing, or isolation work without dry-docking or hot-work.

“Our Blanking Solutions are developed to meet the highest offshore safety standards. Delivering to Bacalhau demonstrates our capability to design and manufacture tailored products for some of the most advanced floating production units in the world”, says Alexander Moen Thue, Managing Director in Miko Marine.

The Bacalhau field represents one of the largest international developments operated by Equinor, with recoverable reserves estimated at over one billion barrels of oil equivalent. MODEC is responsible for the engineering, procurement, construction and installation (EPCI) of the FPSO as well as initial operation and maintenance. The FPSO Bacalhau is based on MODEC’s next-generation M350 hull, measuring 370 m in length and 64 m in width, and can store two million barrels of crude oil.