Ulstein Verft AS, the Norwegian yard, has ordered 2 × 3 × MAN 12V175D-MEV methanol-ready engines in connection with the building of two CSOV (Commissioning Service Operation Vessels) for Bernhard Schulte Offshore (BS Offshore), the offshore unit of international shipping corporation, Schulte Group. The vessels are designed to support the offshore wind-energy market, and are planned for delivery in 2025; an option for four additional vessels exists.

The 175D variable-speed gensets enable the vessels to achieve a significant reduction in fuel consumption and emissions. Each comes with an integrated MAN closed-loop SCR (Selective Catalytic Reduction) system, a compact and flexible solution for the vessels. The MAN 175D gensets also feature reduced structural and airborne noise, as well as the lowest lube-oil consumption.

Mads Faerk, Head of Sales, MAN Energy Solutions Norway, said: “As an industry that provides renewable energy, the spotlight is firmly on offshore wind farms regarding carbon emissions and supply-chain sustainability. Decarbonising vessels in the offshore wind sector has great potential and methanol-ready vessels, which can be converted from running on conventional fuels to methanol without the need for a major refit, are an eminently practical way of achieving this.”

Matthias Müller, Managing Director Bernhard Schulte Offshore, said, “The order for the two newbuildings marks a milestone in the development of our offshore fleet. We are committed to innovating in design and technology to promote the decarbonisation of the maritime industry while supporting the energy transformation and offshore wind power supply. MAN’s innovative 175D engine design is notable for its flexible use of various fuel grades, including biofuel, and its suitability for dual-fuel methanol retrofits.”

Compared to conventional fuels, methanol cuts carbon dioxide emissions by up to 95%, nitrogen oxide by up to 80%, and completely eliminates sulphur oxide and particulate matter.

Florian Keiler, Head of High Speed, MAN Energy Solutions, said: “MAN Energy Solutions’ commitment to decarbonisation focuses not only on future fuels but also on the environmental footprint of the engines itself. From optimising lube-oil consumption, maximising oil-change intervals and with best-in-class times between overhaul, the MAN 175D engine achieves the lowest total cost of ownership. We congratulate BS Offshore and Ulstein on this exciting project and are looking forward to working closely with them in executing it. This first order for MAN 175D DNV-approved, fuel-ready engines proves MAN Energy Solutions commitment to support the marine industry transition into sustainable fuels.”

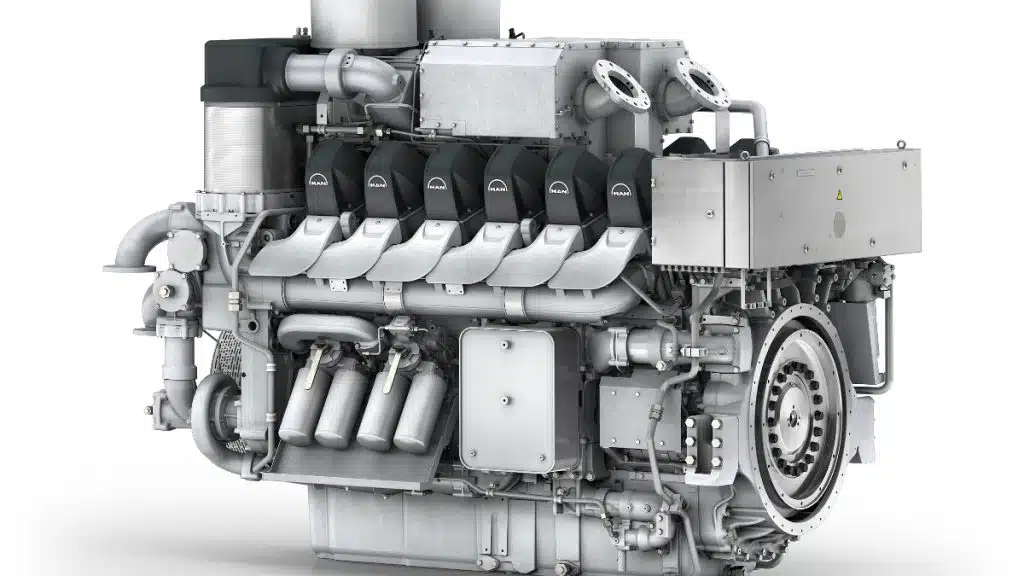

About the MAN 175D engine

MAN Energy Solutions has developed the MAN 175D engine range to supplement and complete its product portfolio in the maritime sector. Available in three variants of 12-, 16- and 20-cylinders, the engine is available with an output ranging from 1,500 to 4,400 Kilowatts and is optimised for propelling ferries, offshore support ships, tugs and other working vessels. Other market areas, such as superyachts, planing yachts and naval marine applications are also served by additional engine variants.

The 175D is also an extremely eco-friendly engine, having been designed from the outset for low fuel consumption, coupled with compliance to the latest exhaust-gas-emission standards and considering as well future-fuel requirements where it is already cleared for operation on biofuels, such as FAME and HVO.