The increased performance of the SCHOTTEL RudderPropeller Dynamic SRP-D has been confirmed again by external experts. At the request of the Dutch Damen Group, the Maritime Research Institute Netherlands (MARIN) carried out extensive research to demonstrate the benefits of the SCHOTTEL SRP-D Confirmed by MARIN for Commissioning Service Operation Vessel (CSOV).

While an earlier study had already demonstrated a reduction in the DP footprint and fuel savings, Damen’s latest study focused in particular on propulsion efficiency during interactions between the drive unit and the hull and when the drives are in mutual flow. The results show a significant increase in thrust and a reduction in the “forbidden zones” with the SRP-D compared to conventional rudder propellers.

“In our continuous endeavour to offer our customers optimal vessels, SCHOTTEL’s developments are a major step forward,” says Mark Couwenberg, Product Portfolio Manager SOVs at Damen. “The SRP-D drives, mounted under Damen’s optimised hulls, ensure vessels with a smaller footprint, while at the same time reducing fuel consumption and further improving on-board comfort. Combined with SCHOTTEL’s robust design, construction and manufacturing methods, we are convinced that our customers will benefit from this combination for a lifetime.”

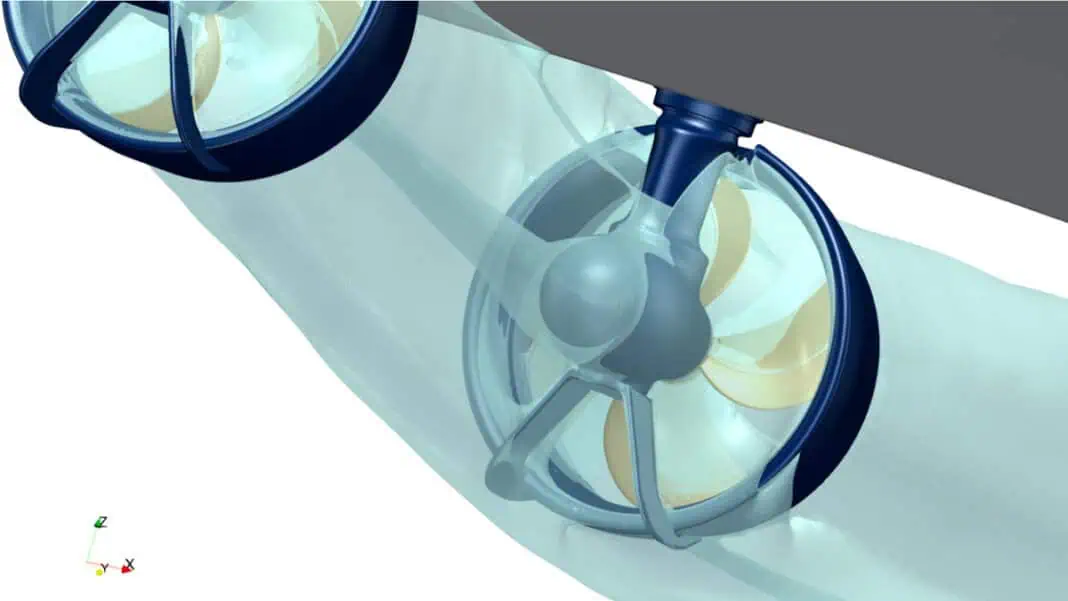

With the SCHOTTEL SRP-D Confirmed by MARIN optimized for DP operation, SCHOTTEL meets the increased requirements for efficiency and reliability for CSOV vessels. The drive has a propeller shaft inclined by eight degrees and a vertically integrated electric drive motor (LE-Drive). In addition, the SRP-D is characterized by shortened acceleration/deceleration times of the propeller. In combination with high-speed azimuth control with reinforced gear components, the SRP-D enables faster thrust allocation than conventional rudder propellers. Thanks to the shorter reaction times, it is possible to react more quickly and precisely to external forces such as wind and current, thereby achieving greater positioning accuracy of the vessel.

The investigation was carried out on a model of a CSOV equipped with a SCHOTTEL RudderPropeller Dynamic on the starboard side and a regular 90-degree drive on the port side. To carry out the tests, the model was placed in a 45-meter-long and 36-meter-wide offshore basin and equipped with a three-component measuring frame with calibrated sensors for data acquisition.

In the first part of the study, the interactions between the propulsion unit and the hull were measured. It was found that the SRP-D propeller shaft, which is additionally inclined downwards by eight degrees, can significantly reduce thrust losses at different azimuth angles and system thrusts. For example, CSOVs with 98-degree drives only experience 10 percent thrust loss in the transverse direction, compared to 35 percent for 90-degree drives. As the study shows, a reduced Coandă effect is a key factor in the improved system performance of the SRP-D.

The second part of the study focuses on the interactions between the systems. Here, too, significantly lower thrust losses occur with SRP-D-powered CSOVs: While 50 percent losses are observed when the 90-degree drive is directed at the second drive (“in-line thrust losses”), only 20 percent thrust losses occur with the 98-degree drive. If the 90-degree drive is directed at the second drive while it is perpendicular to it (“transverse thrust losses”), the transverse thrust is reduced by around 40 percent compared to 20 percent with the 98-degree drive. In both cases, the 98-degree variant thus leads to lower losses on the other drive than the 90-degree variant and therefore enables a higher remaining thrust during dynamic positioning.

As the study shows, the SCHOTTEL RudderPropeller Dynamic ‘s eight-degree inclined propeller shaft significantly optimises thrust yield and thrust distribution, as the interactions between the drive unit and the hull as well as the mutual flow of the drives are reduced. As a result, the “forbidden zones” of the drives can be reduced, which leads to an additional increase in the ship’s DP performance. In addition, CSOVs can significantly reduce their fuel consumption. Overall, the ships operate much more efficiently and safely and extend their operational time throughout the year.