Siemens Digital Industries Software – Using CFD to enable better decisions early in the design process leads to lower lifecycle costs – Case Study

Founded in 1974, Teignbridge Propellers International (Teignbridge) is a world-leading designer and manufacturer of marine propulsion and stern gear products. With over 65,000 square feet of floor space and over 100 employees at its headquarters in Southwest England, it is the largest producer of its kind in Europe, renowned for continually optimizing the performance of ships of all sizes, from yachts and patrol boats to tankers and military vessels. Teignbridge manages everything from the engine and gearbox to the back of the vessel. This includes the couplings, shafts, bearings, seals, stern tubes, brackets, propellers and rudders.

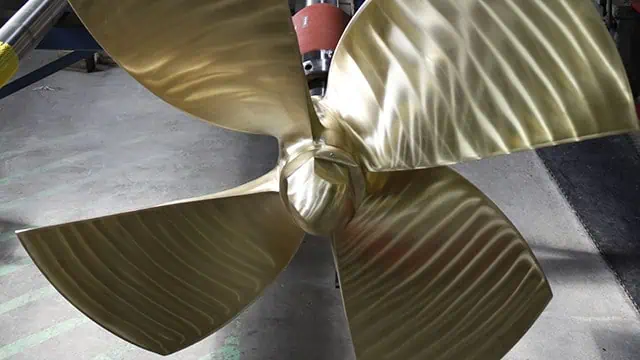

Regardless of the size of a propeller, which could be up to 8 meters (m) in diameter, changing the design by just one millimeter (mm) can noticeably impact both efficiency and performance. Therefore, Teignbridge uses computational fluid dynamics (CFD) simulations to not only develop the best possible designs but also ensure the highest level of manufacturing precision.

“With the latest significant investment in enhancing production precision, we’re able to manufacture the propeller to within the accuracy of a hair,” says Mark Phare, group managing director at Teignbridge. “Now whatever the engineers design, we can replicate it perfectly in the finished product.

“Ensuring design and production accuracy are paramount for our business as we are acting on a global scale and we can’t fly out or keep shipping parts to fix possible issues. We need to get it right the first time, every time.”

Stricter maritime regulations

The International Maritime Organization (IMO) and the Marine Environment Protection Committee (MEPC) set the regulations for the industry. In the past, their requirements have been guidelines but now they are becoming much more strictly enforced. IMO has put in place a strict emissions mandate to reduce carbon dioxide (CO2) output by 50 percent by 2050 and introduced an energy efficiency index for new designs and existing ships. It will be impossible to make this kind of significant reduction without innovations. It is vital that Teignbridge makes full use of the latest technology to stay ahead of the competition, meet all the industry regulations and build leading-edge components that deliver optimum performance.

As Saeed Javdani, innovation and technology manager at Teignbridge, explains, “It is important for us to be on top of the game and design products with the required index, improving the product efficiency and reducing emissions.”

Harnessing the power of CFD simulations

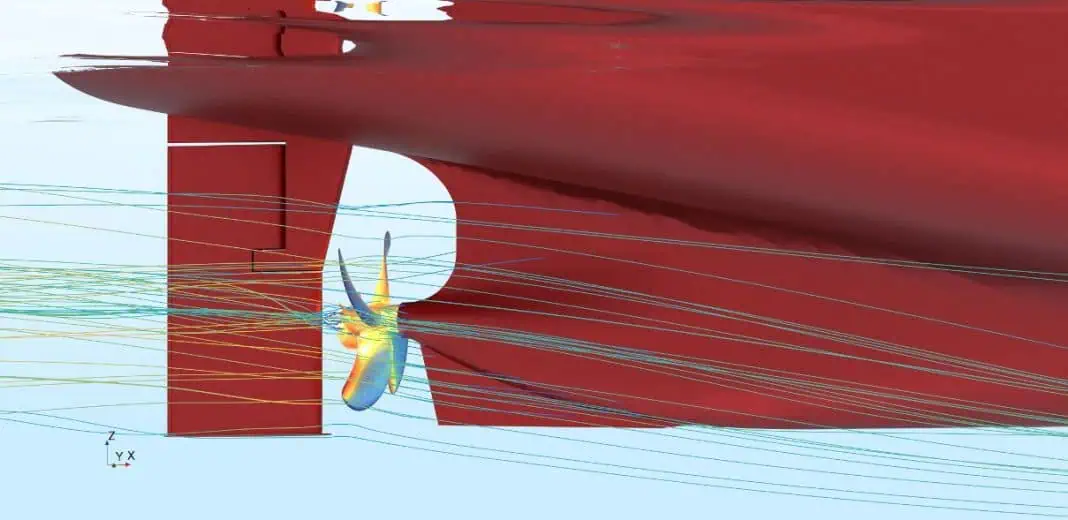

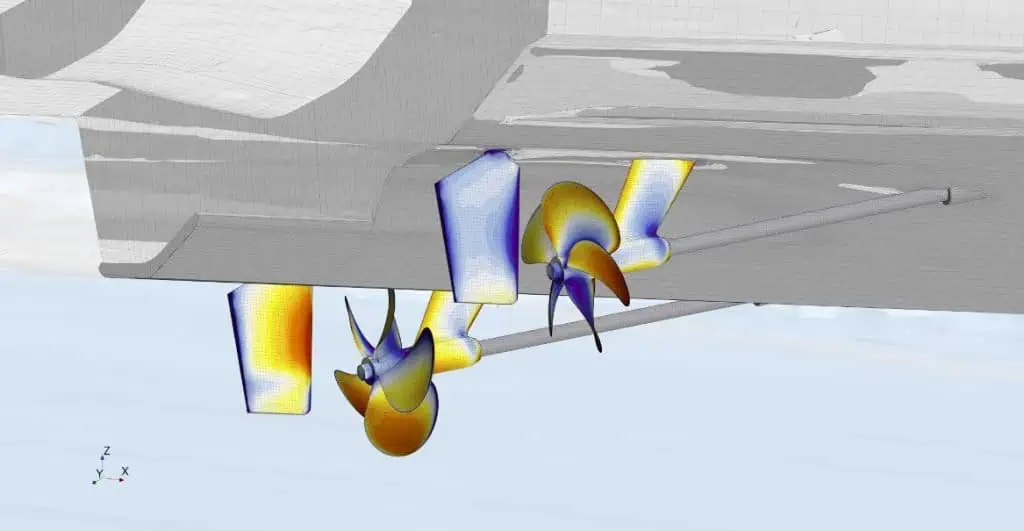

To meet these challenges and optimize designs, Teignbridge uses Simcenter™ STAR-CCM+™ software to run fast and accurate CFD simulations that evaluate a variety of complex phenomena, aiding designers to understand the interaction between propulsion systems and the high-velocity water flowing across their surfaces. Teignbridge conducts these activities with the support of Maya HTT, a Siemens Digital Industries Software solution partner.

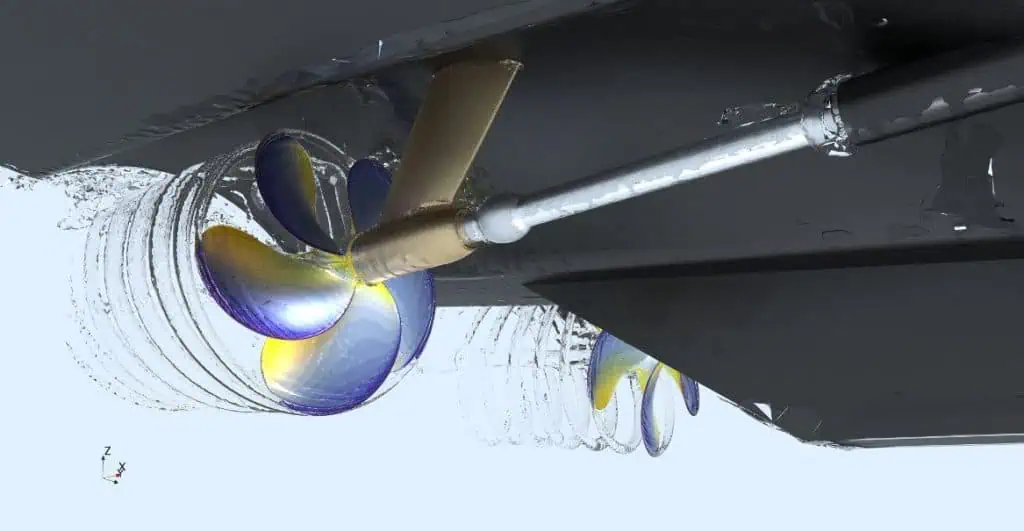

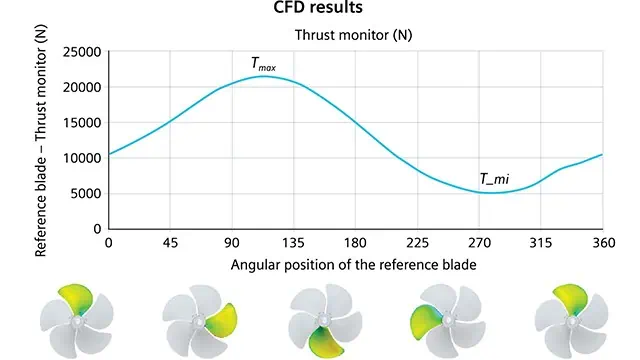

Understanding cavitation – where vapor bubbles in a fluid grow and collapse due to local pressure fluctuations – allows engineers to predict the impact on propulsion performance, durability and noise. The simulations help them predict the location, extent and type of cavitation and modify designs to minimize it.

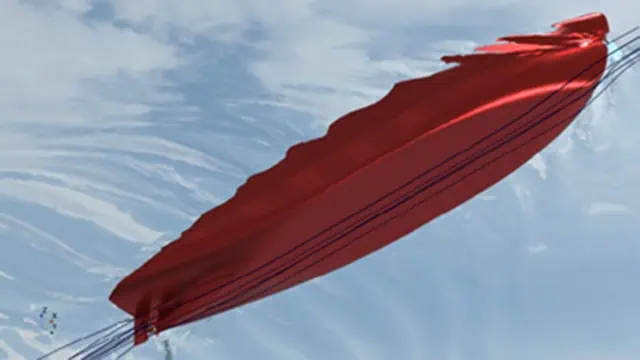

Engineers also use Simcenter STAR-CCM+ to optimize components for the entire propulsion system to ensure their influence on the water flow complements the propeller’s design. In one instance, they identified areas of low pressure on the leading edge of a rudder that could cause cavitation and noise. By redesigning the rudder and carefully aligning its leading edge to the downstream rotational flow from the propeller blades, they also managed to increase the vessel’s top speed by around 2 knots.

By using computer-aided engineering (CAE) and Simcenter simulation tools all these performance improvements are made before any of the components even get wet. This allows for crucial decisions to be made much earlier in the design process, leading to increased efficiency, reduced costs and improved products.

According to Phare, the shipbuilding industry is embracing innovation in design and manufacturing. “We see that designs are becoming far more accurate as we’re taking into account a lot more factors. With CFD simulation we’re able to predict the wake field coming into the propeller, and how the flow can be affected by the bracket in front and the rudder behind. Meaning, we are able to evaluate the system as a whole rather than the individual parts.”

Javdani says Simcenter STAR-CCM+ is vital to his team’s development processes: “You need sophisticated tools that can predict your hydrodynamic loads and how your propulsion system will behave under different operating conditions. We used to just consider one or two design points, but with Simcenter STAR-CCM+ we can predict how the vessel will perform at different speeds and in different sea conditions. Simulation makes it possible to explore many more iterations in less time so we can come up with the optimal design.”

Crucially, this technology allows engineers to consider the entire ship as a system rather than just a collection of individual components. They can place their propulsion systems inside vessels in a virtual environment to understand how they will interact.

“Now we can go back to the ship designers and give them suggestions for improvements,” says Javdani. “We can explain how they can make changes to improve the flow into the propulsion system during the design stage before anything has been built. So with Simcenter STAR-CCM+ we are not only optimizing the design of our components, but we’re also helping shipbuilders to achieve the maximum propulsion performance for their vessels.”

Reducing noise pollution

Protecting the environment involves more than just designing propulsion systems that use less or cleaner fuel. Noise pollution can have a damaging effect on marine life and biology: “If you want to save the planet, save the oceans,” remarks Javdani. He says the capabilities of Simcenter STAR-CCM+ are critical to analyzing noise generation and adapting designs to reduce it. “We can predict lower frequency ranges relatively easily but the higher frequency range, typically caused by the turbulence in the flow and the collapse of cavity bubbles within the downstream of the propeller, is much more complicated. With CFD simulation we can accurately predict and optimize our designs. Every vessel has a unique acoustic signature in the form of the underwater radiated noise it generates, so the simulations help us reduce the amplitude and mask the signature as much as possible.”

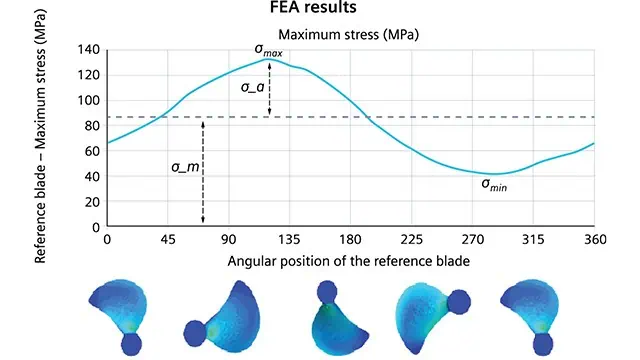

Javdani explains why Teignbridge selected Simcenter solution as the best tool to use in these analyses: “We don’t have to combine Simcenter STAR-CCM+ with another software package because everything is in one place. The procedures, tools and techniques are all intuitive and well documented, so it makes life much easier for us. With the built-in linear finite element analysis it’s simple to set up a fluid structure interaction to analyze the propeller within the whole flow.”

Optimizing performance

When designing new components, it is critical for Teignbridge to provide their customers with an accurate indication of the efficiency and performance improvements they will deliver. Using Simcenter STAR-CCM+ numerical simulations and CFD analysis allows engineers to predict what effect design changes will have, leading to the development of velocity-aligned rudders and brackets.

For example, a customer had a boat with a target speed of 34 knots, but it was only achieving 31.8 knots. By adding a velocity-aligned rudder, it was able to achieve the required speed. In another case a customer needed to reduce the radiated noise level by 10 decibels below 1,000 Hertz (1 kHz). Using CFD, Teignbridge achieved about a 15-decibel reduction.

Using HEEDS™ software enables the firm to explore as many design iterations as possible – up to 500 iterations in 48 hours – to find the most optimum design. Simcenter STAR-CCM+ and HEEDS are part of the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services.

“Running so many iterations is simply not possible without HEEDS,” says Javdani. “Trying that many designs manually would take far too long and wouldn’t be cost-effective.

“We’re also working on the design of new devices that reduce the energy efficiency index of the propulsion system. Devices such as propeller boss cap fins (PBCFs) can be built into the design at the start or they can be retrofitted to an existing propeller. Essentially, it’s a smaller propeller attached to the main propeller that recovers energy from the rotating flow of the blades.”

CFD as a common language

Teignbridge also needs to prove to the classification societies that new components will meet their safety requirements. “Simcenter STAR-CCM+ enables us to show the relevant authorities that new designs will meet their standards before they are even built,” says Javdani. “Fatigue analysis is important to them. Without CFD we wouldn’t be able to give them the level of detail they need.”

Using CFD as a common language makes it much easier for designers to show classification societies that all their requirements are being met early in the development process. “For instance, we can show that new components will still perform within the safety factor required under dynamic loading,” says Javdani.

Classification societies and customers appreciate Teignbridge’s decision to adopt CFD. “Although we have nearly 50 years of experience in designing propellers and shaft lines, the addition of CFD analysis provides extra reassurance to our customers,” says Phare. “Incorporating CFD into our design toolbox has been essential to the progression of our designs in recent years. Many of our customers use Simcenter STAR-CCM+, which enables us to easily share data and talk the same language when evaluating new projects. Most naval architects and designers expect propulsion designers to have CFD capabilities and to offer an analysis of the underwater equipment at the design stage.”

Seeking to be the best

Phare is clear on his vision for the future: “We want to be the world-leading designer and manufacturer of propulsion equipment. To do that we need to produce the best components and deliver the best customer service.” Javdani adds, “Simcenter STAR-CCM+ has enriched the scope of work and sparked a great deal of innovation at Teignbridge. It helps us to better understand exactly what customers need, and also helps us solve problems they didn’t even know they had. We can now design and supply products that we weren’t able to previously, opening up new markets and establishing ourselves as the go-to company within the industry.”

Many of our customers use Simcenter STAR-CCM+, which enables us to easily share data and talk the same language when evaluating new projects.

Mark Phare, Group Managing Director

Teignbridge

Source: Siemens Digital Industries Software – Using CFD to enable better decisions early in the design process leads to lower lifecycle costs