Propspeed, leading innovator of underwater foul-release coatings announces its attendance at Seawork and its partnership with Marine Protection Systems. Together they aim to educate and provide innovative solutions to prevent corrosion and minimise damage to commercial vessels and the marine biosphere.

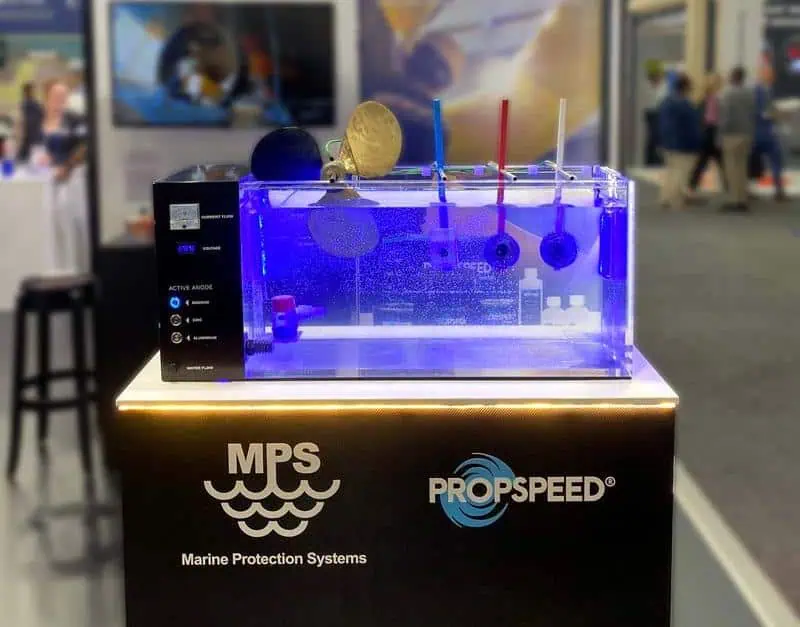

The insulative properties of Propspeed combined with correct anode solutions greatly improve efficiencies, reducing fuel burn and operational costs, while also minimising the environmental impact that corrosion and coating loss has on the oceans. Propspeed teamed-up with anode technology manufacturer Marine Protection Systems (MPS), to create the world’s first Corrosion Protection Tank that would show the relationship and performance of various anodes and coatings.

The Corrosion Protection Tank demonstrates how Propspeed’s two-part coating system can reduce the risk of corrosion by electrically isolating the metal and limiting exchanges between ions and gases contained in the water and the metal.

“Our team is continually developing key partnerships in tangential technologies to help our customers better understand how ours and other products they choose work together, to protect their underwater assets,” said Chris Baird, CEO, Propspeed.

He added: “While our product line is known for eliminating the adhesion of marine growth, it is also an excellent corrosion inhibitor. This new partnership will demonstrate the importance of selecting your anodes at the same time as selecting your underwater coatings. This is going to be a very informative demonstration.”

“We have worked towards establishing a reputation as a market leader in the manufacture of anode technology and other vessel infrastructure that improves cathodic protection and efficiencies,” said Jess Gatt, General Manager, Marine Protection Systems. “Propspeed’s very knowledgeable staff are excellent at educating their customers on the benefits of Propspeed. Since their products work hand-in-hand with ours, we believe they are the perfect partners to collaborate with.”

The Propspeed two-part coating system features an exceptionally strong chemical and mechanical bond between the metal substrate; the Etching Primer and the Clear Coat, which eliminates adhesion of marine growth and inhibits corrosion.

The Propspeed Etching Primer is known for its iconic gold colour, tenacious adhesion to metal substrates and superior corrosion resistance. The Propspeed Clear Coat provides a super slick surface that marine growth cannot adhere to. Together these form a coating which ensures optimum vessel performance throughout the entire service cycle.

Visitors to Seawork will be able to see daily tank demonstrations on the Propspeed stand A25 at 11am and 3pm. For further details regarding Propspeed’s partnership with Marine Protection Systems watch the video at www.propspeed.com/mps.

Propspeed is effective on all underwater metal surfaces including propellers, shafts, rudders, struts, keel coolers, pod drives, thrusters and fire suppression pumps.

Propspeed products include Propspeed for running gear and any underwater metals, Foulfree for transducers and Lightspeed for underwater lighting. For more information, please visit www.propspeed.com/commercial.