On the journey towards decarbonisation one thing is for certain: the marine powertrain systems of the future will be more complex, electrified and hybridised setups where smart integration of the various components will be the key to success. Wärtsilä’s new Integrated Systems & Solutions (IS&S) unit was set up to meet this challenge, pooling vast expertise in ship design, powertrain systems, electrification and energy saving solutions into a specialised team. The unit’s director Grant Gassner explains the rationale behind its creation.

“There are three clear pillars that support decarbonisation: alternative carbon-free and carbon-neutral fuels, electrification and efficiency enhancements,” says Gassner. “The goal with establishing the IS&S team is to make it as easy as possible for shipyards, owners and operators to get the maximum combined benefit from our leading technologies in all these areas. This means taking a holistic approach to developing an integrated system – one that delivers significantly higher value than the sum of its individual parts,” he continues.

Unrivalled expertise at your service

IS&S is a 70-strong team established in 2020 to develop and deliver multi-product integrated solutions. The business unit brings together some of Wärtsilä’s top experts in vessel design with vast experience of naval architecture, equipment integration, and simulation and design of electrical and mechanical systems.

“We engage with the customer’s design process as early as possible to fully understand their needs, their business model based on real operative data, and the intended operating profile of the vessel,” Gassner explains.

“Using data-driven design, we then develop a solution that best matches these requirements. This brings together the optimal building blocks of an energy optimised and future-proof system – engines, propulsion systems, and energy storage hardware and software as well as asset management and voyage optimisation tools.

– Grant Gassner, Director, Integrated Systems & Solutions at Wärtsilä

Although the components of each integrated system will vary from vessel to vessel, Wärtsilä is developing configured-to-order, pre-engineered modular elements to speed up the integration and installation processes.

“With a clear functional specification created together with the customer, we can properly manage the system interfaces during engineering and delivery. This takes the pressure off the shipyard because as the OEM we are responsible for handling not just the equipment but its interoperability too,” highlights Gassner. “This means we’re providing a holistic system, not just the parts that make up the system,” he emphasises.

Fuel-flexible engines as the driving force

As engines remain Wärtsilä’s core business, solutions that can take advantage of alternative fuels – whether carbon-free alternatives like ammonia and hydrogen or carbon-neutral options such as green methanol, synthetic LNG, biogas and liquid biofuels – are a key enabler on the decarbonisation journey.

“Ammonia and hydrogen are currently produced from natural gas, but in the future we will see them produced using renewable electricity and water. These carbon-free alternatives offer an immediately viable way to eliminate CO2 combustion emissions,” Gassner explains. “Our engine technologies are developing to enable utilisation of these fuels either in pure mode or as blends with mainstream fuels such as LNG or diesel. As an engine manufacturer it is our job to manage the complexity that these alternative fuels bring in terms of engine and fuel-system design and operation.”

Electrification and energy storage as key enablers

In terms of integrated vessel solutions, electrification is the most relevant of the three pillars supporting marine decarbonisation due to its ability to improve energy utilisation, in particular the wider adoption of hybrid systems that incorporate batteries for energy storage. “Energy storage creates a useful buffer and decouples energy production from consumption,” says Gassner. “This enables your energy-producing assets to operate at maximum efficiency, providing instant power as needed and improving redundancy, load response and power availability. For example, a tug operating at low load can run its engines at optimal load, charge its batteries and then turn the engine off.”

The brain of any hybrid setup is the energy management system. “A hybrid system is only as good as the software at its core, and this is where our world-class energy management capabilities really come into their own,” highlights Gassner. As hybrid systems become more complex, with more producers – such as solar panels, wind turbines and fuel cells – and consumers of power, these capabilities will only become more valuable.

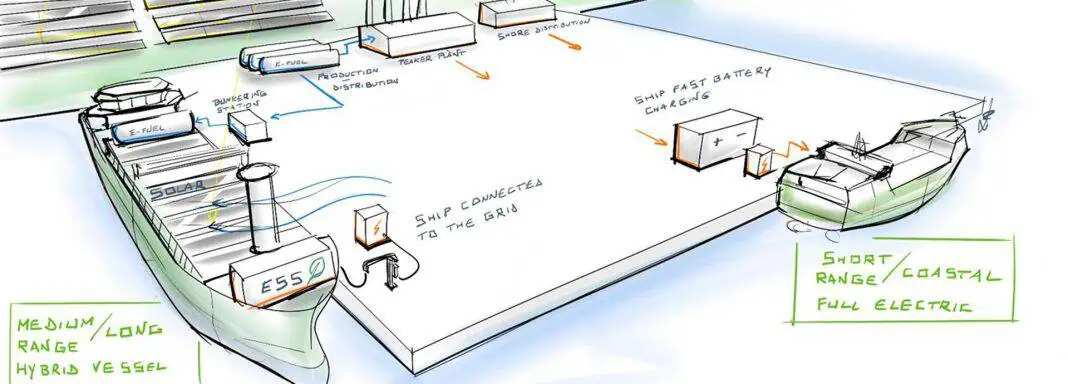

Fully electric solutions powered purely by batteries will also become increasingly common in short-sea and inland applications, and Wärtsilä has already demonstrated its extensive capabilities in delivering integrated equipment solutions for zero-emission ferries. It is also already common to see batteries being integrated onboard larger vessels to enable, among other things, emissions-free operations in ports.

Decarbonising shipping will also require major investments in port infrastructures to support bunkering of alternative fuels, production of eFuels, and large-scale electrical shore connections to facilitate charging and cold-ironing operations. In the future, ports and land-based power generation will play a far more prominent role in providing energy for vessels than they do today.

Efficiency enhancements as standard

At the end of the day the best way to improve the fuel efficiency of a vessel is to reduce the amount of energy it needs in the first place. “Alternative fuels will be expensive, at least in the medium term, so the less a vessel needs the better. That’s why, as our third pillar, we provide a range of efficiency enhancement devices for propulsion,” Gassner points out. Although alternative fuels are in many ways a ‘silver bullet’ to decarbonise power production, their high cost will make the return on investment of new efficiency enhancement systems more attractive.

One example of this type of solution is the Wärtsilä Gate Rudder, which reduces a vessel’s fuel consumption by replacing the drag of a traditional rudder system with a thrust-generating arrangement. Other examples include the Wärtsilä EnergoProFin, which is an energy saving propeller cap that increases overall propulsion efficiency, and air lubrication systems, which use a thin layer of micro bubbles along the hull surface to reduce thrust requirements and decreases the amount of engine power needed to propel the vessel. There will also be greater uptake in the use of sails and Flettner rotors – both of which use wind energy to generate propulsion thrust.

“In the short term the easiest way to reduce power consumption and therefore emissions is to reduce sailing speeds,” says Gassner. “The relationship between speed and required propulsion power is non-linear; for example, reducing the speed of a loaded Aframax tanker by 12% from 17 to 15 knots reduces the propulsion power requirement by about 35%.

Voyages might take a little longer when sailing at lower speeds, but they become far more efficient on a grams of CO2 per tonne-mile basis, which is the criteria for the IMO’s Energy Efficiency Design Index (EEDI) and Energy Efficiency Existing Ship Index (EEXI).

Wärtsilä can also add real value with its smart digital technologies for voyage planning, route optimisation and performance management that help vessels get from A to B just in time and as efficiently as possible, taking into account variables such as port congestion, ocean currents and wind conditions that could for example affect propulsion efficiency of future vessels equipped with sails.

Control what you can and be prepared for what you can’t

“Our customers are currently burdened with a sense of uncertainty and overloaded with the vast number of potential routes open to them towards low and eventually zero-carbon operations,” Gassner says. “Investing now in vessel designs that incorporate dual-fuel engine technology and hybrid electric propulsion provides owners with the peace of mind that comes with knowing that their vessel will be flexible and therefore future proof.”

For example, investing in dual-fuel engines with LNG now provides a solid platform for utilising ammonia, which can use the same tanks, in the future.

“Whatever the future brings, more complex, electrified, hybridised, integrated and smarter systems will be the norm, and Wärtsilä’s IS&S unit is a response to that reality. Vessels will need fuel-flexible engines, alternative sources of power, and propulsion energy-efficiency devices as well as flexibility in their operational profile.”

It is important to remember that many of these alternative power sources and efficiency-enhancement devices are intermittent in nature. Installing multi-engine dual-fuel electric-hybrid main propulsion today with energy storage secures the needed flexibility to integrate intermittent sources and alternative fuels both in the newbuild phase and later in the vessel lifecycle as retrofits.

“Working with IS&S, yards and vessel owners benefit from having the equipment, interfaces, software and project management handled by one expert supplier. This brings peace of mind in the form of a single efficient, streamlined and sustainable whole that is easy to manage, maintain and enhance. Wärtsilä is also developing in parallel Lifecycle Asset Management capabilities to handle more complex systems. This will enable owners to fully exploit the potential of integrated systems throughout the vessel’s lifecycle via a Lifecycle Service Agreement,” Gassner concludes.