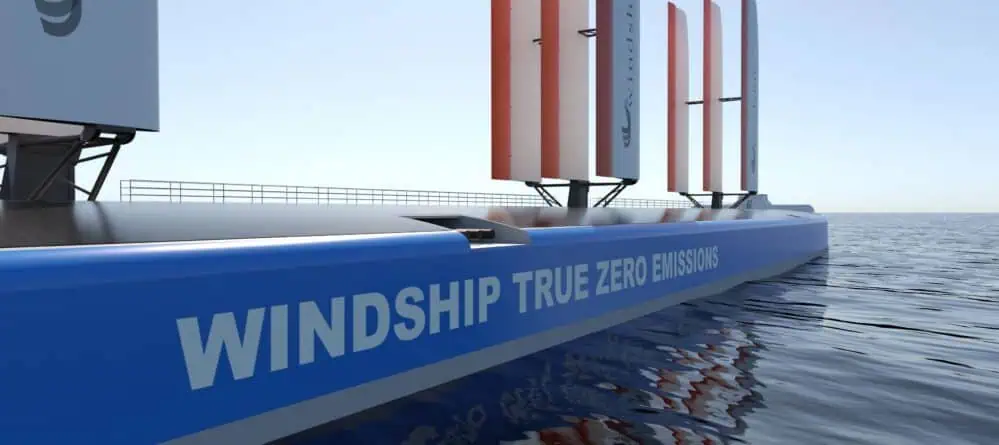

Windship Technology, Britain’s leading True Zero Emission company for the shipping industry today announces their patented triple-wing rig has received a coveted ‘Approval in Principle’ (AiP) status from shipping classification society DNV.

This significant milestone in the company’s history is the result of years of design iteration work combined with the use of cutting-edge CFD to refine the wings before extensive wind tunnel testing and analysis by independent third parties. Each wing has trailing edge flaps that allow for optimisation of the motive force produced for a variety of incident wind angles and, crucially, allow the rigs to produce the highest power density of any current wind-powered solution. With three rigs set, they can produce all the power required to sail an 80,000 DWT ship on the main long transoceanic routes.

Speaking about the classification, Simon Rogers, Technical Director at Windship Technology stated: “This is the classification that changes everything. Now it is abundantly clear that the shipping industry has a workable solution to its significant emissions issues. Fleet owners and charterers have a zero emissions option with Windship Technology’s whole-ship design that is set to revolutionise the industry and the need for these wing solutions has never been more than now. With the Energy Efficiency Existing Ship Index coming into force on 1st January 2023, the clock is ticking on the shipping industry. Windship Technology is the stand-out solution and we welcome the Approval in Principle from DNV whom we have worked with efficiently and expediently in achieving this classification.”

Windship Technology is leading the innovation not only in rigs but also in its overall solution for Zero Emission shipping. The design starts with the rigs, constructed from composite materials to reduce weight at height, and goes further with an incorporated diesel electric drive featuring a full carbon capture system that dramatically reduces fossil fuel consumption whilst eliminating NOx, SOx and particulate matter and zero CO2.

The wings deployed on vessels are located on a steel cruciform base which provides the intersection with the ship and also house the lifting and lowering mechanism – especially important for port access and bridge height clearance. The rigs can be lowered either fore and aft or over the ship’s side as required for loading and unloading operations. Whilst underway, the rigs are automatically controlled, rotating to gain the greatest motive advantage from the available wind power.

As the Approval in Principle for Windship Technology’s tri-rig was announced, Hasso Hoffmeister, Senior Principal Engineer, DNV Maritime said: “As shipping’s carbon trajectories head towards zero and the EEXI and CII are set to tighten requirements – the maritime industry needs new options to reduce emissions. At DNV we want to support our customers by making sure that when they are looking to make efficiency gains, they have well proven and well tested options. This is why we are so pleased to be working with Windship Technology, to help them build confidence in their Wind Rig system through the application of expertly verified models and data, based on our long-standing and globally accepted rules

Graham Harvey, Chief Executive of Windship Technology welcomed the news; “This is a terrific milestone for the whole team at Windship Technology and we are now in a position to capitalise on the multiple discussions that we have been having with owners and charterers who are all looking for long-term solutions. It’s wonderful that a truly innovative, British company is leading the way in finding a true zero emission solution and we would like to thank the team at DNV for their assistance in helping us bring this much-needed solution a step closer to reality.”