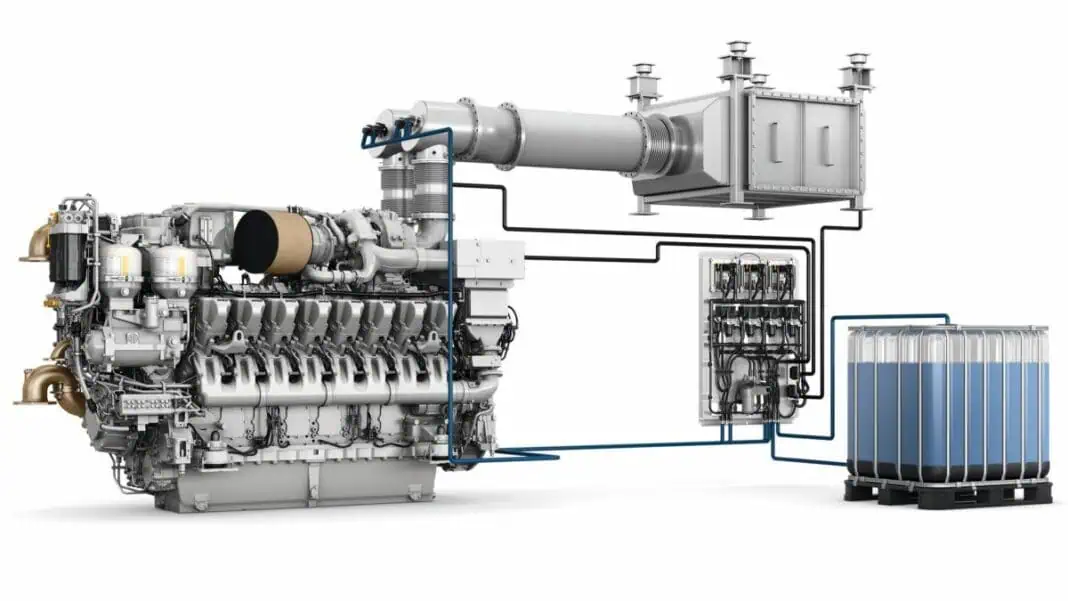

Rolls-Royce is introducing new, more flexible and compact exhaust aftertreatment systems for the 16-cylinder mtu Series 4000 engine, designed for workboats, tugs, and ferries. The latest generation of mtu SCR (selective catalytic reduction) systems requires up to 42% less space and is almost 40% lighter.

Additional benefits include an extended service life of the ceramic SCR material to 18,000 operating hours (depending on load profile) and a 15% reduction in life-cycle costs. Rolls-Royce will also gradually offer the new mtu Flex SCR system across other mtu engines.

“This modular new exhaust aftertreatment system can be even better tailored to the specific needs of our customers and offers them many advantages for their voyages in emission-controlled areas,” explained Denise Kurtulus, Senior Vice President Global Marine at Rolls-Royce Power Systems. Rolls-Royce has set itself the strategic goal of supporting its customers in their business with sustainable and efficient solutions.

Ships with integrated propulsion systems (mtu engines and SCR systems) in the power range between 2,176 and 2,560 kilowatts can be operated in areas with particularly strict emission controls (IMO Tier III). IMO Tier III emission control areas (ECAs) include, for example, the Baltic and North Seas and the North American coast. The mtu SCR system reduces nitrogen oxide emissions by 75 percent compared to IMO II limits.

Rolls-Royce offers its customers maximum installation flexibility: Compared to the previous mtu system, ship operators can save up to 42 percent space with the new Flex SCR. The components can be installed horizontally, vertically, upright, or suspended in the engine room, depending on requirements. Rolls-Royce has also reduced the weight of the new exhaust aftertreatment system by almost 40 percent compared to the previous mtu Cube Box product.

In terms of flexibility, shipyards and ship owners also benefit from the ability to switch the dosing of the reducing agent on and off. This may be the case when they are traveling from one emission-regulated area to another. It is the proven actively controlled system in which emissions are continuously measured upstream and downstream of the SCR system. This ensures optimal and compliant operation of the exhaust aftertreatment system and minimal dosing of the required reducing agent.