Two SCHOTTEL RudderPropellers type SRP 710 have left the German production site in Wismar and are on their way to the Turkish shipyard Med Marine for installation in a new tug. The salvage tug, which has been ordered by Kenya Ports Authority (KPA) will be equipped with main and auxiliary propulsion systems from SCHOTTEL. By this, the vessel will achieve an expected bollard pull of more than 120 tonnes. The Robert Allan RAstar 4200 (MED-A42120) design vessel is considered the largest tugboat on the East African Coast of the Indian Ocean.

SCHOTTEL thrusters for highest bollard pull

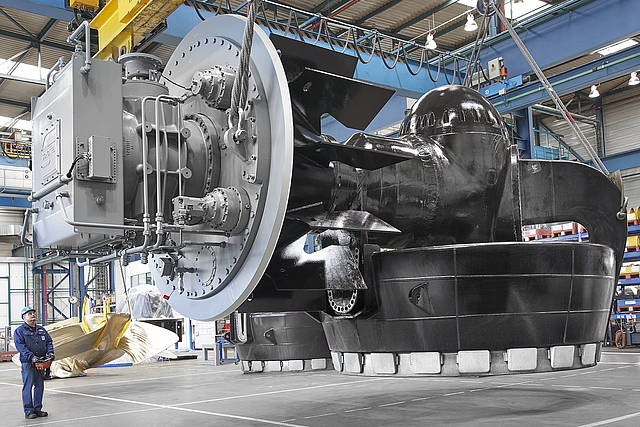

The new vessel will be driven by two SCHOTTEL RudderPropellers type SRP 710 with an input power of 3,700 kW each at an input speed of 1,000 rpm. The SRPs feature propellers measuring 3.4 metres in diameter. The azimuth thrusters will be powered by diesel engines. Furthermore, one hydraulically-driven SCHOTTEL Transverse Thruster type STT 170 (250 kW) will ensure maximum manoeuvrability.

With input powers of up to 3,750 kW and propeller diameters of up to 3.6 m, the SRP 710 is one of the larger rudder propellers in the SCHOTTEL portfolio. They are manufactured at the Wismar production site in Germany.

Enhancing efficiency at the port

This highly effective propulsion system will enable the tug to provide more efficient ship handling and coastal towing services. Measuring 42 metres in length at a width of 16 metres, the salvage tug is equipped with extensive towing facilities, extinguishing monitors for firefighting, external bilge systems for leak detection, workshops, ship cranes and dinghies.

The state-of-the-art vessel will be a vital addition to East Africa’s largest port of Mombasa.