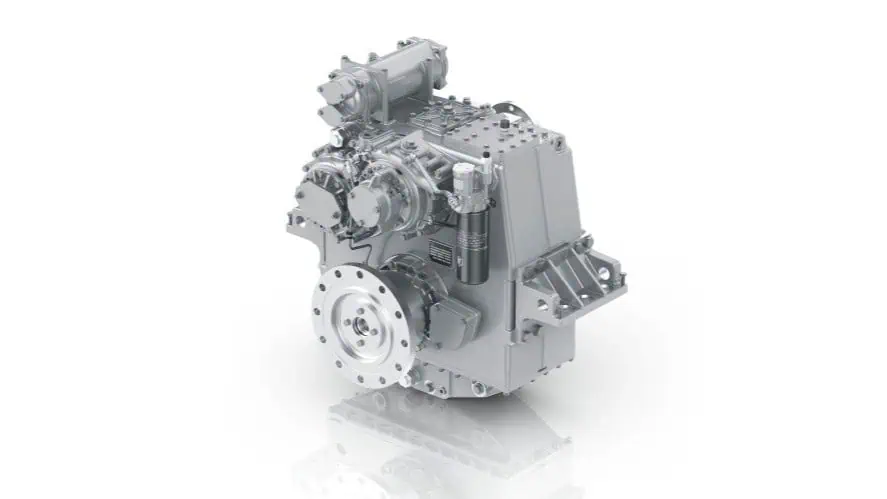

ZF, a global leader in driveline technology, unveils its new ENC series – the company’s first marine transmission developed explicitly for purely electrically powered vessels. It impresses with its optimised efficiency on electric motors, outstanding lightweight design and excellent NVH behaviour. This improves the electric range, comfort on board and ongoing operating costs – and supports shipyards and operators in the transformation to more sustainability.

According to forecasts, the global market for electrically powered ships is expected to grow to 17.20 billion US dollars by 2032. By comparison, it was just 4.33 billion US dollars in 2024. This proves that electromobility in shipping is not a short-term trend, but – in more than one sense – a sustainable development on global waters.

Near the coast or on shorter routes, the development even extends to pure battery-electric drives. These are a sensible alternative to conventional or hybrid units wherever a corresponding charging infrastructure can be set up comparatively easily. “With our new ENC transmission series, we now have an optimal solution in our portfolio for these applications to support the industry in its sustainable transformation,” says Wolfram Frei, Sales Manager Commercial and Fast Ships at ZF.

The new ENC series is the first transmission series from ZF that is explicitly intended for use in pure electric vessels. Experience from past projects was incorporated into the development. In Portugal, ZF had already equipped passenger ferries with electric drive solutions a few years ago to cross the Tagus River with zero local emissions. At that time, it was a conventional transmission that was tailored to this requirement. “After this successful project, our motivation was to further optimise the efficiency of battery-electric drives. This paved the way for the development of the new ENC series,” says Frei.

The ENC series was designed in such a way that the drive power of the electric motor is optimally transferred to the propeller even at high speeds and high ratios – a common scenario in electric shipping. This improved efficiency reduces energy consumption, delivering a greater range and better economy.

Unlike conventional and hybrid transmissions, this transmission series dispenses with a hydraulically actuated multidisk clutch (ENC = electric non-clutchable). As a result, the oil supply quantity can be significantly reduced, since a ‘peak consumer’ is also eliminated by omitting the clutch. In addition, the system oil pressure can also be lowered. Both factors ultimately result in a smaller oil pump and also increase mechanical efficiency. Depending on the customer’s requirements, the oil volume is supplied either via an electrically operated pump or a bidirectional mechanical pump.

ZF also lowered the oil level. “This reduces churning losses, which increases efficiency,” says Frei. Thanks to the smaller pump, the lower oil level and further structural optimisations, the ENC transmission weighs considerably less – up to 10% compared to similar solutions, depending on the version.

Another development focus was on the acoustic properties to meet the special requirements of electric motors. The ENC therefore stands apart with its outstanding NVH behavior.

The ENC series can be combined with all maritime ZF drive solutions, from the ZF 2000 to the ZF 9000. It thus covers a power range from 650 kW to 3,900 kW. It is suitable for all installation configurations (A/V, U, Z), center distances, attachments, transmission ranges as well as for fixed propellers, variable pitch propellers and waterjet drives. “This provides shipbuilders with optimum flexibility in the design of the electric vessels,” explains Frei. “The ENC is therefore ideally suited to electrify the operation of commercial vessels such as ferries, tugs, supply boats or river cruise ships on short routes.”

Thanks to decades of expertise, ZF can rely on proven standard components as well as the existing, worldwide service network of ZF Aftermarket for the production of the ENC. This ensures the supply of spare parts.

The new product is already attracting specific customer interest. “We have inquiries from Portugal, Scandinavia, the USA,” says Frei. And concludes: “This proves that sustainable ZF driveline solutions, as well as electromobility, are a global issue.”