Global Survival Technology solutions provider Survitec has launched a pioneering new energy containment safety device designed to reduce the risks associated with catastrophic value actuator failures.

Severe injury or death can be caused by the explosive forces released if a high-pressure spring-loaded actuator device fails, along with significant damage to equipment and facilities. However, there is often a lack of regular inspection and maintenance, and the risks have attracted little attention in terms of technology or regulation.

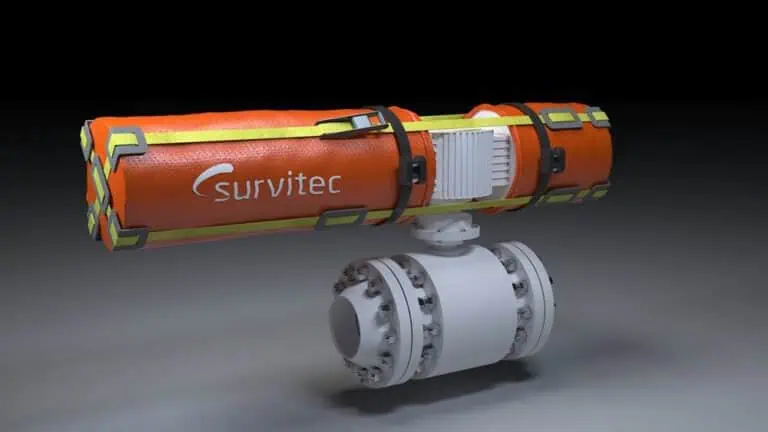

Compatible with all valve actuator types, the Survitec Gauntlet is a protective sleeve constructed from lightweight “bullet-proof” para-aramid armouring, ten times as strong as steel, and designed to contain the unpredictable forces of failure.

Technically qualified by the classification society Lloyd’s Register, the Survitec Gauntlet provides immediate containment protection, enhancing safety measures and minimising potential hazards. It is of minimal weight, placing no additional stress on the actuator, and protects the workings of the actuator from further corrosion and component degradation.

Survitec has supplied its Gauntlets to a majority of operators, including super-majors in the North Sea, and has recently received an order from a Spanish oil and gas operator.

David Montgomery, Head of Sales at Survitec, asserts: “The introduction of the Gauntlet is a testament to our proactive stance on safety enhancement. The absence of detailed regulatory control pertaining to valve actuator failures or maintenance of this critical component is a pressing issue that demands immediate attention. We urge regulators to initiate further discussions and ask operators to act promptly to safeguard their personnel and critical plants in the event of an uncontained failure of an actuator.”

“Valve actuator failures offshore are often due to corrosion and the age of the units, with hundreds of actuators in service on each offshore installation.”

Paul Gwynne, Sales & Contracts Manager at Survitec, said: “The valve return spring sits in a pre-loaded or loaded condition and is powerful enough to close down the valve even during full operation. However, far too many of these actuators have been left to degrade. We are now seeing hundreds in an unsafe or unknown condition – which may be intensified by pneumatic and/or hydraulic control pressures and, therefore, a huge issue and possible danger to equipment and personnel.

“What is known is that many actuators have suffered significant corrosion of the unit’s internal workings, not only the exterior weather shield, which is visible. The problem can be compounded when these actuators are tagged as non-operational or “decommissioned”, no longer serviced but in place, but still containing a pre-load force in the spring, which can be equivalent to several tonnes depending on the size of the actuator.

“There have been a lot of occasions where the spring has eroded to the point of failure, then failed catastrophically, or the retaining bolt and end cap have failed and been ejected. So much so that the UK Health and Safety Executive has advised all operators to enforce action in this area. The force and impact of an actuator failure can be violent and often potentially fatal, impacting people, critical plants and even pipelines.”

The concept of the safety device was developed due to issues identified in the North Sea oil and gas sector, oil rigs, platforms, and floating installations, such as FPSOs and FSRUs. The Survitec Gauntlet can be applied to any facility that operates actuator valves and where risks need to be mitigated.