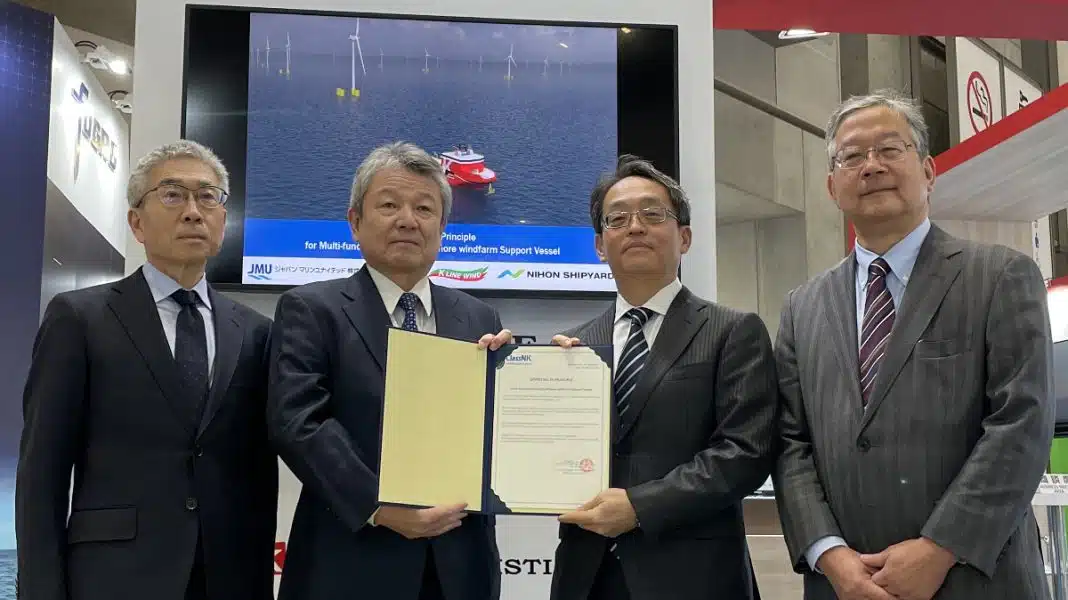

ClassNK has awarded an approval in principle (AiP) for the design of a multi-functional floating offshore windfarm support vessel (MFSV) developed by “K” Line Wind Service, Ltd., a joint venture of Kawasaki Kisen Kaisha, Ltd. and Kawasaki Kinkai Kisen Kaisha, Ltd, together with Japan Marine United Corporation and Nihon Shipyard Co., Ltd.*1

The installation of floating offshore wind turbines requires mooring works by vessels, with the whole mooring system composed of an anchor, a mooring chain, and a fiber rope. The MFSV, developed this time, is designed to perform whole mooring works efficiently for floating offshore wind turbine installation, including “transportation of mooring system”, “deploying mooring system on the seabed”, and “anchor tensioning”. According to the companies, the vessel also features a multi-functional concept, providing various vessel solutions in each phase of offshore wind projects such as “Survey”, “Transportation”, “Construction”, and “Operation & Maintenance”.

ClassNK carried out the design review of the MFSV based on its Part O of Rules for the Survey and Construction of Steel Ships for work-ships and SPS Code*2, as well as IP Code*3, which will enter into force from July 2024. Upon confirming it complies with the prescribed requirements, ClassNK issued the AiP.

ClassNK will continue to contribute to the further expansion of renewable energy through its activities as a certification body.

*1 The development of this design concept is subsidized by Japan’s New Energy and Industrial Technology Development Organization (NEDO) as a part of Green Innovation Fund Project “Technology development project for basic manufacturing and installation cost reduction for floating wind turbines”.

*2 Code of Safety for Special Purpose Ships

*3 Code of Safety for Ships Carrying Industrial Personnel