Pipelaying ships are used in subsea infrastructure construction projects to install rigid and flexible pipes and umbilicals in water depths up to 3000 meters. Due to the extreme masses and lengths of the pipes being laid deep onto ocean floors, the reliability and safety of onboard systems is of the utmost importance.

Skeleton Technologies and MJR Power & Automation have cooperated on a first-of-its-kind pipelay extended supply failure ride-through system in one of the largest pipelaying ships in the world, improving the capabilities and safety of the system.

Pipelay Failure Ride-Through System

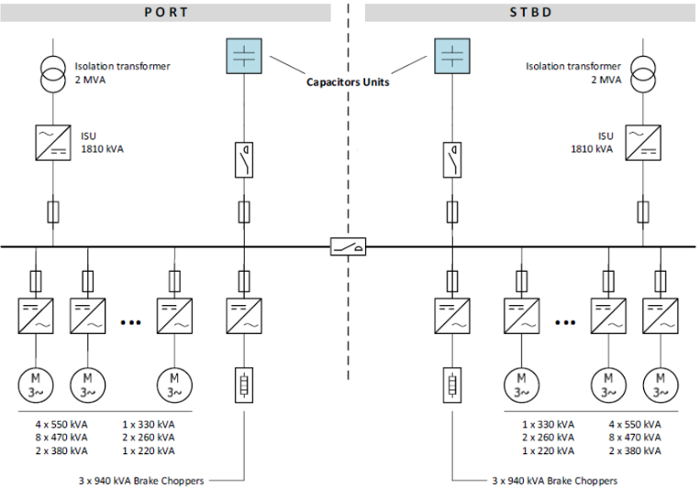

The vessel pipelay tower has tandem upper and lower tensioners. The port drive system supplies the upper tensioner and various winches located on the back deck. The Starboard drive system supplies the lower tensioner and various items of equipment on the pipelay system. In pipelaying operations, it is essential to rule out any possibility of blackouts during operations and ensure synchronization between the tensioners and the reel. Skeleton’s energy storage solution provides immediate back-up power, bridging any gap in power until the main back-up system can respond.

System schematic

The system improves the operational safety of the vessel, while enabling addition benefits to customer:

- Increased equipment availability and product protection

- Non-intrusive installation and low risk to existing system operation

- Optimal solution for both CAPEX and footprint compared with alternative storage options

- Lifetime operation with millions of cycles of operation and low maintenance

- Proven technology

Project Highlights

- First supercapacitor system globally to comply with DNV-GL Part 6 chapter 2 and

be certified by DNV-GL - Turnkey solution from concept through to delivery and commissioning

- Retrofit to existing machinery drive systems with minimal modification of existing

install - System fully tested at MJR Factory before vessel installation

MRJ Scope of Supply

- FEED Study

- Basis and detailed design for Power, Electrical & Automation

- DNV-GL marine classification system approval

- Construction

- Installation & Commissioning

Skeleton Scope of Supply

- Supercapacitor energy storage system design and production

- Supercapacitor integration engineering

Skeleton and MJR Power & Automation have a long history of working together in marine projects, combining Skeleton’s expertise in energy storage and MJR’s expertise in offshore and marine engineering and projects. Read more about our cooperation with active heavy systems.