When it comes to thrusters it’s all about maneuvering and station keeping in the safest, most accurate and energy efficient way possible. Wärtsilä Propulsion’s Thruster business line has over 50 years’ experience in designing, manufacturing and optimising thrusters, with one of the widest portfolios in the industry. Lauri Tiainen, Director of Thrusters & Propulsion Control Systems at Wärtsilä, talks about thruster trends, product innovations and the benefits of optimised solutions.

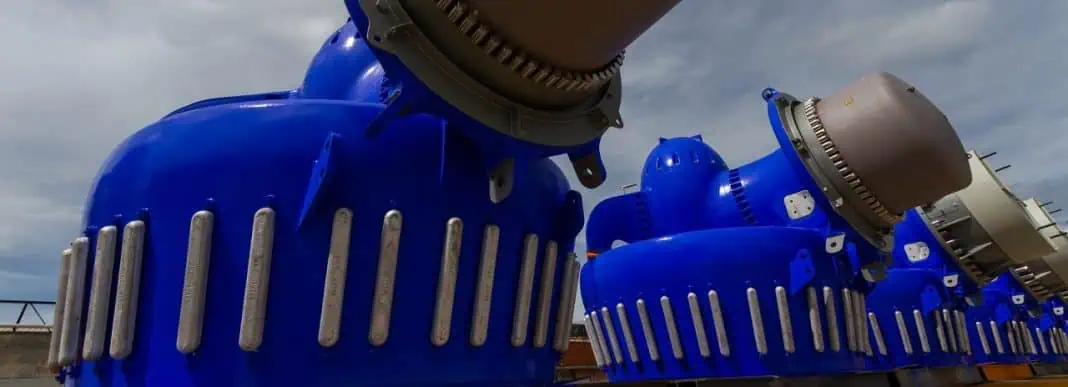

“Our customers own and operate every sort of vessel, from tugboats and merchant ships to some of the most advanced vessels currently operating, like drill rigs, shuttle tankers and offshore vessels performing demanding and dangerous work,” begins Tiainen. “And we serve them all with one of the widest portfolios on the market, covering steerable (azimuth), retractable and transverse (tunnel) thrusters. Thrusters are used to provide greater manoeuvrability, for accurate station keeping, and to allow ships to be independent from tugs. They also provide a high level of redundancy and can help increase a vessel’s speed, lower the requirements for installed power or reduce fuel consumption. But achieving these benefits isn’t easy – making a thruster requires experience. And if you want to develop a thruster that works optimally, is durable, energy-efficient and easy to maintain over its lifecycle, you need decades of experience!”

Always innovating

“Technology is constantly developing so we are always looking for new ways in which we can improve station keeping and manoeuvrability for our customers. Not only do we have years of hydrodynamics experience within the Thruster team itself, but we also have the help of our friends in the Technology unit, who apply their industry-leading skills in computational fluid dynamics (CFD) to help us optimise thruster configurations, reduce hydrodynamic losses and achieve the highest possible energy efficiency.”

“We also put our experience to good use developing innovative features for our products, such as the unique plug-and-play design of our retractable thrusters,” explains Tiainen. “The thruster comes pre-assembled and aligned, reducing the complexity of installation as all that is needed is for the thruster to be lowered into place, levelled and secured. Even remote commissioning is possible if required. We have also developed a new type of retractable thruster with a downward tilted propeller shaft that eliminates hydrodynamic losses. Traditionally thruster gearboxes are at a 90-degree angle, which means the water flow interacts with the hull and can take away up to 20% of the thrust the unit has created. Our gearbox is tilted at 8 degrees, which gives almost zero hydrodynamic losses as it doesn’t interact with the ship’s hull, leading to an energy efficiency improvement of up to 20% compared to traditional systems.”

Working together to make things work together

“One reason we achieve such good results with our thrusters is because we have such a wide breadth of knowledge within Wärtsilä and we understand the importance of integration and designing to achieve the optimal outcome,” points out Tiainen.

– Lauri Tiainen Director of Thrusters & Propulsion Control Systems at Wärtsilä

“Nothing works in isolation so to get the best results we integrate thruster packages with other vessel systems like dynamic positioning (DP) and engine control systems. Integration also helps us to make sure that installed equipment takes up the minimum space onboard – for example, our plug-and-play thrusters allow a great deal of installation flexibility with no space, or only minimal space, required for auxiliary equipment.”

Lauri Tiainen Director of Thrusters & Propulsion Control Systems at Wärtsilä

Accurate station keeping and manoeuvrability for ever-larger vessels

“In several segments the industry trend is for larger vessels, with cruise ships, container vessels and offshore vessels, in particular, all increasing in size,” observes Tiainen. “This means more power is needed for the vessel to manoeuvre, which generally requires more thrusters but can also sometimes be achieved with better thruster optimisation. We offer both transverse and steerable thrusters to guide the movement of vessels, allowing our customers to carry out sophisticated operations, ensure accurate station keeping and maintain a high degree of manoeuvrability.

“Our large transverse thrusters – some of which are actually far more powerful than the main propulsion systems on the vast majority of the world’s cargo ships – are particularly relevant in the cruise industry as we have developed the design to minimise the disturbance of water flow, which delivers a smoother sailing experience for passengers. Our thrusters also give cruise ships the manoeuvrability required to be independent in port operations so they don’t need to rely on tugboats.”

“Offshore vessels are also getting larger and working further from shore carrying out very complex operations, such as cable laying or windfarm installation,” continues Tiainen. “Conditions out at sea can be incredibly demanding so the very best dynamic positioning is needed to keep vessels exactly where they need to be – for this you need thrusters and a high-performance DP system. We have a long track record in achieving extremely accurate station keeping for some of the largest, most complex vessels operating in the toughest conditions in the world.”

Optimisation brings significant measurable benefits

“For these large, specialist vessels we use our CFD expertise and our simulation tool to optimise the whole vessel, helping to provide the lowest possible CAPEX and operational efficiency,” shares Tiainen. “For both transverse and steerable thrusters, we can tailor the product to the final needs of the owner, with the exact thrust and power output needed. We can offer even more value from the partnership in the early stages of a project – in one case we helped to optimise the number of thrusters suggested by the vessel designer without changing the total power, saving costs while expanding the operational window in which the vessel will be able to maintain its position.

“We also had a recent case where, by specifying more smaller thrusters instead of fewer larger ones, we found a 30-tonne weight-saving opportunity for a complex jack-up vessel. That’s 10% of the total thruster weight, which is hugely important because every additional tonne is more payload for the vessel to lift. Our thruster optimisation also reduced CAPEX by over 10% and improved the manoeuvrability of the vessel. This shows what we can achieve if we’re involved early.” These jack-up vessels are also a good example of where the entire integrated thruster system, and communication between each component, must be flawless because even a small mistake at a critical moment could cause major issues for the operator.

Helping ships of all sizes become more efficient

“One thing that every segment has in common is the desire for energy efficiency and the need to contribute to the maritime industry’s decarbonisation and sustainability targets,” points out Tiainen. “This is a never-ending journey for us as we are constantly striving to do more to support decarbonisation through product design and research and development. All our thrusters are available with environmentally acceptable lubricants (EALs) and are fully compliant with all environmental regulations globally; in addition, our hydrodynamic knowledge and technical CFD expertise helps to reduce fuel consumption, which reduces emissions and operational expenses. When you buy a thruster from us you are buying efficiency, accurate station keeping and superior manoeuvrability, with support from vastly experienced experts that understand your challenges and can help optimise your vessel – that’s what makes us stand out from our competitors.”