This summer, sun-seeking tourists looking for a fast ferry service between Dénia, mainland Spain, and Palma and Ibiza in the Balearic Islands will be able to make the trip on a pioneering vessel that combines high speeds with comfortable, eco-friendly operation. The Eleanor Roosevelt is the world’s first fast ferry to be powered by dual-fuel engines that can run on LNG – part of a Wärtsilä integrated solution that combines gas-powered operation with axial flow waterjets and an LNGPac storage and supply system, helping the vessel to ferry passengers more sustainably at high speeds.

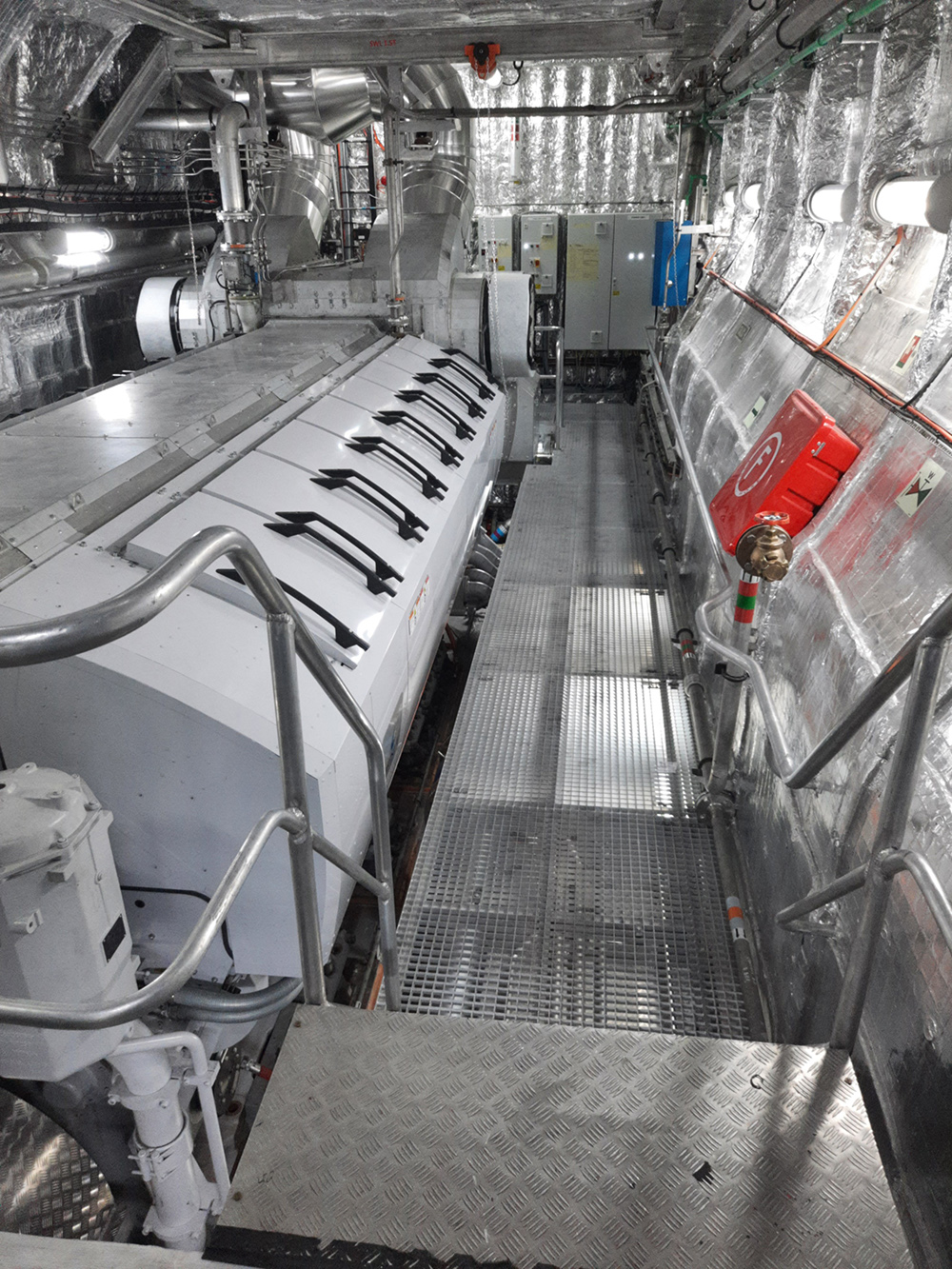

Spanish ferry company Baleària’s commitment to environmental operation has already made it the first operator in Spain to power all its vessels with natural gas. The latest addition to the fleet is the Eleanor Roosevelt – the world’s longest high-speed catamaran and the first fast ferry to operate on LNG fuel. The innovative vessel operates on four highly efficient Wärtsilä 31DF dual-fuel engines, four Wärtsilä axial flow LJX1500SRI waterjets, and a Wärtsilä LNGPac fuel gas storage and supply system. The 125-metre ferry can carry 1,200 passengers and 450 cars – or 500 metres of trucks plus 250 cars – traveling at a service speed of 35 knots and a top speed of more than 40 knots, with storage tanks that give the ferry a range of 400 nautical miles.

Sun, speed and sustainability

Discussions about the Eleanor Roosevelt began in 2017, centring on how best to design a ship that ran on LNG but didn’t sacrifice high speed. Baleària also wanted the design to prioritise customer comfort and service reliability. “By working together from the design phase, we could incorporate all of Baleària’s wishes and requirements together into one integrated design,” explains Jesus Puelles, General Manager Spain & Portugal, Marine Power Sales, Wärtsilä. “High efficiency, reduced operating costs and environmental sustainability were key design values, along with optimised performance for both speed and seakeeping. Using LNG fulfils Baleària’s commitment to the environment, keeps the company ahead of new pollutant gas reduction regulations and ensures the vessel is ready for green future fuels and biofuels.”

No smoke to block the sunshine

Wärtsilä’s engines, combined with the LNGPac fuel gas storage and supply system, meet Baleària’s environmental and performance requirements and when running on LNG can give a reduction in fuel cost of 35-40% compared to diesel operation. The superior efficiency of the engines together with the lower cost of LNG help to considerably reduce the OPEX of the vessel. They also produce no smoke at any load or when starting, which was a key goal to ensure the wellbeing of both ferry users and those who work and live in the harbour area. “The Wärtsilä 31DF represents a new generation of medium-speed engines that offer high efficiency and excellent emissions performance,” points out Puelles. “These four-stroke engines have the best fuel economy of any engine in the class, while maintaining outstanding performance across the complete operating range. Because the engines are designed to operate with longer overhaul intervals, the Eleanor Roosevelt benefits from increased earning potential and reduced spend on maintenance and dry docking.”

“Each year the Eleanor Roosevelt will reduce CO2 emissions by approximately the same amount as eliminating more than 8,900 conventional passenger cars or planting almost 27,000 trees. We are very happy – together with Wärtsilä we have achieved a world first

– Mr. Adolfo Utor, President of Baleària

View all the images from the project

Island hopping in comfort

Wärtsilä waterjets are usually driven by high-speed engines, which have a higher maintenance cost and higher emissions. “For the Eleanor Roosevelt, it was important to Baleària that we use medium-speed engines as they are more efficient with fewer cylinders, leading to lower maintenance costs and lower emissions levels,” explains David van Luijtelaar, Global Sales Manager Waterjets, Wärtsilä. “The Wärtsilä waterjets are axial flow, which reduces the installation footprint by 25% on average and gives a higher power-to-weight ratio, ensuring they fit optimally in the narrow catamaran hull. Wärtsilä axial waterjets also significantly decrease the weight of the installation by up to 20% compared to non-axial jet designs. The waterjets heavily contribute to passenger comfort levels because there is less vibration and noise – in fact, at speeds over 20 knots, noise and vibration are reduced by over 50%.”

All Wärtsilä waterjets have an inboard mounted thrust bearing. “This means that the thrust bearing is not within the water flow of the jet, meaning there is never any risk of oil leaking into the water, making it an environmentally friendly solution.” “Usually the equipment that makes the jets steer and reverse is located outside the vessel and is exposed to sea water,” explains van Luijtelaar. “This means it can be difficult to maintain and repair. Baleària have chosen the ‘inboard hydraulics’ option and installed them inside the vessel, which allows early and easy detection of possible oil leakage.” The Wärtsilä waterjets team is also continuously working on innovative smart solutions that will open up new possibilities for Wärtsilä’s new and existing customers.

Support from design to optimised maintenance

In April 2021, Wärtsilä signed a Wärtsilä Optimised Maintenance Agreement with Baleària, covering the Eleanor Roosevelt for 10 years. The agreement covers all Wärtsilä equipment and provides the security and assurance of technical support on site. “Because safety spare parts stock is included in the agreement, Baleària can ensure vessel reliability while having financial certainty about the cost of spares – including delivery and fitting,” explains Elwin Wilbrink, General Manager Agreement Sales Europe & Africa, Wärtsilä.

Also included in the agreement is Wärtsilä Expert Insight with remote operational support, which uses machine learning and advanced system monitoring to predict problems before they occur, reducing downtime and increasing vessel availability. Measuring equipment and sensors have been installed onboard the ship, making it possible to monitor real fuel consumption and calculate the efficiency of the engines. This allows Baleària to use accurate data to make better informed decisions.

A new standard for high-speed ferries

With excellent environmental credentials, lower lifecycle costs and a high degree of passenger comfort, the Eleanor Roosevelt has set a new standard for high-speed ferries. “Wärtsilä’s unique integration capabilities and high-performance portfolio were important to both Baleària and the Armon shipyard, as were the ongoing service agreement and our commitment to support across the lifecycle of the vessel,” shares Puelles. “Together we have achieved an innovative world first – the longest ever high-speed Ro-pax catamaran and the first fast ferry to operate on LNG.”

“Our commitment to natural gas is a key element of our wider goal to be both socially responsible and economically profitable. The Eleanor Roosevelt is our seventh ship to be powered by LNG, which reduces CO2 emissions by 30% and NOx by 85%.

– Mr. Adolfo Utor, President of Baleària